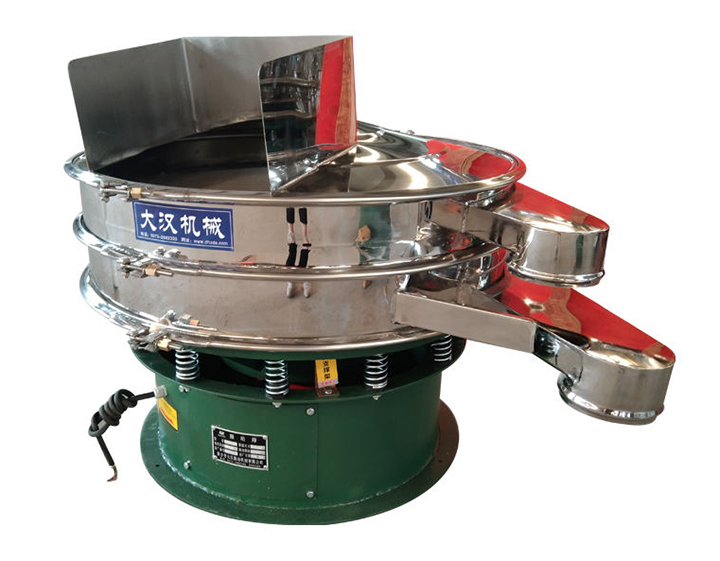

Circular Vibrating Sieve

Circular Vibrating Sieve is priced at $600.00 and $4,000.00 per set.. A variety of models are offered, usually categorized by screening mesh (for instance 2-80 mesh, 60-300 mesh, 250-500 mesh) and processing capacity.

Price$600.00 - $4,000.00

Mesh size: 2-500 mesh

Capacity: 100-3000kg/h

Layer(s): 1-5layers

Material:Stainless steel 304,316L,or Carbon Steel

Model: Ø 400- Ø 2000 mm

What is a Circular Vibrating Sieve?

The Circular Vibrating Sieve is a high-performance screening device, specially designed for precise particle size separation and classification of powders, granules and viscous materials. Its key feature is a cylindrical stainless steel or carbon steel body paired with an eccentric vibration drive system, generating circular vibrations for uniform material screening. Unlike linear vibrating screens, its 360° circular vibration trajectory enhances material flow and reduces screen clogging. Suitable for 20-500 mesh (850μm-30μm) screening, it is widely used in food, chemical, mining and other industries.

What Are the Types of Circular Vibrating Sieves?

Circular vibrating sieves have diverse types to meet specific application needs, each with unique features to adapt to different materials and working conditions.

Circular Vibratory Sifter:Basic type with classic circular vibration trajectory. Ideal for general powder/granule screening, balancing efficiency and cost-effectiveness in routine industrial use.

Ultrasonic Vibrating Screen:Equipped with ultrasonic system to tackle fine, adhesive materials. Emits high-frequency waves to prevent mesh blinding, ensuring stable sieving of micro-powders (down to 20μm).

Direct Discharge Sifter:Optimized for high-throughput, single-stage screening. Simplified structure for quick material discharge, commonly used in bulk material preliminary filtration.

Filter Screen:Specialized for liquid-solid separation. Fine mesh with reinforced structure handles viscous fluids, widely applied in beverage, chemical slurry filtration.

High Frequency Vibrating Screen:Utilizes high-frequency, low-amplitude vibration. Enhances separation precision for ultra-fine particles (≤30μm), critical in pharmaceutical, advanced material industries.

Circular Vibrating Sieve has performed well in screening operations in various industries with its many advantages. It is not only cost-effective, but also has flexible adaptability while taking into account safety performance.

High Cost-Effectiveness: With a long service life due to robust construction materials, the circular vibrating sieve reduces the need for frequent replacements. Its energy-efficient design also cuts down on operational costs, making it a cost-effective choice for long-term use.

Flexible Adaptability: The adjustable vibration frequency and amplitude allow it to handle a wide variety of materials with different physical properties. Additionally, the modular design enables quick replacement of screen layers, facilitating seamless transitions between different screening tasks.

Enhanced Safety: Integrated safety features, such as secure locking mechanisms for screen frames and overload protection for the vibration drive system, ensure operator safety during operation and maintenance. Dust-proof and anti-static designs also contribute to a safer working environment.

Easy Integration: Its standardized interfaces and customizable inlets/outlets enable effortless integration into existing production lines, streamlining the manufacturing process and improving overall productivity.

Circular vibrating sieves utilize circular vibration to drive material movement, combining multi-stage sieving and anti-clogging features for efficient particle separation. These sieves are widely used in industries such as mining, construction, and food processing.

Vibration-driven Material Movement: Eccentric motor rotation forms a spiral trajectory of materials on the screen surface. Fine particles pass through the mesh while coarse particles discharge along the periphery.

Multi-stage Classification: Materials undergo layer-by-layer sieving from top to bottom, with each screen retaining corresponding particle sizes until precise classification is completed.

Anti-clogging Solutions: Optional ultrasonic systems or rubber ball cleaners prevent adhesive materials from blinding screens.

Intelligent Control: PLC controller monitors vibration parameters and sieving time in real-time. Touchscreen supports operation and data logging.

Parameter

Circular Vibratory Sifter:Basic type with classic circular vibration trajectory. Ideal for general powder/granule screening, balancing efficiency and cost-effectiveness in routine industrial use.

Ultrasonic Vibrating Screen:Equipped with ultrasonic system to tackle fine, adhesive materials. Emits high-frequency waves to prevent mesh blinding, ensuring stable sieving of micro-powders (down to 20μm).

Direct Discharge Sifter:Optimized for high-throughput, single-stage screening. Simplified structure for quick material discharge, commonly used in bulk material preliminary filtration.

Filter Screen:Specialized for liquid-solid separation. Fine mesh with reinforced structure handles viscous fluids, widely applied in beverage, chemical slurry filtration.

High Frequency Vibrating Screen:Utilizes high-frequency, low-amplitude vibration. Enhances separation precision for ultra-fine particles (≤30μm), critical in pharmaceutical, advanced material industries.

What Are the Advantages of Circular Vibrating Sieve?

Circular Vibrating Sieve has performed well in screening operations in various industries with its many advantages. It is not only cost-effective, but also has flexible adaptability while taking into account safety performance.

High Cost-Effectiveness: With a long service life due to robust construction materials, the circular vibrating sieve reduces the need for frequent replacements. Its energy-efficient design also cuts down on operational costs, making it a cost-effective choice for long-term use.

Flexible Adaptability: The adjustable vibration frequency and amplitude allow it to handle a wide variety of materials with different physical properties. Additionally, the modular design enables quick replacement of screen layers, facilitating seamless transitions between different screening tasks.

Enhanced Safety: Integrated safety features, such as secure locking mechanisms for screen frames and overload protection for the vibration drive system, ensure operator safety during operation and maintenance. Dust-proof and anti-static designs also contribute to a safer working environment.

Easy Integration: Its standardized interfaces and customizable inlets/outlets enable effortless integration into existing production lines, streamlining the manufacturing process and improving overall productivity.

How Does a Circular Vibrating Sieve Work?

Circular vibrating sieves utilize circular vibration to drive material movement, combining multi-stage sieving and anti-clogging features for efficient particle separation. These sieves are widely used in industries such as mining, construction, and food processing.

Vibration-driven Material Movement: Eccentric motor rotation forms a spiral trajectory of materials on the screen surface. Fine particles pass through the mesh while coarse particles discharge along the periphery.

Multi-stage Classification: Materials undergo layer-by-layer sieving from top to bottom, with each screen retaining corresponding particle sizes until precise classification is completed.

Anti-clogging Solutions: Optional ultrasonic systems or rubber ball cleaners prevent adhesive materials from blinding screens.

Intelligent Control: PLC controller monitors vibration parameters and sieving time in real-time. Touchscreen supports operation and data logging.

Parameter

| Model |

Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

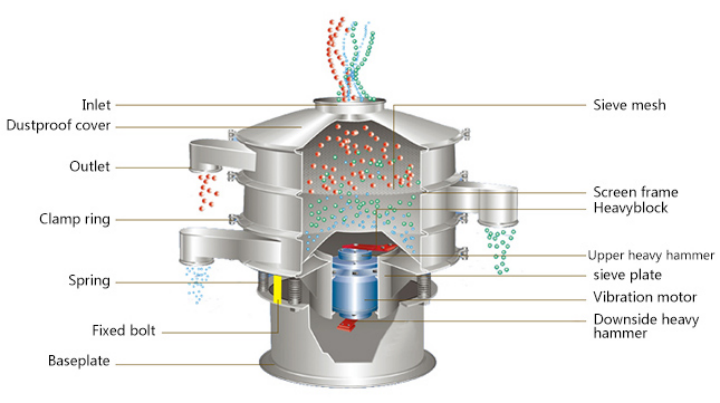

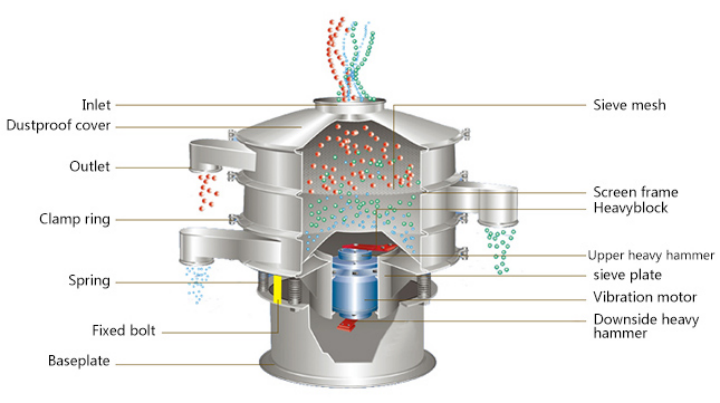

What Is the Structure of Circular Vibrating Sieve?

Cylindrical Screen Body: Composed of stackable stainless steel or carbon steel screen frames. Different screen layers use corresponding materials to accommodate coarse/fine materials. Quick-clamp rings facilitate disassembly and sealing.

Vibration Drive System: Eccentric vibration motor with adjustable counterweights generates circular vibration. Frequency conversion devices can be optionally equipped to adapt to different material characteristics.

Dust-proof & Sanitary Design: Sealing gaskets and anti-static coatings prevent dust leakage. Mirror-polished surfaces meet sanitary standards. Detachable components enable easy cleaning.

Support & Adjustment Mechanism: Spring-supported base absorbs vibration. Adjustable feet ensure equipment stability. Customizable inlet/outlet chutes adapt to automated production lines.

Where Is a Circular Vibrating Sieve Applied?

With its multi-functional design, the equipment serves critical roles in quality control and production across industries for material screening, classification, and filtration.Food & Beverage: Sieving and classification of flour, sugar, spices; pulp separation and suspension filtration.

Chemicals & Plastics: Suitable for catalysts, pigments, plastic pellets; supports chemical synthesis and material processing.

Mining & Metallurgy: Particle size classification of mineral powders, metal abrasives, and refractory materials; assists ore processing.

Pharmaceutical Industry: Sieving active pharmaceutical ingredients (APIs) and excipients to ensure material uniformity and meet GMP standards.

Coatings & Inks: Filtering pigments and fillers; eliminating agglomerates to guarantee coating quality and application performance.

What Is the Price Range of Circular Vibrating Sieve?

The price of Circular Vibrating Sieve varies depending on factors such as model, material, size, and additional functions, generally ranging from $600.00 and $4,000.00 per set. For basic models like the standard Circular Vibratory Sifter with a small screen area and simple configuration, the price is relatively low, around $600.00 -$1,500.00. Models with larger screen sizes, made of high-quality stainless steel, and equipped with advanced features such as frequency conversion devices or ultrasonic systems, such as the Ultrasonic Vibrating Screen or High Frequency Vibrating Screen, usually have higher prices, ranging from $2,000.00 -$4,000.00 In addition, customized Circular Vibrating Sieves designed according to specific industry needs, such as those meeting strict sanitary standards for the food and pharmaceutical industries, may also have higher prices due to the special processing and materials required.