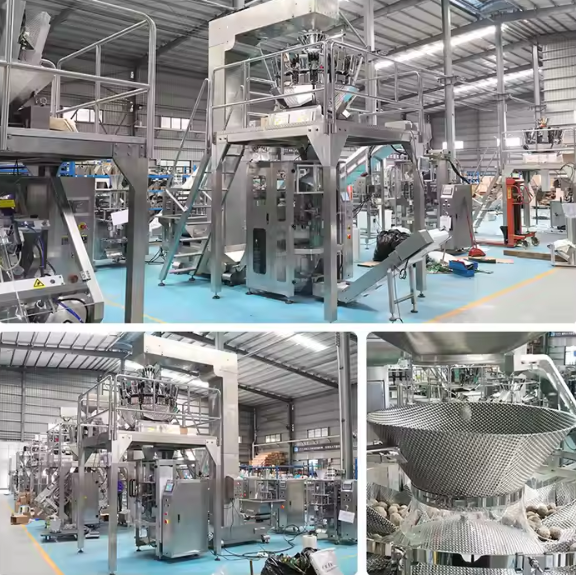

Multihead Packaging Machine Manufacturer

Wednesday November-26 2025 11:38:15

Multihead Packaging Machine produces products with 10, 14, or 16 weighing heads for precise weighing and rapid packaging of granules, powders, liquids, and small blocks of material. Typical production speeds for multihead packaging machines range from 40 to 200 bags per minute, depending on the number and configuration of the weighing heads. The machines manufactured by this multihead packaging machine manufacturer are equipped with PLCs and color touchscreens, making parameter setting, recipe storage, and operation monitoring very easy, ensuring stable operation and accurate weighing for each machine.

Multihead Packaging Machine Manufacturer Pricing Features

Multihead Packaging Machines are competitively priced, offered in materials such as carbon steel and stainless steel. Generally, a full stainless steel body is more expensive than a machine made of ordinary stainless steel or powder-coated carbon steel.

Semi-automatic multihead packaging machines typically have 2-4 heads and require manual assistance for bag loading or bagging. They are suitable for small to medium-sized production lines. Packaging speeds are 20-50 packs/minute, and prices range from $7,000 to $15,000.

Standard fully automatic multihead packaging machines automate the entire process from bag making, metering, filling to sealing. They are configured with 6-10 heads, with packaging speeds of 40-100 packs/minute, and prices range from $15,000 to $30,000.

High-performance multi-head packaging machines utilize a higher number of heads and a more advanced control system, suitable for large-scale manufacturing enterprises and high-speed production needs. They can be configured with 12-18 heads, achieving packaging speeds of 80-200+ packs/minute, and are priced between $30,000 and $50,000.

Customized multi-head packaging machines offer tailored solutions for special products such as large-volume, viscous liquids, products with accessories, or special materials such as aluminum foil and composite films. Pricing depends on the specific customization plan.

Multihead Packaging Machine Dimensions

Due to varying production space requirements, manufacturers customize multihead packaging machines in different specifications. The length of the packaging bags ranges from 80mm to 320mm, and the width from 50mm to 200mm. The machine dimensions vary depending on the number of heads. A 10-11 head machine is approximately L 1600–1730 × W 1070–1200 × H 1110–1540 mm. A 14-16 head machine is approximately L 1700–1860 × W 1100–1500 × H 1110–1540 mm. A 20 head machine is approximately L 1665–1900 × W 1450–1665 × H 1450–1990 mm; some machines including elevators, filling or bag feeding mechanisms can reach heights exceeding 2,000 mm. For customized sizes, provide the manufacturer with specific materials, target bag dimensions, expected production capacity, and workshop space constraints so that a suitable machine size can be recommended or customized.

Multihead Packaging Machine Case Study

A food company producing potato chips, shrimp crackers, roasted nuts, biscuits, and other food products had multiple semi-automatic packaging production lines. These lines required a large amount of manual labor for bagging, sealing, and sorting. Furthermore, frequent changes in packaging film and equipment adjustments were necessary for different specifications and product categories, resulting in excessively long changeover times. After introducing an 8-head fully automatic multihead combination weighing packaging machine, the packaging speed stabilized at 95 bags/minute, an improvement of over 150% compared to the old equipment. The defective product rate dropped from 3% to below 0.3%. The rapid changeover capability enabled the company to flexibly handle urgent and small-batch orders.

There are many multi-head packaging machine manufacturers on the market, such as Machrise, Waylog Automation Solutions, and Koyka Electronics Private Limited. As a professional multi-head packaging machine manufacturer, our machines can be shipped to various countries and regions. We can produce 8-head, 10-head, or advanced 14-head food multi-head weighing and packaging machines according to your needs, and provide samples for you to try out to verify the equipment's operational stability and accuracy. We can also provide customized solutions for special materials (such as powders and liquids), such as anti-stick hoppers and negative pressure dust collection devices. From design and production to after-sales service, we always put our customers first, providing customized services to meet the packaging needs of different industries and materials.