Small Vacuum Loading Machine

Small Vacuum Loading Machine is a compact conveying device based on the vacuum principle, designed for small batches and short distances of powdered or granular materials.

Belt Material: Stainless Steel

Voltage: 380V / Customizable

Application: Product Conveying

Frame Material: SUS304 Stainless Steel

Capacity: 10 kg - 10 tons/hour

Length: Customizable, 1-100 meters

Conveyed Materials: Granular and powdered products

Applicable Industries: Laboratory R&D, small-scale food production, fine chemicals, and auxiliary material conveying for the 3C industry

What is a Small Vacuum Loading Machine?

Small Vacuum Loading Machine is a lightweight device designed for small-batch, short-distance material transport. It typically occupies less than 1 square meter and weighs between 50 and 200 kilograms. It can be flexibly installed in either a mobile or fixed configuration. Its highly integrated structure allows for immediate use without complex installation, making it particularly suitable for space-constrained environments such as laboratories and small workshops.

What types of small vacuum loading machines are there?

Based on their power source, small vacuum loaders can be categorized into two main types: pneumatic and electric. These two types differ significantly in their operating principles, application scenarios, and performance characteristics.

Pneumatic vacuum loaders: Powered by compressed air, they generate negative pressure through a Venturi tube or pneumatic vacuum pump. They have no moving parts, such as a motor, and are compact, lightweight, and mobile. They are suitable for high-purity environments such as workshops handling flammable and explosive materials and in food and pharmaceutical production.

Electric Vacuum Loaders: Relying on 220V/380V electricity, electric motors drive scroll and vane vacuum pumps. They provide stable negative pressure and continuous output power, extending the range of conveying capacity. They are suitable for medium-volume continuous production, continuous feeding on small production lines, quantitative batching systems, and workshops that don't require explosion-proofing but require automation.

What are the advantages of a Small Vacuum Loading Machine?

Small vacuum loaders are compact and space-saving, offering fully enclosed conveying for dust prevention. They are easy to operate and adapt to a wide range of materials while meeting cleanliness standards, reducing costs and ensuring safety.

Flexible and Portable: Small size and light weight, some models feature universal wheels for easy movement to different workstations and adaptability to multiple scenarios.

Simple Operation: No specialized training is required; parameter settings are easily set using buttons or the touchscreen, making it easy for even novice operators to get started.

Small Footprint: The vertical design occupies less than 1 square meter, allowing for flexible installation next to production lines or in confined spaces. Flexible Layout: With a horizontal conveying distance of 50 meters and a vertical height of 30 meters, it easily spans multi-story factories, addressing the layout limitations of traditional conveying equipment.

Low Price: With a lower purchase cost than larger equipment and lower energy consumption, it's ideal for small businesses or laboratories with limited budgets.

Small Vacuum Loading Machine Model Specifications

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

Small Vacuum Loading Machine Workflow

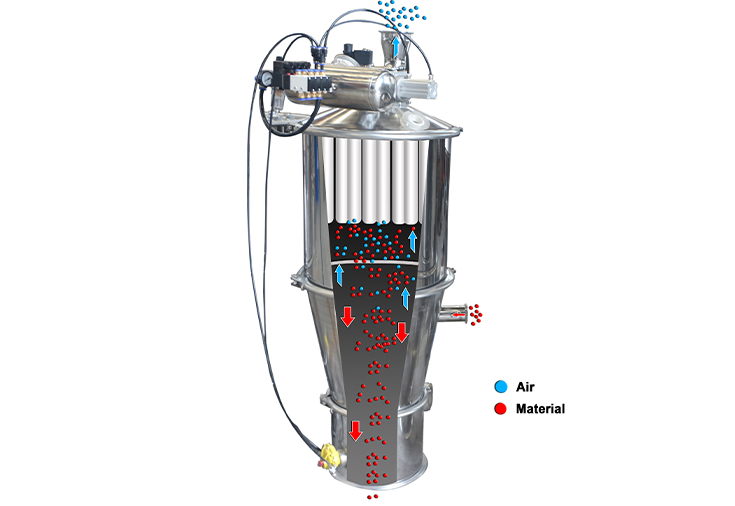

The operating principle of the small vacuum loader is the same as that of larger equipment, based on negative pressure adsorption technology, but with a more streamlined process.

Vacuum Generation: A built-in micro vacuum pump rapidly extracts air from the hopper and conveying pipe, creating a negative pressure environment of -0.02 to -0.06 MPa.

Material Intake: Due to the pressure differential, material is drawn into the conveying pipe from the intake port and then into the hopper.

Air-Material Separation: A simple filter within the hopper separates the material from the air, allowing the material to remain in the hopper while clean air is discharged. Automatic Unloading: When the material in the hopper reaches the set volume, the vacuum pump stops, the discharge valve opens, and the material falls by gravity into the target device. The system then resets and begins the next cycle.

Comparison between Small Vacuum Loading Machines and Traditional Manual Dosing

In small-batch material conveying scenarios, the small vacuum loader competes with traditional manual dosing, focusing on efficiency, cleanliness, and safety.

| Comparison Dimension | Small Vacuum Feeder | Traditional Manual Feeding |

| Conveying Efficiency | 0.1-2 tons/hour, continuous and stable, error ≤2% | <0.5 tons/hour, fluctuates greatly due to physical strength |

| Cleanliness | Fully enclosed conveying, dust leakage ≤0.1mg/m³, no impurity mixing | Exposed operation, dust flying, prone to impurity mixing |

| Operational Safety | Non-contact operation, equipped with anti-corrosion/explosion-proof design, no risk of occupational injuries | Direct contact with materials, prone to lumbar muscle strain, safety hazards when contacting corrosive materials |

| Applicable Scenarios | Laboratories, small food/pharmaceutical workshops, multi-batch small-volume production | Extremely small-scale production or simple scenarios without automated equipment |

Where Can the Small Vacuum Loading Machine Be Used?

Small vacuum loaders are suitable for laboratory trials, small food workshops, and small-batch production of fine chemicals. They are also suitable for pharmaceutical R&D, bakeries, and electronic auxiliary material processing, providing flexible and fast delivery.

Laboratory R&D: In pharmaceutical and chemical laboratories, they are used to transfer small doses of powders and granules, avoiding material waste and contamination caused by manual dosing and ensuring the accuracy of experimental data.

Small Food Production: Suitable for bakeries and small candy factories, they convey raw materials such as powdered sugar and grain granules, meeting the needs of small and multi-batch production while complying with food hygiene standards. Fine Chemicals: For conveying small batches of materials such as pigments and additives, corrosion-resistant materials are available to prevent chemical reactions between materials and equipment.

3C Industry Auxiliary Material Conveying: In electronic component production, trace auxiliary materials such as solder powder and insulating particles are conveyed to ensure that no impurities are introduced during the conveying process.

How much does a Small Vacuum Loading Machine cost?

Small Vacuum Loading Machines start at as low as $800, with a variety of configurations to meet different needs. The basic pneumatic model has a simple structure and is suitable for small batch material conveying. Priced between $800 and $1500, it is an economical choice for occasional conveying of small amounts of powdered materials in laboratories. The electric standard model has a slightly larger conveying capacity of 0.5 to 1 ton/hour and comes with basic automation, making it suitable for continuous feeding in small production lines. Customized features, such as food-grade 304 stainless steel required by the food industry, explosion-proof features required by the chemical industry, or integration with an intelligent control system for precise automation, will increase in price depending on the complexity of the features. If you would like a detailed quote, please contact us!

Small Vacuum Loading Machine Manufacturer

Our small vacuum loaders offer a full range of models, including pneumatic, electric, explosion-proof, and food-grade models, widely used in the pharmaceutical, food, chemical, and new energy industries. Focused on "speed, cleanliness, and intelligence," our company employs a modular design and supports customizable solutions. Our equipment boasts a conveying efficiency of 6 tons/hour, a dust leakage rate below 0.01 mg/m³, and is compatible with multi-language PLC control and IoT remote operation and maintenance. We also offer customers one-stop material handling solutions and customized solutions.

With its "small and beautiful" design, the Small Vacuum Loading Machine has redefined the standard for industrial material handling. From laboratory research and development to large-scale production, and from traditional manufacturing to emerging industries, this equipment is experiencing a 15% annual market growth, becoming a key component in driving the advancement of smart manufacturing.