Vibrating Sieve for Powder

The price of vibrating sieve for powder is $600 to $5000 per set, which can solve the screening problems of sticky/easy to block/ultra-light powders.

Price:$600.00-$5,000.00/Set

Screen Mesh:2-500 Mesh

Capacity:1-5Tons/hour

layer:1-6 layers

Material:Carbon Steel, Stainless Steel 304/316L,plastic.

What is a vibrating sieve for powder?

The Vibrating Sieve for Powder is a device for powder classification and impurity removal. Its screening mesh can reach up to 500 meshes, and its processing capacity can reach up to 5000kg per hour. The screen specifications and materials (such as food-grade stainless steel, plastic, carbon steel, etc.) can be customized on demand, perfectly adapting to the needs of different industries. At present, this equipment has been widely used in the food industry (flour particle size control, milk powder agglomeration filtration), pharmaceutical manufacturing (raw material purification, auxiliary material impurity removal), and chemical industry (coating powder classification, additive screening), among other fields. It can not only greatly improve the screening efficiency but also effectively enhance the powder purity, making it an important piece of equipment in the powder processing link.

What types of vibrating sieve for powder are there?

Vibrating sieves for powder usually include rotary vibrating screens, linear vibrating screens, ultrasonic vibrating screens, and swing screens. Each type has different adaptable materials and screening advantages.

Rotary vibrating screen: It has high screening accuracy (can screen 100-500 mesh fine powder) and is suitable for fine powders, such as flour, milk powder, chemical raw materials, etc.

Linear vibrating screen: It features high screening efficiency, large processing capacity, and easy screen replacement. It is suitable for medium-coarse powders or powders with good fluidity, such as sand, feed, and fertilizer.

Ultrasonic vibrating screen: It can solve the problem of screen blocking, with higher screening accuracy than ordinary rotary vibrating screens. It is suitable for extremely fine or easy-to-stick powders, such as pharmaceutical intermediates and lithium battery materials.

Airflow screen: It is used to screen powders with almost no blockage, suitable for extremely fine, light, or easy-to-raise-dust powders (e.g., starch, coffee powder, Chinese medicine powder).

Swing screen: It causes minimal damage to powders, extends screen life, and is suitable for powders that are easy to break or require gentle screening (e.g., milk powder, coffee beans, spices).

What materials are vibrating sieve for powder made of?

The material selection of Vibrating Sieve for Powder mainly depends on the material characteristics, usage scenarios, and cost budget. Common materials include 304 stainless steel, 316L stainless steel, carbon steel, and plastic.

304 stainless steel: Strong corrosion resistance, easy to clean, meets food/medical hygiene requirements, high strength, and long service life. Suitable for most powders (e.g., salt, Chinese medicine powder), though its cost is 30%-50% higher than carbon steel.

316L stainless steel: Molybdenum is added to 304 stainless steel, enhancing corrosion resistance (e.g., for strong acid/alkaline materials) and high-temperature resistance (up to 800℃), with even higher hygiene standards. Its cost exceeds that of 304 stainless steel by over 50%.

Carbon steel: Low cost, high strength, good toughness, but prone to rust, requiring additional anti-corrosion treatment. Suitable for scenarios with budget constraints and low hygiene requirements (e.g., screening ore and alloy powder).

Plastic: Lightweight, acid/alkali-resistant (especially PP/PE), low cost; however, poor temperature resistance (generally ≤80℃), low strength, and prone to aging. Suitable for laboratory or small-scale chemical liquid screening.

What are the advantages of using a vibrating sieve for powder?

Vibrating Sieves for Powder offer multiple advantages, including high screening efficiency, precise grading, strong adaptability, simple maintenance, and low operational difficulty, which can boost production efficiency and product quality.

High screening efficiency: Suitable for large-scale production, preventing material accumulation and blockage, with processing capacity far exceeding manual operations.

High grading accuracy: Meets fine-screening needs, capable of precisely processing powders as fine as 500 mesh. It strictly separates coarse and fine particles using screens of varying mesh sizes.

Strong adaptability: Compatible with diverse powder characteristics. Different Vibrating Sieve models address challenging screening scenarios (e.g., stickiness, fragility, ultra-lightness).

Simple maintenance: With a straightforward structure, low maintenance costs, and easy cleaning, it significantly reduces upkeep expenses.

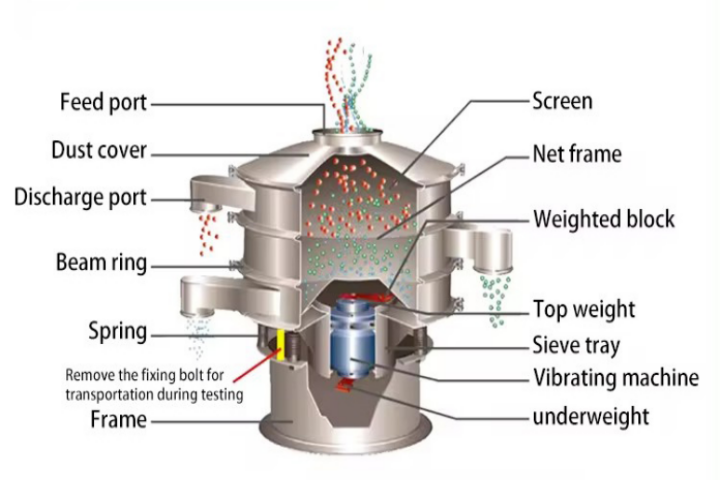

What is the working principle of the vibrating sieve for powder?

The vibrating sieve for powder relies on centrifugal force generated by vibration motors to drive materials onto the screen surface, where they undergo a throwing motion. By leveraging differences in powder particle size, fine particles pass through the screen and fall to the outlet below, while coarse particles or impurities are separated, achieving accurate grading and impurity removal. Different types of vibrating sieves adapt to powder characteristics by adjusting vibration direction, frequency, amplitude, and other parameters.

What scenarios are Vibrating Sieves for Powder suitable for?

Vibrating Sieves for Powder are commonly used in food processing, pharmaceutical manufacturing, building materials, new energy materials, cosmetics production, and other fields to achieve precise classification, impurity removal, or purification of powders.

Food processing: Screening from raw materials to finished products (e.g., flour bran removal, milk powder de-caking, coffee powder classification) not only removes impurities but also ensures uniform particle size, enhancing the final product’s taste and stability.

Pharmaceutical manufacturing: When processing raw material powders or Chinese medicine ultrafine powders, it is essential to remove foreign matter while complying with GMP and other hygiene standards, ensuring powder purity and uniformity to lay the groundwork for subsequent formulation production.

Building materials: Screening cement powder, ceramic body powder, etc., by controlling particle coarseness to adapt to formulas with varying strength requirements (e.g., high-strength concrete requires removing coarse particles to ensure material performance stability).

New energy materials: For lithium battery cathode materials, semiconductor silicon powder, etc., it achieves nano-level precision screening, reducing the impact of impurities on electrode conductivity and chip performance—a critical step in producing high-purity materials.

Cosmetics production: In processing talcum powder and foundation raw materials, fine screening removes particle agglomerates, creating smooth, "skin-melting" powders that enhance product texture.

The vibrating sieve for powder produced by our factory boasts multiple advantages. It not only delivers high screening efficiency but also enables precise control over powder grading accuracy via adjustable vibration parameters. Additionally, its compatibility with diverse powder characteristics (through varied screen types), low daily maintenance costs, and ease of operation make it a versatile solution. From material (304/316L stainless steel, carbon steel, plastic) and mesh count (2-500mesh) to screen layers (1-6 layers) and screening frequency (50-500Hz), all configurations support personalized customization to precisely match your needs. Feel free to contact us if you require tailored solutions.