Helix conveyor

The price of Helix conveyor ranges from US$200 to US$9,000 due to its different materials, sizes, types, drive systems and additional functions.

Load capacity: 500 kg

Power: 3-30kw

Size: Customizable

Material: Carbon steel/stainless steel

Voltage: 220/380V

Rotation speed: 45-70 R/Min

What is Helix conveyor?

The basic function of a Helix conveyor is to transport bulk materials, such as powder, granular, and small block materials, from one location to another. According to the structural form, helix conveyors are mainly divided into shafted and shaftless types. The shafted helix conveyor conveys materials by rotating spiral blades welded or connected to the central shaft; the shaftless helix conveyor has no central shaft and relies on the spiral blades to slide in the trough for transportation, which is more suitable for conveying viscous or winding materials. According to the conveying direction and inclination, common types include horizontal, vertical, and inclined. The conveying capacity of a helix conveyor is affected by parameters such as spiral diameter, pitch, and speed. The conveying distance depends on the overall length of the equipment, and longer conveyors may require intermediate supports.

What are the types of helix conveyors?

Helix conveyors can be divided into many types according to their structure, conveying direction, whether there is a central axis, and special uses to adapt to different material characteristics and working conditions. According to the conveying direction and installation form, they can be divided into horizontal Helix conveyors and inclined Helix conveyors. According to the spiral blade structure, they can be divided into shafted Helix conveyors and shaftless Helix conveyors. The following is a detailed introduction to its main types:

The characteristic of a shafted helix conveyor is that the spiral blades are wound around a solid or hollow shaft, and the materials are pushed by the rotation of the shaft. The advantages of this type of conveyor are simple structure and stable conveying capacity. Their common forms are U-shaped trough type (open type) and cylindrical type (closed type).

The shaftless Helix conveyor has no central axis, only the spiral blades rotate directly in the U-shaped trough or tube. This design makes it have strong anti-winding ability, especially suitable for conveying materials that are easy to wind, easy to clog, sticky or have high moisture content.

The characteristic of the horizontal Helix conveyor is that the spiral body is arranged horizontally, which is mainly used for horizontal transportation of materials. It is the most common form of Helix conveyor and is suitable for horizontal transmission needs of various bulk materials.

The spiral body of the inclined Helix conveyor is arranged obliquely to achieve inclined lifting or conveying of materials.

The spiral body of the vertical Helix conveyor is arranged vertically and is specially used for vertical lifting of materials. This type is particularly suitable for situations where the site is limited or the material needs to be lifted directly from the bottom to the top.

Basic parameters of Helix conveyor

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

What are the advantages of Helix conveyor?

As a common material conveying equipment, Helix conveyor has many advantages. First of all, it has a simple and compact structure, exquisite design and small footprint. It can effectively utilize space whether in narrow spaces or in situations where vertical or inclined conveying is required. Secondly, Helix conveyor has sealing properties, which can effectively prevent dust spillage and material contamination. In terms of conveying direction, Helix conveyor is flexible. In addition, Helix conveyor has a variety of material handling functions. While conveying materials, it can also achieve stirring and mixing to allow the materials to fully blend; through built-in coolants or heating agents, the materials can be cooled, heated or insulated, and even preliminarily dried. Helix conveyor also has strong adaptability and can convey a variety of bulk materials such as powder, granular, small blocks, and even some sticky or easily entangled materials (such as through shaftless Helix conveyor). In terms of operation, Helix conveyor drives the spiral shaft to rotate through the motor-driven reducer, ensuring smooth and reliable operation and relatively low noise, thereby ensuring continuous and stable transportation of materials.

What are the applications of Helix conveyor?

Helix conveyor is often used for the transportation of bulk materials. It can move various powdery, granular and small block materials in horizontal, inclined and even vertical directions. This includes dry, fluid powders and small granular materials such as flour, starch, cement, coal powder, etc., as well as the use of shaftless Helix conveyor to handle sludge, wet garbage, wet slag and other materials that are sticky or easy to entangle. For materials with strong abrasiveness, Helix conveyor made of wear-resistant materials can be used. In addition, Helix conveyor is also commonly used in the storage and discharging of materials. It can stably take out materials from the bottom of the silo, hopper or storage tank and convey them to the next link. With the stirring effect of the spiral blade, it also has the function of mixing and stirring materials, and can evenly mix a variety of bulk materials.

Helix conveyor is particularly suitable for material transportation in special environments. For example, its closed design (such as tube type) can effectively prevent the leakage of dusty, toxic, corrosive or volatile materials. In short, Helix conveyor plays an important role in the transportation, storage, mixing, metering and other links of bulk materials with its wide range of material conveying, compact structure, excellent sealing and flexible operation.

What are the structures of Helix conveyor?

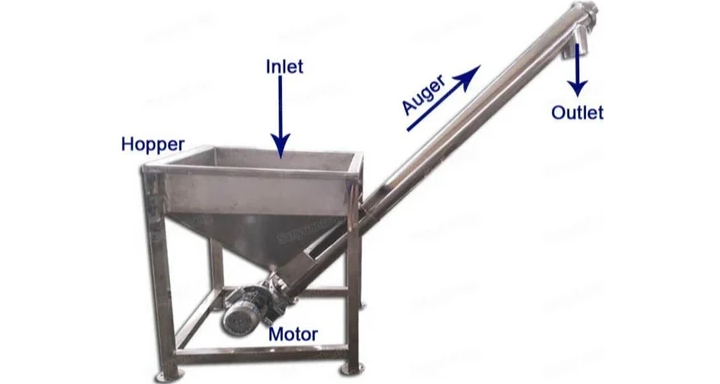

Helix conveyor is a conveying device that uses rotating spiral blades to push materials along a U-shaped groove or a closed tubular shell. Its structure is relatively simple, but the components work together to achieve continuous material transportation. Helix conveyor is mainly composed of the following core components:

Conveyor body

Spiral blades: usually made of steel plates, forming a continuous spiral surface around the central axis. When the spiral shaft rotates, the blades push the material along the axial direction. There are various types of blades, including solid spirals, belt spirals, and paddle spirals.

U-shaped groove or round tube shell: This is the fixed part where the spiral blades are located, used to hold and restrain materials.

Cover: If it is a U-shaped groove type, it is usually equipped with a cover to prevent material spillage or dust pollution.

Drive device

Motor: Provides power, usually a three-phase AC motor.

Reducer: Used to reduce the speed of the motor and increase the torque to meet the working requirements of the Helix conveyor.

Coupling: Connect the motor, reducer and spiral shaft to transmit power.

Base: supports the drive unit and fixes it to the ground or bracket.

Feed port and discharge port

Feed port: the entrance of the material into the conveyor, usually designed as a funnel or square to facilitate the smooth entry of the material.

Discharge port: the outlet of the material leaving the conveyor, which can be designed at the end or multiple discharge ports can be set in the middle to meet different process requirements.

Helix conveyor manufacturers

As a common material conveying equipment, Helix conveyor has many manufacturers, and each manufacturer has differences in product type coverage and customization capabilities. These manufacturers usually provide a variety of standard models of Helix conveyors to meet the basic market needs for different materials, conveying volumes and working conditions. At the same time, many manufacturers also have strong customized design and manufacturing capabilities for specific application scenarios. In terms of product types, Helix conveyor manufacturers can provide equipment based on different spiral blade structures, such as shafted Helix conveyors and shaftless Helix conveyors. In terms of shell form, U-shaped trough type and round tube type are standard configurations, which are suitable for open conveying and closed, dust-proof and pollution-proof conveying environments respectively. In addition, manufacturers will also provide horizontal, inclined and even vertical Helix conveyors according to the conveying direction to meet the diverse needs from short-distance translation to high-level lifting. Manufacturers also produce Helix conveyors with special purposes, such as cooling/heating types with jackets, stirring types with mixing functions, and spiral feeders for precise feeding. Helix conveyor manufacturers have customization capabilities and can carry out non-standard designs based on detailed parameters provided by customers, including the physical and chemical properties of materials (such as particle size, density, abrasiveness, viscosity, temperature, corrosiveness), conveying capacity, conveying distance, inlet and outlet locations, installation space restrictions, and special explosion-proof, wear-resistant, and corrosion-resistant requirements.

How much does a Helix conveyor cost?

The price of a Helix conveyor varies depending on many factors, so it is difficult to give a uniform figure, but it usually ranges from $200 to $9,000. The key factors that affect its cost include material, specification, structure type, drive system, and additional features and configurations. Material selection is the primary determinant of price. Ordinary carbon steel has the lowest cost and is suitable for general non-corrosive materials; while stainless steel (such as 304 or 316L) is significantly more expensive than carbon steel. If conveying abrasive or high-temperature materials, more expensive special alloy steel or wear-resistant materials may be required. Specifications directly affect the cost, including spiral diameter, conveying length, conveying capacity, and installation form (horizontal, inclined or vertical). Generally speaking, the larger the diameter, the longer the length, the larger the conveying capacity, and the higher the design and manufacturing requirements of vertical conveyors, the higher the price. The structure type is also an important consideration. The shafted Helix conveyor is a standard configuration with a relatively low cost; while the shaftless Helix conveyor can effectively handle sticky or easily entangled materials due to its unique center shaft-free design, but the manufacturing cost is usually higher. In terms of shell form, the closed round tube type usually has higher sealing and strength requirements than the open U-shaped groove type, and the price may be slightly higher. The configuration of the drive system, such as the size of the motor power, the brand and type of the reducer, will also significantly affect the total price.

Helix conveyor moves bulk materials in the trough through a rotating spiral structure. Different types of Helix conveyors can be selected according to different conveying needs and material characteristics. The shaft type is suitable for conveying materials with good fluidity, while the shaftless type is more suitable for handling sticky or winding materials. In current industrial production, Helix conveyor is used in the handling and conveying of various materials, such as powder, granules or waste. Choosing a suitable Helix conveyor requires considering practical factors such as the nature of the material, the required conveying volume and the conveying distance.