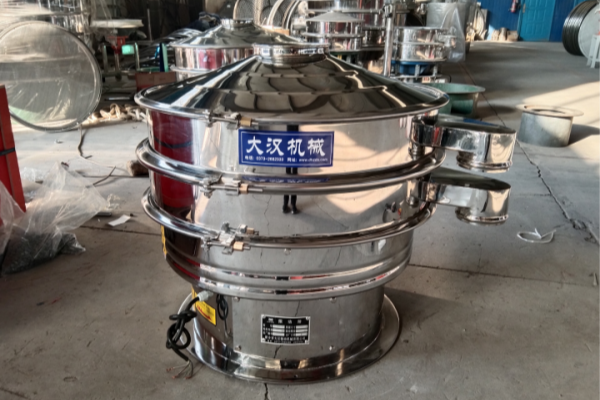

Apatite Vibro Sifter

The price range of Apatite Vibro Sifter is$600 to $5200/Set,ideal for apatite ore sizing and powder classification in mining workflows.

Screen Mesh:2-600 Mesh

Capacity:10Kg-10Tons/hour

layer:1-5 layers

Motor power:2.2-7.5kW

Material:Carbon Steel, Stainless Steel 304/316L

What is Apatite Vibro Sifter?

Apatite Vibro Sifter can process apatite materials of different particle sizes, including coarse particles (greater than 5mm), medium particles (1-5mm) and fine powder (80-400 mesh). According to different particle sizes, you can choose the appropriate model: coarse particles of apatite are suitable for mining vibrating screens, which can efficiently cope with the screening of large-size materials; medium particles can choose linear vibrating screens to achieve smooth transportation and classification; 80-400 mesh fine powder is recommended for rotary vibrating screens, which can reduce agglomeration and blockage with ultrasonic systems. This type of equipment uses wear-resistant and hardened screens, and anti-corrosion seals are made at key parts. It can accurately classify and remove impurities to improve the quality of ore. Apatite Vibro Sifter is often used in phosphate ore beneficiation and waste rock separation, fertilizer production grading apatite powder, ceramic raw material screening and impurity removal, etc. It has strong adaptability and high screening efficiency.

Apatite has the characteristics of high hardness and corrosiveness. Among them, fine powder of 80-400 mesh is also prone to agglomeration due to moisture or static electricity. Based on these properties, it is recommended to select the machine model according to the particle size of the material. For coarse particles, due to their high hardness, it is recommended to use a mining vibrating screen; for medium particles, both transportation and corrosion protection must be taken into account, and the sealing design of the linear vibrating screen is more suitable; fine powders are prone to agglomeration, and the ultrasonic function of the rotary vibrating screen can effectively break up the agglomerated powders, reduce clogging, and ensure smooth screening.

How to classify and select Apatite Vibro Sifter?

Rotary vibrating screen: specially designed for 80-400 mesh apatite fine powder, using multi-layer screens (2-600 mesh optional) + ultrasonic system. High-frequency vibration disperses fine powder, and ultrasonic waves disperse sticky clumps, solving the problem of easy clogging of wet-based apatite (water content 8%-15%), which is suitable for fine scenes such as fertilizer powder classification and ceramic glaze impurity removal.

Linear vibrating screen: suitable for 1-5mm medium-particle apatite, conveying materials in a straight track, and dual motors synchronously vibrating to stabilize the screen surface. The processing capacity is 5-15 tons/hour, which is suitable for continuous production lines such as primary screening of phosphate ore dressing and recovery of phosphogypsum, taking into account both classification efficiency and material uniformity.

Mining vibrating screen: designed for coarse apatite particles above 5mm, with a sturdy body and a screen made of highly wear-resistant material. It can quickly push coarse particles with large amplitude and low frequency vibration, and can withstand the impact of impurities such as quartz and shale. It is used for coarse screening of phosphate ore (separation of waste rock and concentrate).

What are the advantages of Apatite Vibro Sifter?

The core advantage of Apatite Vibro Sifter lies in its screening efficiency. Its screening efficiency far exceeds that of conventional equipment. It can handle a large amount of materials and achieve accurate particle size classification. The multi-layer screen surface design can simultaneously complete the separation of 6 materials with different particle sizes, greatly improving the classification efficiency. The main body of the equipment is made of 304 or 316L stainless steel, which has strong corrosion resistance and meets the strict requirements of food, medicine and other industries for hygiene standards. Compared with similar equipment, its maintenance is simple and cost-controlled, and key components are durable and easy to replace. The fully enclosed structure effectively prevents dust from spilling and ensures a safe working environment. Low noise and low energy consumption during operation can further reduce operating costs (annual maintenance costs are reduced by 50% compared with traditional equipment).

Technical parameters of Apatite Vibro Sifter

Rotary vibrating screen

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

Linear vibrating screen

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

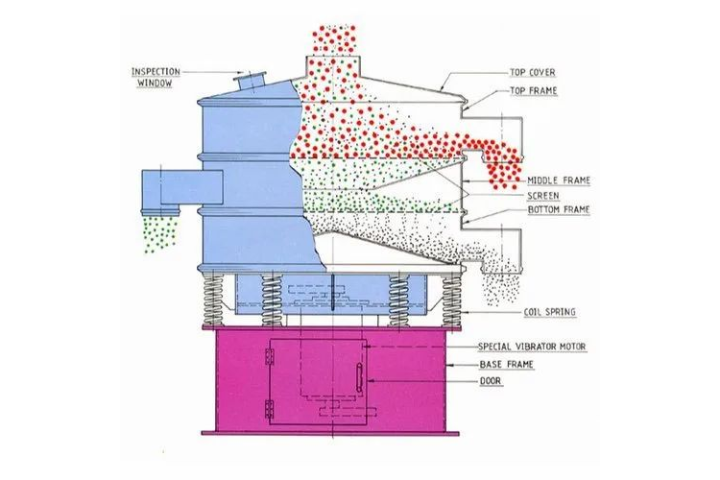

What is the working principle of Apatite Vibro Sifter?

The working principle of Apatite Vibro Sifter is to drive the screen body to generate high-frequency vibration through a vibration motor, and cooperate with the ultrasonic system to operate. The vibration motor drives the eccentric structure to rotate and generate centrifugal force, so that the screen box forms a compound movement combining horizontal shaking, vertical vibration and spiral propulsion, and the ultrasonic device transmits high-frequency vibration to the screen, quickly breaking up the powder agglomerates formed by moisture or static electricity, and preventing fine powder from clogging the mesh. Under the dual action, apatite particles of different particle sizes are separated according to the mesh aperture, and qualified materials are discharged through the mesh to achieve accurate screening.

What are the applications of Apatite Vibro Sifter?

Apatite Vibro Sifter is widely used and can accurately adapt to the screening needs of apatite in many fields. In phosphate ore dressing, multi-level screening can be used to quickly separate apatite concentrate from large waste rocks, reducing the waste of raw materials in subsequent processing; in fertilizer production, the particle size of apatite powder can be controlled (such as 80-200 mesh) to ensure the uniform release of nutrients in compound fertilizers and avoid fertilizer loss or agglomeration; in the ceramic industry, fine powder (<0.1mm) can be graded and impurities such as siliceous rock can be removed to improve the gloss and quality stability of the glaze; in the field of environmental protection, recyclable particles can be separated from impurities through screening, and impurities (such as clay, sand and gravel) can be screened and removed in the comprehensive utilization of phosphogypsum to help the production of environmentally friendly building materials.

As a special equipment for apatite screening, Apatite Vibro Sifter has become a key equipment in the phosphate ore processing process with its customized design and stable and reliable operation performance. It is deeply optimized for the physical properties of apatite, and can accurately screen apatite particles in multiple particle size ranges such as 80-400 mesh. The processing capacity of a single device covers 1 to 15 tons per hour, and it can flexibly adapt to the diverse needs from small-scale production to large-scale processing. In the process of improving the purity of phosphate concentrate, ensuring the quality of raw materials for fertilizer production, or promoting the efficient recycling of solid wastes such as phosphogypsum, its stable screening ability has always provided strong support for the effective utilization of apatite resources - it not only reduces the loss during the processing process, but also continuously improves the production efficiency of various application scenarios.