Chemical Materials Coarse Crusher

It is a coarse crusher used to crush hard, fibrous chemical raw materials of different types, achieving the crushed particle size by reducing the volume of the chemical raw materials.

Price: $800-$9,800

Grinding particle size: 0.5-20mm

Output: 50-5000kg/h

Feed particle size: 200mm

What is Chemical Materials Coarse Crusher?

Chemical Materials Coarse Crusher is a coarse crusher used in the chemical industry for crushing chemical raw materials. It features a vertical crushing structure and can efficiently process chemical raw materials of various hardness and viscosity. It can crush chemical raw materials to a particle size of 0.5-20 mm, providing pretreatment for subsequent fine grinding or processing. It is suitable for crushing various chemical raw materials of different hardness, brittleness, fibrousness, and toughness, including solid chemicals, plastic granules, and resin materials.

The Chemical Materials Coarse Crusher can be used to crush chemical raw materials of different sizes from 50mm to 1500mm. The crushed chemical raw materials are generally coarse, with a particle size of 0.5-125mm. Some models can reach a fine particle size of 5mm, which can provide raw materials for subsequent processing and direct use. The crushed material particles are uniform without over-crushing and are not affected by the viscosity and hardness of the material. The crushing capacity is 50-5000 kg per hour.

What are the advantages of Chemical Materials Coarse Crusher?

The Chemical Materials Coarse Crusher boasts high crushing efficiency, enabling rapid processing of large quantities of materials. It can coarsely crush chemical raw materials of various hardnesses and fibers, producing uniform particle size and low dust content. Made of high-strength wear-resistant materials, it features built-in overload protection, making it robust, durable, and easy to maintain.

Efficient crushing: It adopts a vertical crushing mechanism, which is not limited by the viscosity and hardness of the material, and can achieve ideal crushing effect for any chemical raw material.

Controllable particle size: By replacing the screen, the discharge particle size can be accurately controlled within the range of 0.5-20mm (10-40 mesh)

Safe and reliable: equipped with overload protection device and power interlocking protection system, and the pulley is equipped with a protective cover

Wide applicability: not limited by material viscosity, hardness, and softness, it can handle a variety of chemical raw materials such as titanium dioxide blocks, plastic particles, resin materials, and rubber products.

Strong durability: Made of high-quality stainless steel and special alloy blades, it has a long service life and is suitable for long-term crushing of chemical raw materials

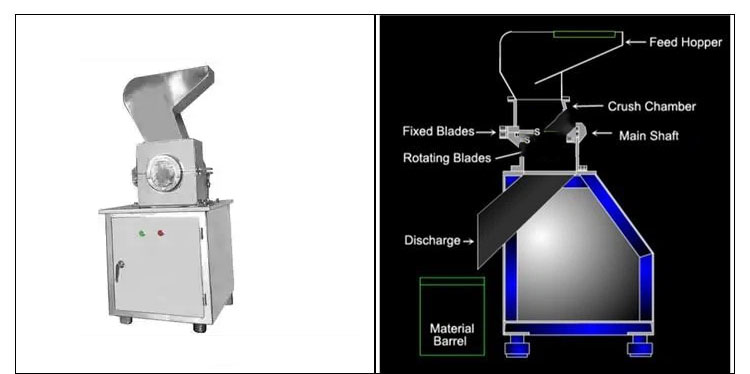

How does the Chemical Materials Coarse Crusher work?

When the Chemical Materials Coarse Crusher is working, the chemical raw materials enter the crushing chamber through the feed hopper. The chemical raw materials are first impacted by the rotating knife and the fixed knife to achieve preliminary crushing. Between the high-speed rotating blade and the fixed knife seat, the chemical raw materials are subjected to strong shear force and are further crushed. The crushed chemical raw materials pass through the screen, and the chemical raw materials that meet the particle size requirements are discharged to the discharge port through the screen hole to complete the entire crushing process

Chemical Materials Coarse Crusher parameters

| Model parameters | CSJ-200 type | CSJ-300 type | CSJ-400 type | CSJ-500 type | CSJ-600 type |

| Production capacity (kg/h) | 50-200 | 150-500 | 300-1000 | 400-1800 | 500-3000 |

| Feed particle size (mm) | ≤50 | ≤100 | ≤120 | ≤180 | ≤200 |

| Grinding fineness (mm) | 0.5-20 (adjustable) | 0.5-20 (adjustable) | 0.5-20 (adjustable) | 0.5-20 (adjustable) | 0.5-20 (adjustable) |

| Spindle speed (r/min) | 800 | 700 | 650 | 600 | 530 |

| Motor power (kW) | 2.2 | 5.5 | 7.5 | 11 | 15-22 |

| Equipment weight (kg) | 250 | 350 | 600 | 800 | 1000 |

| Overall dimensions (mm) | 650×600×1250 | 720×700×1300 | 880×600×1380 | 920×700×1400 | 980×800×1400 |

What are the applications of Chemical Materials Coarse Crusher?

The Chemical Materials Coarse Crusher has a wide range of applications, capable of crushing fibrous, lumpy, fragile, and hard chemical raw materials up to 1500mm in diameter. It can be used to crush resin granules, rubber blocks/waste tire rubber blocks, mineral raw materials, dye/pigment agglomerates, organic intermediates, plastic scraps, and other chemical raw materials. In the plastics industry, it can crush PET bottle flakes and PP/PE films with particle sizes of 2-10mm. In the rubber industry, it can process waste tires and rubber products, with particle sizes adjustable to 3-20mm. It is also suitable for the pre-crushing of various chemical intermediates, providing suitable particle sizes for subsequent reactions. Furthermore, it can be used to recycle and crush medical plastics and rubber stoppers in pharmaceutical excipients, as well as food-grade plastic containers in food packaging.

How to choose a Chemical Materials Coarse Crusher?

When selecting a suitable Chemical Materials Coarse Crusher, it is necessary to consider the properties of the chemical raw materials to be crushed, the required hourly output, the particle size of the crushed material, and whether customization is required.

Material properties (hardness, viscosity, fiber content): Soft plastics (such as PE) can choose standard models, hard plastics (such as PC) need reinforced models; high-viscosity materials require special blade design and greater power; high-fiber materials require special shearing structures

Production requirements: Pilot stage: CSJ-200 model (50-200kg/h); Medium-scale production: CSJ-300/500 model (500-1800kg/h); Large-scale production: CSJ-600 model (3000kg/h)

Particle size requirements: Coarse crushing (10-20mm): standard configuration is sufficient; finer (0.5-5mm): fine screens and high-speed blades are required.

Special requirements: clean requirements (all stainless steel, GMP design), corrosion resistance (special steel versions can be provided for acidic materials), automation (automatic feeding and dust removal systems can be matched)

Chemical Materials Coarse Crusher Customer Case

| Application Scenarios | Feed Particle Size | Finished Product Particle Size | Output | Equipment Model |

| Calcium Carbonate Coarse Crushing | ≤200mm | ≤30mm | 15-20t/h | PC-800×600 |

| Sulfur Block Crushing | 150mm | 20mm | 8-12t/h | PC-600×400 |

| Primary Industrial Salt Crushing | 100mm | 15mm | 10-15t/h | PC-500×350 |

Chemical Materials Coarse Crusher Manufacturer

MACHRISE Chemical Materials Coarse Crusher primarily manufactures the CSJ series of coarse crushers for pulverizing chemical raw materials. These include hammer crushers, claw crushers, and integrated dust-collecting crushers. They can crush various chemical raw materials of different hardnesses, including hard, fibrous, and sticky materials. The entire machine is made of stainless steel, smooth and burr-free, leaving no residue in the crushed material output. The crushing particle size is 0.5-20mm, and the crushing capacity can reach 5000 kg. Factory direct sales are available, with prices starting from as low as $800 USD. Customized products can also be made according to material properties, production requirements, and application scenarios. For example, the feed inlet size can reach 1500×2100mm, and the feeding method can be flanged or enlarged hopper. The discharge port can be located on the side or bottom. The products are ISO and CE certified, ensuring quality, and one-stop service is provided.

Coarse crusher

Coarse crusher Pharmaceutical Materials Coarse Crusher

Pharmaceutical Materials Coarse Crusher

Herbs Coarse Crusher

Herbs Coarse Crusher