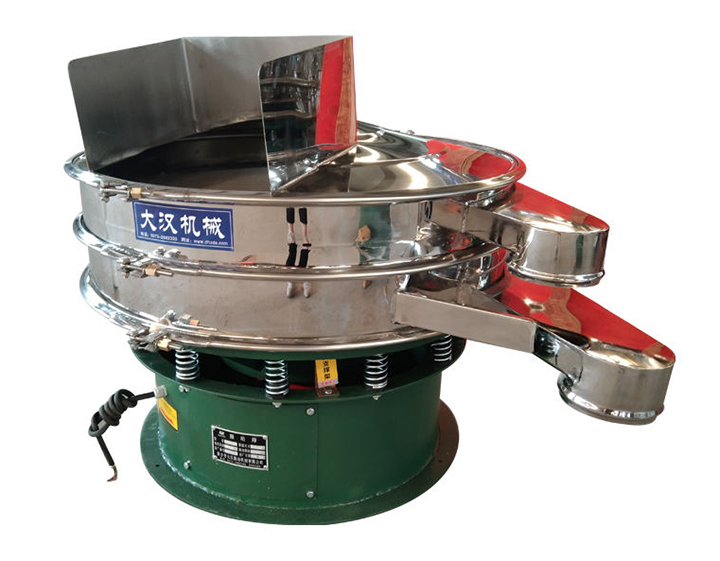

Swing Vibrating Screen

The price of the Swing Vibrating Screen is $800to $3800/Set,suitable for sieving viscous or easily clogging materials.

Diameter:600-2600mm

Screen Mesh:20 microns - 20 mm

layer:1-5 layers

Noise Level:less than 80dB

Material:Carbon Steel, Stainless Steel 304/316L,plastic.

What is Swing Vibrating Screen?

Swing Vibrating Screen is a common screening equipment. Its working core lies in that when the motor drives the eccentric wheel to rotate, the screen box will swing back and forth and vibrate up and down at the same time, so as to separate the coarse and fine materials, and also break up the sticky materials, which are not easy to clog the screen. Therefore, it is suitable for scenes with high screening accuracy requirements, high viscosity and easy clogging of materials, such as processing wet sand, flour, coatings, etc. Compared with ordinary vibrating screens, it has lower noise during operation, gentler screening process, can reduce material loss, and more convenient cleaning and maintenance. It is a screening tool that takes into account both efficiency and practicality.

What materials are Swing Vibrating Screen made of?

The materials of swing vibrating screens mainly include stainless steel, carbon steel and plastic. Different materials have different focuses in terms of strength, corrosion resistance, applicable environment, etc., providing a variety of options for the functional adaptation of screening equipment.

304/316 stainless steel: 304 stainless steel is suitable for scenes with high hygiene requirements such as food (flour, condiments), medicine (raw material powder), etc., to avoid contamination caused by reaction between materials and metals; 316 stainless steel contains molybdenum, is resistant to strong acids and alkalis, and is often used in chemical industry (paint slurry, acid and alkali solution filtration) or humid and highly corrosive environments (such as ore screening in coastal areas). Its surface is smooth and easy to clean, which can reduce material residue and meet strict hygiene standards.

Carbon steel: It is the most basic material with low cost and easy to rust. It is mostly used in dry and non-corrosive rough operation scenes (coarse and fine separation of crushed stone, screening of ceramic powder). It needs to be sprayed with paint regularly to extend its life. Although it has average rust resistance, it can still operate stably in most environments and has a high cost-effectiveness.

Plastic (PVC): This model adopts a lightweight design with both anti-static and chemical corrosion resistance. It can be used to screen electronic materials and other materials that are easily contaminated by metals. It has good toughness, can reduce hard friction with materials, and avoid particle damage, but its load-bearing capacity is weak and it is not suitable for heavy screening scenes.

What are the advantages of using Swing Vibrating Screen?

The advantages of Swing Vibrating Screen are significant. The screening efficiency is significantly improved compared with traditional equipment, and it can quickly complete material classification; it has high precision and can accurately separate particles of different sizes; it has strong anti-blocking properties, reduces material jams, and reduces the frequency of cleaning; it has a wide range of applications, from sticky materials to hard particles; it has little damage to the material and can retain the complete shape of the particles; it has low operating noise, which is conducive to improving the workshop environment; the structural design is easy to clean and maintain, saving labor costs; the material adaptability is flexible, and durable materials can be selected according to the scene to extend the life of the equipment.

What are the technical parameters of Swing Vibrating Screen?

| Model | YB600 | YB1000 | YB1200 | YB1600 | YB2000 | YB2600 |

| Diameter. | 650 mm | 1040 mm | 1250 mm | 1580 mm | 1880 mm | 2650 mm |

| Screening area | 0.29M2 | 0.76 M2 | 1.1 M2 | 1.8 M2 | 2.6 M2 | 5.3 M2 |

| space requirement | 0.4 M2 | 1.8 M2 | 2.5 M2 | 3.9 M2 | 5.6 M2 | 9.6 M2 |

| Layers | 1-5 | |||||

| Power | 0.25 KW | 1.5 KW | 2.2 KW | 3.0 KW | 4.0 KW | 5.5 KW |

| Machine base | 630 mm | 900 mm | 1100 mm | 1340 mm | 1340 mm | 1940 mm |

| Height of 1 layer | 830 mm | 1155 mm | 1480 mm | 1480 mm | 1500 mm | 1580 mm |

| Weight of 1layer | 140 KG | 490 KG | 700 KG | 980 KG | 1050 KG | 1900 KG |

| Height of 2 layers | 965 mm | 1280 mm | 1640 mm | 1640 mm | 1660 mm | 1710 mm |

| Weight of 2 layers | 155 KG | 535 KG | 770 KG | 1060 KG | 1140 KG | 2000 KG |

| Height of 3 layers | 1080 mm | 1400 mm | 1800 mm | 1800 mm | 1820 mm | 1840 mm |

| Weight of 3 layers | 170 KG | 580 KG | 840 KG | 1140 KG | 1230 KG | 2100 KG |

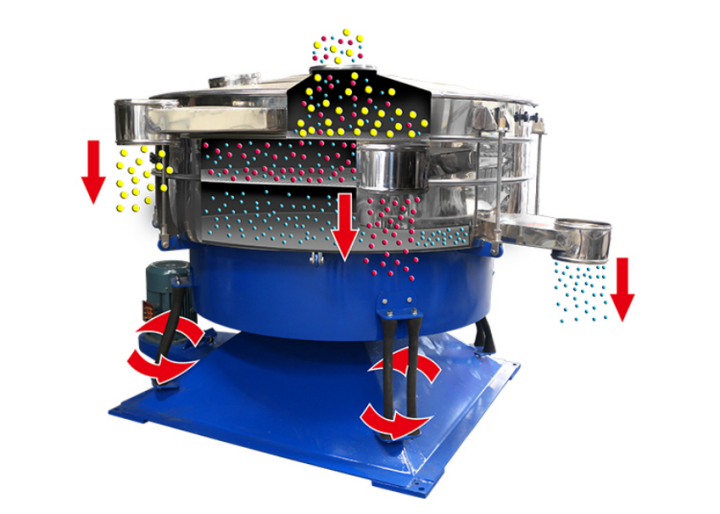

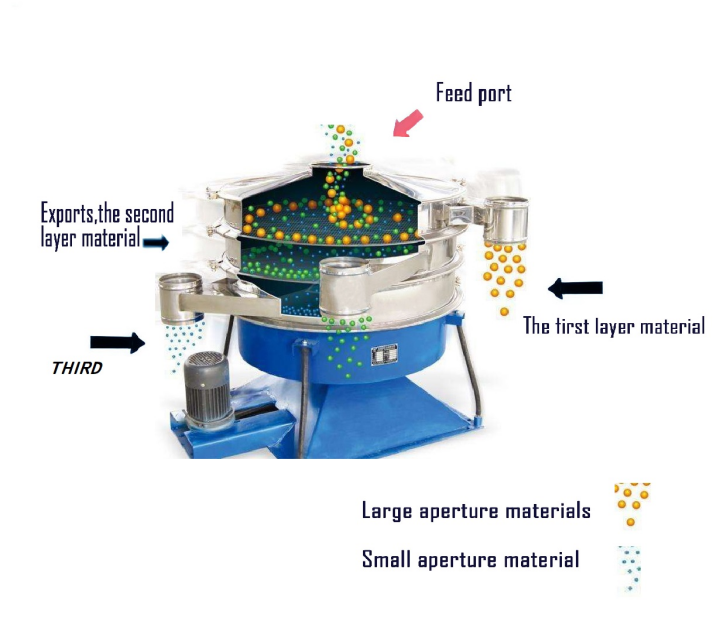

How does the Swing Vibrating Screen work?

The operation of the swing vibrating screen can be summarized as a continuous process of "motor drive-eccentric wheel force-compound motion screening": after the motor is started, it drives the eccentric wheel to rotate at high speed to generate centrifugal force. This force drives the screen box to complete two actions at the same time: swinging back and forth and vibrating up and down, forming a unique motion trajectory of "shaking and pushing". This movement causes wet and sticky mud, easy-to-clump flour or entangled fibers to be vibrated and dispersed, and no longer stick together; then, the material moves forward with the swing of the screen box, and large particles cannot pass through the pores of the screen and are left on the screen, while small particles leak from the mesh along the screen surface to the bottom, completing the classification of coarse and fine particles.

What does the structure of the Swing Vibrating Screen include?

The Swing Vibrating Screen is mainly composed of a screen box, a screen, a drive system, and supporting components.

Screen box: the main frame of the equipment, mostly made of 304/316 stainless steel (food, chemical scene) or plastic.

Screen: the core screening component, the material is adjusted according to the material characteristics (stainless steel, plastic)

Drive system: composed of motor, eccentric wheel and transmission belt, the motor provides power, and the eccentric wheel rotates to generate periodic force.

Support components: including base and shock pad, used to stabilize the equipment and reduce the impact of vibration on the ground

What are the applications of Swing Vibrating Screen?

Swing vibrating screen can handle flour, condiments, ore, wet sand, sand and gravel aggregate, concrete raw materials, paint slurry, solid waste, pharmaceutical raw materials, Chinese medicine powder and other materials, and can achieve classification, dehydration, processing, filtering, screening and other operations. Its application involves food processing, mining, building materials, chemical environmental protection, medicine and other industries, and can play an efficient screening role in material processing in various fields.

Swing Vibrating Screen customer cases

In industrial screening scenarios, swing vibrating screen is a practical equipment to solve the problems of sticking and precision. The screen box material of our Swing Vibrating Screen can be carbon steel (conventional), 304/316 stainless steel (food/chemical), plastic (corrosion resistant), and the screen mesh can be matched as needed (metal mesh, nylon mesh, etc.) to reduce clogging; the vibration frequency and amplitude are stable, and daily maintenance only requires the replacement of wearing parts, which is easy to operate. The manufacturer should be selected according to your material (wet material, fine powder or hard material) and production line requirements. We have been focusing on screening equipment for many years, and can adjust the equipment details (such as screen surface inclination, vibration parameters) according to your production capacity and site to provide a more suitable solution. If customization is required, please feel free to communicate.