Grain Coarse Crusher

A machine that relies on mechanical force to crush various grain raw materials into coarse particles that meet the requirements, preparing for subsequent secondary processing or fine crushing. It is often used for the initial crushing of grains. The material is available in carbon steel, 304 stainless steel or 316L stainless steel. The crushing fineness can be adjusted according to demand. Its price is between $600-$8500

Output: 100-2000kg/h

Coarse grinding (20-60 mesh): suitable for feed processing, brewing raw materials, etc.

Medium grinding (60-120 mesh): suitable for ordinary flour and food raw material processing

Fine grinding (120-300 mesh): used for high-end food and health care raw materials

Ultrafine grinding (300 mesh and above): used for high-end food additives and pharmaceutical excipients

What is Grain Coarse Crusher?

Grain Coarse Crusher is a coarse crusher used for primary grain processing. It crushes whole grains into coarse particles that meet the requirements, but not fine powder, through mechanical forces such as extrusion and impact, in preparation for subsequent animal feed processing, food brewing or further crushing of coarse materials. It can crush different types of grain raw materials such as wheat, corn, rice, soybeans, sorghum, oats, etc. to different finenesses such as 20-300 mesh, with an hourly crushing capacity of 100 kg to 5 tons, meeting the crushing needs from laboratory to industrial production. It is commonly used in grain processing, feed production, food processing and other industries, but cannot be used for crushing high-moisture or sticky grains, which are prone to clogging the machine or shortening the machine's service life.

Compared with traditional manual grinding, Grain Coarse Crusher is made of stainless steel, which is not easy to rust and easy to clean, can prevent cross-contamination of grains, and complies with GMP and HACCP food hygiene standards. It has two crushing devices: wear-resistant alloy blades or hammers to meet the crushing needs of grains of different hardness.

What types of Grain Coarse Crusher are there?

Grain Coarse Crusher options vary depending on the hardness and size of the grain being crushed, as well as the fineness of the grain being crushed. These include hammer-type, toothed disc-type, and turbine-type, with output sizes ranging from 20-80 mesh, 80-120 mesh, and 120-300 mesh.

Hammer Grain Coarse Crusher: Utilizes high-speed rotating hammers to impact and crush grains, delivering a high crushing force of 500-2000 kg/h. The output particle size ranges from 20-80 mesh, making it suitable for crushing medium-hard grains such as corn, wheat, sorghum, and beans.

Geared Disc Grain Coarse Crusher: Utilizes sprocket engagement to crush grains, delivering a uniform particle size between 80-120 mesh and a gentle crushing process. It is suitable for crushing brittle or fragile grains such as rice, oats, and buckwheat, with a crushing capacity of 800-3000 kg/h.

Turbine Grain Coarse Crusher: Utilizes high-speed turbine-generated airflow and shear force to crush grains, achieving fine crushing and high efficiency. It is commonly used for grains requiring fine or coarse crushing, such as millet, quinoa, and barley, with a particle size range of 120-300 mesh.

What are the advantages of Grain Coarse Crusher?

All food-contact parts of the Grain Coarse Crusher are made of 304 stainless steel, which is clean and hygienic and meets food hygiene standards. Compared with manual crushing, it can improve grain processing efficiency, with an output of 500-5000kg/h, an efficiency increase of more than 70%. The crushing mesh size is adjustable from 20-300 mesh, and the discharge mesh size of the crushed grain can be adjusted by adjusting the screen or rotation speed to meet the production needs of different processing industries. Its crushed particles are highly uniform (deviation ≤5%), which can reduce material waste in subsequent processing and ensure the stability of finished product quality. It also supports customization of product parameters such as product size, material, screen aperture, etc. to adapt to the crushing needs of grains of different hardness.

How does Grain Coarse Crusher work?

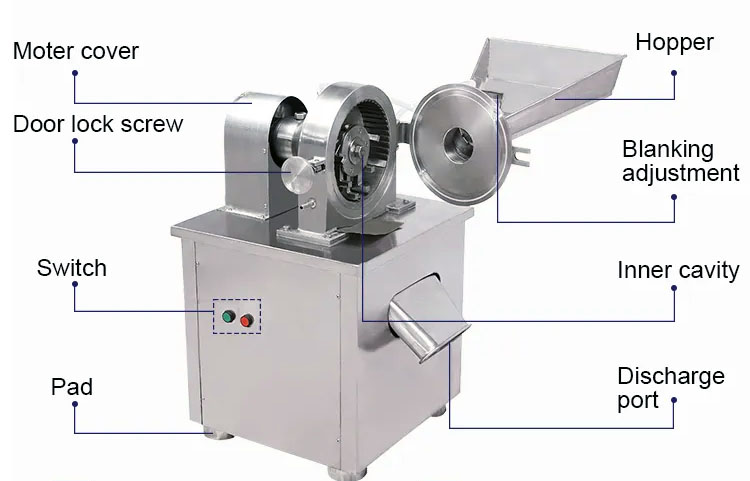

When the Grain Coarse Crusher is working, grain is evenly fed into the crushing chamber from the feed port. The hammer/toothed disc rotates at high speed, performing a series of operations such as impact and shearing on the grain particles. The crushed grains are filtered through the screen, and the grain powder that meets the fineness is discharged from the discharge port, while the grain that does not meet the fineness is intercepted in the crushing chamber and continues to be crushed.

Grain Coarse Crusher Parameters

| Model | Grinding fineness | Output (kg/h) | Power (kW) | Applicable grain type |

| WF-20 | 20-80 mesh | 500-1000 | 4-7.5 | Corn, wheat |

| WF-40 | 80-120 mesh | 300-800 | 5.5-18.5 | Rice, beans |

| WF-60 | 120-200 mesh | 100-300 | 7.5-37 | Ultrafine rice flour, seasoning powder |

What are the applications of Grain Coarse Crusher?

Grain Coarse Crusher can be used in grain processing, feed processing, food manufacturing and industrial brewing industries to crush different types of grains as pretreatment for subsequent processes. It can crush wheat, corn, rice, soybeans, mung beans, red beans, potatoes, sweet potatoes, buckwheat, quinoa, oats, corn, soybean meal, barley, highland barley and other grains of different hardness. It can also be used to crush grains with a moisture content of 10%-20%, such as fermented soybeans.

How to choose a Grain Coarse Crusher?

When choosing a Grain Coarse Crusher, you need to consider the hardness, fineness and yield of the grains. For medium-hard grains such as corn and wheat, use a hammer type; for fragile grains such as rice, oats, and buckwheat, use a toothed disc type; for fine and coarse crushing of small-grain grains such as millet, quinoa, and barley, choose a turbine type; the fineness range is adjustable from 20 to 300 mesh, and you can choose according to your needs. For yield, a mobile type can be selected for small-scale crushing <500kg/h, and an industrial type coarse crusher can be selected for large-scale crushing needs.

Grain Coarse Crusher Manufacturer

MACHRISE Grain Coarse Crusher manufacturers manufacture equipment made of polished 304 or 316L stainless steel, ensuring cleanliness and ease of cleaning. They offer a comprehensive range of models, including hammer, gear, and turbine models to suit different grain hardnesses. Customized models can be tailored to grain properties and crushing requirements (such as refrigeration, vacuum, and dust removal), or equipped with accessories. These models include explosion-proof, air-cooled, mobile, and dust-removal devices, meeting diverse crushing needs.

Grain Coarse Crusher FAQs

How much does a Grain Coarse Crusher cost?

The price of a Grain Coarse Crusher ranges from $600 to $8,500, depending on the model, output, and features. Small home or laboratory-grade units, such as the LY-15 (80-100 kg/h), typically cost $600 to $1,500. Medium-sized commercial units (such as the LY-35 widened model with a 500-800 kg/h output) cost approximately $1,200 to $5,500. Large industrial-grade units use more materials and higher-powered drive units, and are therefore more expensive, costing approximately $3,000 to $8,500+.

Can a Grain Coarse Crusher crush hulled grains or high-fiber grains?

Most grain coarse crushers can crush hulled grains or high-fiber grains. However, when crushing hulled grains, the feed rate should be reduced and the screen gap should be adjusted to 5-10mm to avoid clogging. When crushing high-fiber grains such as straw and vines, they need to be pre-processed with a hay chopper or manually before being crushed by a hammer mill. For some hard materials such as coffee beans and nuts, a claw crusher can be selected because it can withstand greater impact force.

Chinese Herb Grinder Machine

Chinese Herb Grinder Machine Seeds Coarse Crusher

Seeds Coarse Crusher