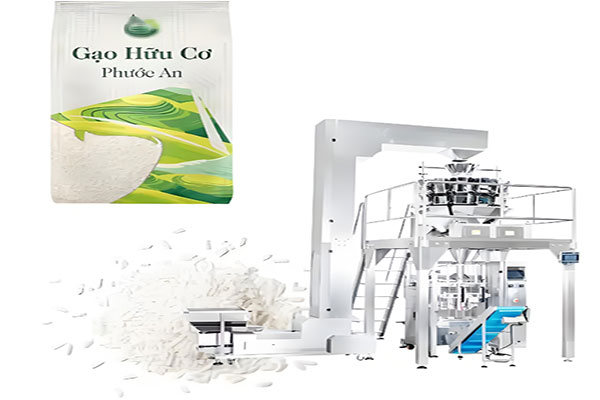

Premade Pouch Rotary Fill And Seal Packing Machine

Premade Pouch Rotary Fill And Seal Packing Machine ,The speed can reach 30-60 bags/minute. Common models are RY-FS30, RY-FS45 and RY-FS60 to meet different production capacity requirements. The price range is from US$18,000 to US$65,000. Applicable bag type: premade flat bag Maximum packaging speed: 30 bags/minute Filling range: 50-1000 grams Sealing method: heat sealing and cold sealing are optional Rotary disk diameter: 800 mm Control system: PLC touch screen operation

What is Premade Pouch Rotary Fill And Seal Packing Machine?

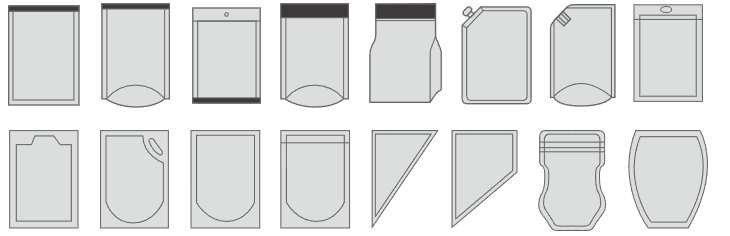

Premade Pouch Rotary Fill And Seal Packing Machine integrates automatic conveying of premade bags, rotary multi-station filling and fast sealing, and is compatible with various bag types such as self-supporting bags, zipper bags, flat bags, etc. The advantages are simple operation, fast bag change, and stable output, which is suitable for filling powder, granules and liquid materials. The speed can reach 30-60 bags/minute. The equipment parameters cover sealing temperature, filling capacity, and number of rotary stations, and support filling of various materials. Common models are RY-FS30, RY-FS45 and RY-FS60 to meet different production capacity requirements. The price range is from $18,000 to $65,000, suitable for production requirements of various sizes.

Types of Premade Pouch Rotary Fill And Seal Packing Machine

Premade Pouch Rotary Fill And Seal Packing Machine is mainly divided into three types: vertical, horizontal, and rotary:

Vertical model: It adopts a vertical working method and occupies a small area, which is suitable for factories with limited space. The machine takes bags from the top, fills, and then seals vertically. It is suitable for materials with good fluidity such as granules and powders, as well as small and medium-sized packaging needs, especially for occasions with high space utilization requirements.

Horizontal model: It adopts a horizontal work process and has a moderate operating height, which is convenient for manual assisted operation and maintenance. This model usually has a large work surface and is suitable for handling larger packaging bags or products of special shapes.

Rotary model: It adopts a turntable design, and the workstations are arranged along the circumference to achieve continuous circulation operation. It is compatible with high-viscosity materials such as liquids and pastes. This model has a high degree of automation and outstanding production efficiency, which is particularly suitable for large-scale continuous production needs.

Three core advantages of Premade Pouch Rotary Fill And Seal Packing Machine

Premade Pouch Rotary Fill And Seal Packing Machine has the advantages of: supporting multiple bag types, compact structure, accurate and fast packaging, etc.:

Advantages of premade bags: supporting multiple premade bag types, strong adaptability; stable shape of premade bags, beautiful packaging; short bag change time, reducing downtime.

Advantages of rotary structure: multi-station design, continuous and fast operation; small footprint, saving production space; coordinated movement, small mechanical wear and long life.

Advantages of filling and sealing: high-precision filling to ensure product consistency; firm sealing, leak-proof and moisture-proof; can adapt to a variety of materials such as powders, particles, and liquids.

Main technical parameters of Premade Pouch Rotary Fill And Seal Packing Machine

The main technical parameters of Premade Pouch Rotary Fill And Seal Packing Machine are as follows:

| MR Series | MR8-200R | MR8-200RW | MR8-300R | MR8-400R |

| Capacity | up to 60bags/min | up to 60bags/min | up to 45bags/min | up to 45bags/min |

| Filling Volume | 5 – 2500g | 5 – 2500g | 10 – 2500g | 10 – 3500g |

| Total Power Consumption | 3.3kw | 3.3kw | 3.3kw | 3.3kw |

| Dimension | 1460 * 2500 * 1400mm | 1710 * 1505 * 1640mm | 2460 * 1830 * 1460mm | 2400 * 1750 * 1600mm |

| Compress Air Requirement (supply by user) | 0.6 – 0.8m³/min | 0.6 – 0.8m³/min | 0.6 – 0.8m³/min | 0.6 – 0.8m³/min |

| Bag Width |

55 – 200mm 2 – 7.9in |

55 – 200mm 2 – 7.9in |

180 – 300mm 7 – 11.8in |

280 – 400mm 11 – 15.7in |

| Bag Length |

≤ 350mm ≤ 13.8in |

≤ 350mm ≤ 13.8in |

≤ 350mm ≤ 13.8in |

≤ 650mm ≤ 25.6in |

Premade Pouch Rotary Fill And Seal Packing Machine price range reference

Depending on the bag specifications and equipment configuration, the price of Premade Pouch Rotary Fill And Seal Packing Machine varies greatly:

Flat bags and simple prefabricated bags: suitable for conventional materials such as granules and powders, with basic configuration and standard output of 30-40 bags/minute, and the equipment price is about $18,000-$25,000.

Stand-up bags or bags with zippers: suitable for complex bag shapes, with strong sealing and display effects, often equipped with intelligent temperature control and precision filling systems, with an output of about 40-50 bags/minute, and a price of $30,000-$45,000.

High-end customized version: supports fast switching of multiple bag types, equipped with multi-head weigher, high-speed rotary station, automatic cleaning, nitrogen flushing and other functions, with a maximum output of more than 60 bags/minute, and the overall price is $55,000-$65,000.

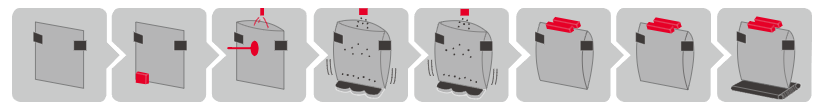

Premade Pouch Rotary Fill And Seal Packing Machine Packaging Process

The workflow of the Premade Pouch Rotary Fill And Seal Packing Machine has been carefully designed, with bag taking, bag opening, filling, sealing, and output, and each link is closely connected:

Automatic bag taking: The manipulator or suction cup device accurately grabs the prefabricated bag from the bag storage area to ensure the accuracy and stability of each bag taking.

Bag opening positioning: The bag opening is opened and fixed to the predetermined position by airflow or mechanical device to prepare for subsequent filling.

Precise filling: According to the preset parameters, the metering device accurately fills the product into the bag. Different materials use special filling systems to ensure filling accuracy.

Venting and sealing: After filling, the necessary venting treatment is carried out, and then the bag opening is sealed by heat sealing or other sealing methods.

Finished product output: The sealed packaging bags are transported to the next process, and the system prepares for the next working cycle.

Premade Pouch Rotary Fill And Seal Packing Machine Packaging Effect

Premade Pouch Rotary Fill And Seal Packing Machine Selection Suggestions

When purchasing Premade Pouch Rotary Fill And Seal Packing Machine, scientific selection should be made based on material type, output, etc.:

Powder materials (such as milk powder, coffee powder, seasoning powder, protein powder)

Recommended configuration: ZX-R8 or ZX-H10 + screw metering system

Features: High-precision servo screw meter is used to effectively prevent dust flying and metering errors, and it is suitable for various bag types such as self-supporting bags and zipper bags. Dust removal hoods and nitrogen filling modules are optional to meet higher requirements for packaging cleanliness and freshness.

Granular materials (such as nuts, candies, tea, pet food, dried fruits)

Recommended configuration: ZX-R8 or ZX-H10 + multi-head combination weigher

Features: Multi-head weigher achieves high-speed and high-precision weighing, suitable for irregular or large granular materials. The packaging process is stable and fast, and can be equipped with metal detection, weight re-inspection, and rejection devices to ensure product quality and food safety.

Liquid materials (such as soy sauce, beverages, detergents, and cosmetic concentrates)

Recommended configuration: ZX-R6 or ZX-R8 + liquid pump system

Features: Equipped with optional liquid dosing devices such as gear pumps/plunger pumps/diaphragm pumps, precise quantity control, and anti-drip design to ensure clean and tidy sealing. Suitable for ordinary flat bags and self-supporting bags with nozzles, with strong adaptability.

Paste materials (such as ketchup, peanut butter, jam, skin cream)

Recommended configuration: ZX-R8 or ZX-H10 + piston pump filling system

Features: Suitable for high viscosity and high flow resistance materials, high filling accuracy and smooth discharge. Optional heating and heat preservation device and anti-drip system.

Premade Pouch Rotary Fill And Seal Packing Machine Solution

Premade Pouch Rotary Fill And Seal Packing Machine has strong versatility and flexibility, and can adapt to a variety of bag types (such as self-supporting bags, zipper bags, four-side sealing bags, etc.) and materials of different forms:

Block material packaging: Suitable for packaging regular or irregular block products such as nuts, candies, chocolates, biscuits, and medicines. The machine can be equipped with a vibration leveling device to ensure that the product is evenly distributed in the bag. For fragile products, buffer filling technology can be used to reduce damage.

Liquid packaging solutions: Covering beverages, condiments, daily chemical liquids and other products. The equipment is equipped with a drip-proof filling system to avoid contamination; for liquids that are prone to foaming, a defoaming device can be integrated. The viscosity adaptability is wide, and it can handle liquids from water to oil.

Paste material packaging: suitable for viscous materials such as cosmetics, ointments, and food sauces. The equipment is equipped with a filling pump with a special structure to ensure smooth delivery of the paste; for pastes of different viscosities, the filling parameters can be adjusted to achieve the best effect.

Powder material packaging: For powder products such as milk powder, coffee powder, and additives, the packaging adopts a dust-proof design to effectively reduce dust pollution. At the same time, an anti-static device is configured to avoid powder adsorption affecting the metering accuracy. A vibration compaction device can also be selected according to demand to increase the packaging density.

Premade Pouch Rotary Fill And Seal Packing Machine Manufacturer Selection

Premade Pouch Rotary Fill And Seal Packing Machine manufacturers are mainly concentrated in Zhejiang, Jiangsu, Guangdong, and Henan in China. As a manufacturer in Henan, our factory has advantages in this field with rich industry experience and technology. The models produced by our factory include DH-RF300, DH-RF500 and DH-RF800, which are suitable for different production capacities and material requirements, with stable equipment and compact structure. Our factory provides a variety of models, pays attention to full-process services, ensures stable operation of equipment, and wins the trust of customers.