Plastic Bottle Belt Conveyor

The price of Plastic Bottle Belt Conveyor varies depending on its type, conveying capacity, material and degree of customization, usually ranging from US$200 to US$6,000.

Power: 2.2 kW

Size: Customized

Width or diameter: Customized

Voltage: 110v/220v/240v

Speed: Adjustable, 5 m/min, 20 m/min

Capacity: 80 t/h

What is Plastic Bottle Belt Conveyor?

Plastic Bottle Belt Conveyor is a key equipment to realize continuous material transfer. It mainly drives the continuous belt to run through the driving device, thereby carrying and moving plastic bottles. According to different conveying requirements, this type of conveyor presents a variety of structural forms. For example, the flat belt conveyor is suitable for horizontal or small-angle inclined linear conveying; the sidewall belt conveyor is equipped with sidewalls on both sides of the conveyor belt, which is particularly suitable for the regularization and constraint of material flow; and the climbing belt conveyor uses the inclined conveyor belt to achieve the height lifting or lowering of plastic bottles to meet the height connection requirements between different production equipment. These types of belt conveyors together constitute an important part of the plastic bottle material handling system.

What are the types of Plastic Bottle Belt Conveyor?

Plastic Bottle Belt Conveyor is crucial in packaging and production lines, and flat belt conveyors, skirt baffle belt conveyors, and climbing/downhill belt conveyors are three commonly used types. They each have unique design and application advantages to adapt to different conveying needs, whether it is horizontal straight conveying, large angle inclination or vertical lifting.

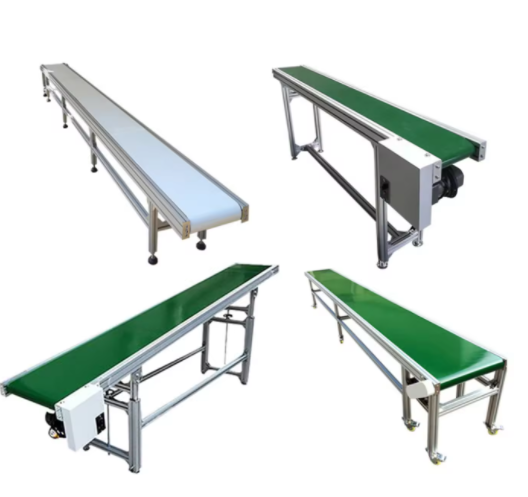

The flat belt conveyor uses a continuous, flat conveyor belt made of rubber, PVC, PU or other synthetic materials, with a flat belt body and moderate friction. This conveyor is widely used for linear horizontal conveying of plastic bottles, and can also be used for small-angle inclined conveying, especially for plastic bottles with a stable bottom that are not easy to roll or tip over. Its main advantages are simple structure, smooth operation, low noise and easy maintenance.

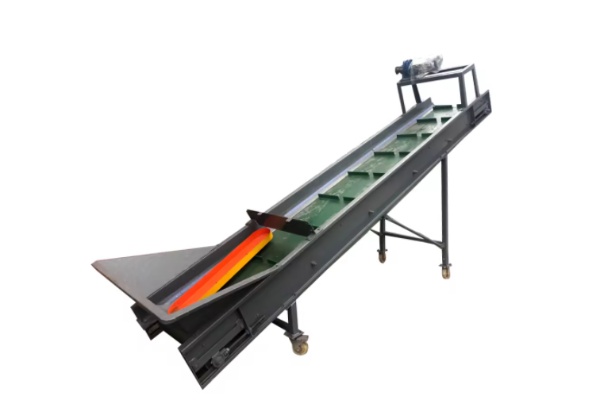

Unlike flat belt conveyors, skirt baffle belt conveyors have lateral baffles (cleats) and sidewalls on the conveyor belt surface. The baffles are designed to increase the driving force on the material and prevent it from sliding down when tilted; while the skirts can effectively prevent the material from falling off the edge. This design makes it mainly used for large-angle tilting conveying or vertical lifting of plastic bottles, especially in scenarios where space is limited and the material height needs to be quickly raised. The shape and height of the baffles will be customized according to the size and tilt angle of the bottle. Its main advantage is that it can achieve large-angle conveying, thereby effectively saving space.

The characteristic of climbing/downhill belt conveyors is that the conveyor belt is tilted at a certain angle to achieve the height of the material. Depending on the size of the tilt angle, this conveyor may need to be equipped with skirt baffles to ensure stable material transportation. It is mainly used for conveying plastic bottles between equipment at different heights.

Basic parameters of Plastic Bottle Belt Conveyor

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

What are the advantages of Plastic Bottle Belt Conveyor?

The advantages of Plastic Bottle Belt Conveyor are closely integrated with the characteristics of plastic bottles, which are mainly reflected in the following aspects:

Smooth transportation and reduced bottle damage: Plastic bottles, especially empty bottles or lightweight bottles, are often light, easy to fall over and easy to wear. The belt conveyor provides a continuous, flat and moderately frictional conveying surface to ensure that plastic bottles can be conveyed in a stable posture. This greatly reduces the risk of falling, scratching, deformation and even breakage caused by bumps, collisions or sudden stops and starts during transportation. This smooth transportation is particularly important for products with high appearance requirements, such as transparent bottles or printed bottles.

Strong adaptability and flexible layout: The layout of plastic bottle production lines is often complex and changeable, and needs to cope with space restrictions, height changes and direction turns. Belt conveyors can achieve horizontal, inclined, and even curved conveying through turning mechanisms to meet the changing process and site restrictions of production lines.

Low noise operation: Plastic bottles may generate noise when they contact and rub with other components during transportation. Compared with chain conveyors, belt conveyors are usually quieter and have a relatively low friction coefficient, which can effectively reduce the noise level in the production workshop.

What are the applications of Plastic Bottle Belt Conveyor?

As a general material conveying equipment, Plastic Bottle Belt Conveyor has a wide range of application scenarios, not limited to specific industries or fields, and mainly covers the following aspects:

Smooth and continuous material transportation: In scenarios where plastic bottles need to be transported from one location to another, belt conveyors provide a smooth and continuous solution. Whether it is empty or filled bottles, it can ensure that the material remains stable during the transportation process, effectively reducing the damage that may be caused by the bottle tipping, collision or mutual friction. For example, material turnover between different equipment on the production line, or batch transfer in the storage area.

Change in material height or position: Belt conveyors can play a role when the vertical height or horizontal position of plastic bottles needs to be changed. By adjusting the inclination angle of the conveyor, plastic bottles can be transported uphill or downhill, lifted from a lower station to a higher platform, or transported from a high place to a lower receiving point. At the same time, through the turning belt conveyor, the direction of material travel can be changed without interrupting the conveying flow, adapting to the complexity of the site layout.

Plastic Bottle Belt Conveyor Cases

Plastic Bottle Belt Conveyor is widely used in the packaging, beverage, food and plastic recycling industries. Its diverse design can handle different forms of plastic materials, from lightweight empty plastic bottles to irregular plastic granules. In beverage and food production lines, flat belt conveyors are a common plastic bottle conveying solution. They are mainly responsible for the linear horizontal conveying of plastic bottles, such as conveying empty bottles from the blow molding machine to the filling line, or conveying the filled finished bottles to the labeling machine and packaging area. In addition to plastic bottles, belt conveyors are also widely used for the conveying of plastic granules. In the plastic recycling and regeneration industry, a large amount of waste plastics are crushed and cleaned to form irregular plastic granules. These granules need to be conveyed from the cleaning tank to the dryer, and then from the dryer to the extruder or packaging area. In short, the Plastic Bottle Belt Conveyor has become an indispensable conveying equipment in the field of plastic product production, packaging and recycling with its versatility, adaptability and efficiency.

Manufacturers of Plastic Bottle Belt Conveyor

Plastic Bottle Belt Conveyor manufacturers provide customers with a variety of conveying solutions to meet the complex needs of plastic bottles and related plastic materials in the production, packaging and recycling processes. Manufacturers are able to provide highly customized conveyor designs based on customers' specific production line layouts, material characteristics and site restrictions. This means that not only can the length, width and height of the conveyor be adjusted, but also unique baffles, sides and guides can be designed for specific bottle types to ensure that the bottles are stable and do not fall during transportation. In terms of conveying output, by selecting the appropriate belt width, speed and drive system, the conveyor can handle small-scale production from thousands of bottles per hour to large-scale automated production lines with tens of thousands of bottles per hour. The width of the belt conveyor can be flexibly adjusted according to the size of the bottle and the number of rows to be conveyed, from a narrow belt for a single row of bottles to a wide belt for parallel conveying of multiple rows of bottles. The conveying distance can be extended from a short-distance connection section of several meters to a long-distance conveying system of tens of meters across a workshop or floor, which requires manufacturers to accurately calculate and optimize the belt tension, support structure and drive power. Overall, Plastic Bottle Belt Conveyor manufacturers are committed to providing reliable conveying solutions that meet customer-specific needs through customization capabilities.

Plastic Bottle Belt ConveyorIn practical applications, its stability and adaptability are important aspects to consider. The normal operation of the equipment depends on the tension of the conveyor belt, the reliability of the drive system, and the stability of the supporting structure. For plastic bottles of different shapes, sizes and weights, it is necessary to select a belt of appropriate width and a corresponding conveying speed to ensure smooth movement of materials and avoid accumulation or jamming. At the same time, daily cleaning and maintenance, such as regular inspection of conveyor belt wear, cleaning of residual materials, and lubrication of transmission components, are important links to ensure long-term continuous operation of the equipment. This type of conveyor provides a specific material handling method for the transfer of plastic bottles in various production environments.