Circular Vibrating Sieve Manufacturer

Saturday July-12 2025 12:39:01

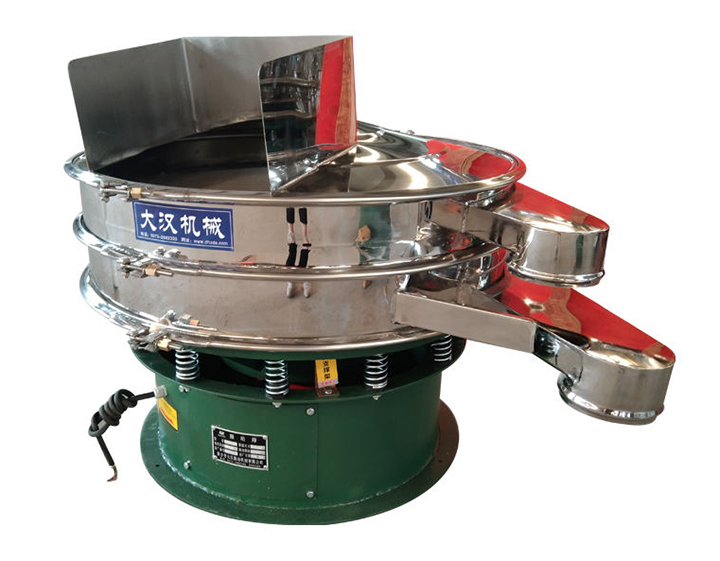

In the field of industrial screening equipment, the quality and performance of Circular Vibrating Sieve directly affect production efficiency and product quality, so choosing a reliable manufacturer is crucial. As a professional manufacturer of Circular Vibrating Sieve, our factory, relying on years of technical accumulation and production experience, is committed to providing high - quality screening equipment for various industries. Our products not only perform excellently in terms of performance, but also can provide appropriate solutions according to customer needs, thus winning a good reputation in the market.

What are the characteristics of our factory's Circular Vibrating Sieve?

The Circular Vibrating Sieve produced by our factory has stable and reliable performance, and can efficiently complete the screening work of 2 - 500mesh (850μm - 30μm). Its screening efficiency can reach more than 95%, which can effectively ensure the accuracy and consistency of material screening. The equipment is made of high - quality SUS316L stainless steel or high - strength carbon steel, with a service life of 8 - 10 years, reducing the cost of frequent equipment replacement. The vibration frequency can be adjusted between 30 - 60Hz, and the amplitude range is 1 - 5mm, which can meet the screening needs of materials with different physical properties. At the same time, the anti - blocking device equipped with the equipment can reduce the blocking rate by more than 90%, ensuring the continuous and stable screening process. In view of the special needs of different customers, we can provide customized services, including adjusting the screen mesh range, equipment size, material and whether to install a frequency conversion device, so as to meet the screening requirements of different scenarios.

What are the advantages of Circular Vibrating Sieve?

Circular Vibrating Sieve has significant advantages in many aspects. Firstly, it has high screening accuracy, which can accurately separate materials of different particle sizes within the range of 2 - 500mesh, meeting the needs of fine production. Secondly, it has strong durability. Made of high - quality materials, it has a solid structure, can withstand long - term and high - intensity work, and has low maintenance costs. Thirdly, it has wide adaptability. It can handle various materials such as powders, granules and viscous materials by adjusting the vibration frequency and amplitude. Fourthly, it has good safety. It is equipped with perfect safety protection devices, such as screen frame locking mechanism and overload protection system, to ensure the safety of operators.

Which industries is Circular Vibrating Sieve suitable for?

Circular Vibrating Sieve plays an important role in many industries. In the food industry, it can be used for the screening and classification of materials such as flour, sugar and spices to ensure product purity; in the chemical industry, it can process catalysts, pigments, etc., contributing to chemical synthesis and material processing; in the mining field, it can classify the particle size of mineral powders, metal abrasives, etc., assisting in ore processing; in the pharmaceutical industry, it is used to screen active pharmaceutical ingredients and excipients to ensure material uniformity and meet GMP standards; in the coating and ink industry, it can filter impurities in pigments and fillers to ensure product quality.

Choosing a suitable manufacturer of Circular Vibrating Sieve is the key to ensuring the quality of the equipment and the subsequent use effect. Our factory has always attached importance to product quality and customer needs. The Circular Vibrating Sieve produced by us performs excellently in the screening range of 2 - 500mesh, with stable and reliable performance parameters, and can also provide customized services. With the many advantages of the equipment and its wide application in various industries, we are confident to provide customers with satisfactory screening equipment, helping them improve production efficiency and product quality, and achieve win - win development.

Circular Vibrating Sieve

Circular Vibrating Sieve