Vibro Sifter Metal Powder

The Vibro Sifter Metal Powder, with a price range of $600 to $5000/Set,is designed for precise metal powder grading, classification and purification in jobs such as powder metallurgy, 3D printing and alloy production.

Voltage 380V / 3PH / 50hz

Screen Mesh:2-500 Mesh

Capacity:100Kg-10Tons/hour

layer:1-5 layers

Motor power:1.5-7.5kW

Material: Stainless Steel 304/316L

What is Vibro Sifter Metal Powder?

Vibro Sifter Metal Powder is a machine used for particle size classification, impurity removal and purification of metal powders. It plays a key role in powder metallurgy, 3D printing, alloy preparation and other scenarios. Different machine models should be matched for different mesh ranges of metal powders. For example, coarse particle powders with mesh sizes of 20-100 have good fluidity, so linear vibrating screens are preferred for rapid classification. Medium and fine powders with mesh sizes of 100-300 need to take into account both accuracy and efficiency, so they are more suitable for rotary vibrating screens. Ultrafine powders above 300 meshes are easy to agglomerate and clog the screen, so a vibrating screen with an ultrasonic system is required to break up the lumps through high-frequency vibration to avoid clogging the screen.

The physical properties of metal powder directly affect the selection of screening machine. Magnetic powder is easily adsorbed by ordinary metal screens, so anti-magnetic material screening machine should be selected to reduce interference; ultra-fine powder that is easy to agglomerate needs to be equipped with ultrasonic devices to destroy the agglomeration structure through high-frequency vibration; corrosive powder must use 304/316L stainless steel screening machine to improve corrosion resistance; metal powder with high density has a large dead weight, so it needs to be matched with a heavy-duty rotary vibrating screen or a reinforced linear screen with a stable structure to ensure the stability of the screening process.

How to classify Vibro Sifter Metal Powder?

Vibro Sifter Metal Powder can be divided into three common models: rotary vibrating screen, linear vibrating screen, and ultrasonic vibrating screen. Different metal powders have different matching models.

Linear vibrating screen: suitable for processing coarse metal powders of 20-100 mesh, such as iron powder, copper powder, lead powder, etc. This type of powder has a large dead weight and good fluidity. The large amplitude and high frequency of the linear screen can quickly separate large impurities. The hourly processing capacity of a single device can reach 10 tons, which is suitable for large-scale coarse powder screening.

Vibro Sifter: Suitable for processing 100-300 mesh medium-fine metal powders, including stainless steel powder, aluminum alloy powder, zinc powder, etc. This type of powder has medium particles and moderate fluidity. The multi-layer screen of the vibro sieve (2-5 layers are optional) can simultaneously complete multi-level classification, taking into account both accuracy and efficiency, and is suitable for small and medium batch fine screening.

Ultrasonic vibrating screen: Suitable for processing the agglomeration and clogging problems of ultrafine metal powders above 300 mesh, such as nano nickel powder, titanium powder, carbonyl molybdenum powder, etc. This type of powder has a small particle size and is easy to agglomerate. The high-frequency vibration of the ultrasonic vibrating screen can break up the agglomeration. Combined with the low adsorption characteristics of the 304/316L stainless steel screen, it can not only ensure the screening accuracy, but also extend the life of the screen. It is suitable for the fine processing of ultrafine powders in the fields of electronics and aviation.

What are the advantages of Vibro Sifter Metal Powder?

Vibro Sifter Metal Powder has many advantages, such as high screening efficiency, which can complete the classification of a large amount of metal powder in a short time, and the classification efficiency is 30% higher than that of a traditional single screen machine; convenient operation, different metal powders have different vibration parameter requirements, it supports frequency 15-50Hz variable frequency adjustment, and can match the screening requirements of various powders without changing equipment; corrosion resistance, it uses 304/316L stainless steel screen + surface polishing process, and its rust resistance is more than 5 times that of ordinary screen machines; easy to clean, the screen surface cleaning device can automatically clean the residual powder, reducing the trouble of manual cleaning, and is more worry-free than equipment without self-cleaning function.

Technical parameters of Vibro Sifter Metal Powder

Linear vibrating screen

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Vibro Sifter

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Ultrasonic vibrating screen

| Model |

Screen Diameter (mm) |

Sieving Area (m2) |

Screen Size (mesh) |

Layers |

Power (KW) |

| DHC-400 | 340 | 0.091 | 80-600 | 1~3 | 0.18 |

| DHC-600 | 540 | 0.229 | 0.25 | ||

| DHC-800 | 730 | 0.418 | 0.55 | ||

| DHC-1000 | 900 | 0.636 | 0.75 | ||

| DHC-1200 | 1100 | 0.95 | 1.1 | ||

| DHC-1500 | 1400 | 1.539 | 1.5 | ||

| DHC-1800 | 1700 | 2.269 | 2.2 | ||

| DHC-2000 | 1886 | 2.792 | 2.2 |

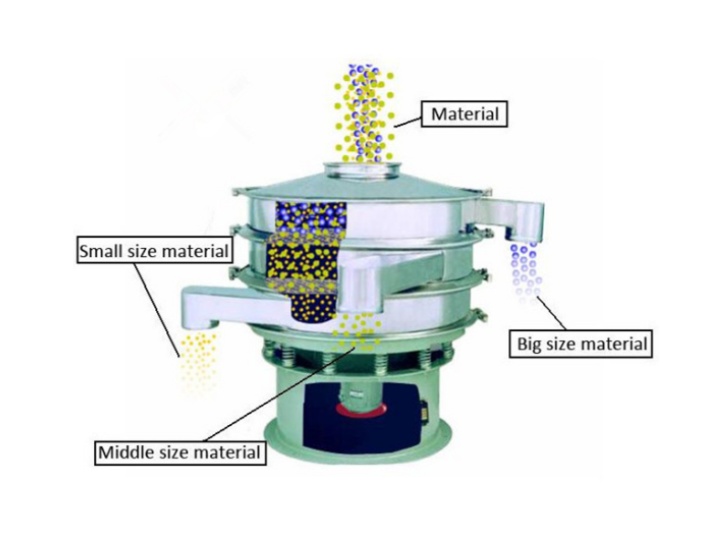

What is the working principle of Vibro Sifter Metal Powder?

The working principle of Vibro Sifter Metal Powder is that the vibration motor drives the screen body to generate high-frequency composite vibration. After this vibration is transmitted to the screen body, it causes the screen surface to form a regular throwing and sliding motion trajectory. In this process, fine particles are more likely to be "thrown up" by vibration due to their light weight and small inertia, and slide along the screen surface under the action of gravity, and finally pass through the sieve holes of the corresponding mesh number to complete the classification; while coarse particles are more likely to "slide" along the screen surface and move toward the outlet due to their large weight and sufficient inertia, thereby achieving coarse and fine separation.

What are the applications of Vibro Sifter Metal Powder?

Vibro Sifter Metal Powder is used in many fields. For example, in the field of powder metallurgy, it can screen iron powder and copper powder to ensure uniform density of pressed parts and reduce internal pores and cracks; in the 3D printing industry, it can finely screen titanium alloy powder and aluminum alloy powder to ensure close bonding between printed layers; in the field of chemical catalysis, it can classify metal catalyst powders to improve reaction efficiency; in the electronics manufacturing industry, it is used to screen silver powder and nickel powder to improve the stability of conductive slurry; in the production of automotive parts, it can screen wear-resistant metal powders to optimize the performance of parts such as brake pads; in the aerospace field, it can screen high-temperature alloy powders to ensure that the quality of key parts such as engine blades meets standards.

As a key equipment for metal powder processing, Vibro Sifter Metal Powder accurately adapts to different screening requirements from coarse particles to ultrafine powders through targeted machine selection (such as linear vibrating screen, rotary vibrating screen, ultrasonic vibrating screen), taking into account the characteristics of metal powder (such as magnetism, corrosiveness, agglomeration), and relying on its high screening efficiency and accurate classification advantages, it plays an irreplaceable role in powder metallurgy, 3D printing, aerospace and other fields. It not only realizes the accurate classification and purification of metal powder, but also provides solid support for efficient production and technological upgrading of related industries by optimizing production processes and improving product quality.