Plastic Coarse Crusher

It is used in plastic recycling production lines to crush large or irregularly shaped waste plastics into smaller plastic flakes or granules for easy recycling. Its price ranges from $1,000 to $10,700.

Processing capacity: 50 - 1500KG/H

Feed size: 300 - 1000mm

Discharge particle size: 0.5 - 20mm

Motor power: 3.5 - 150 kW

Roller speed: 120 - 520rpm

What is Plastic Coarse Crusher?

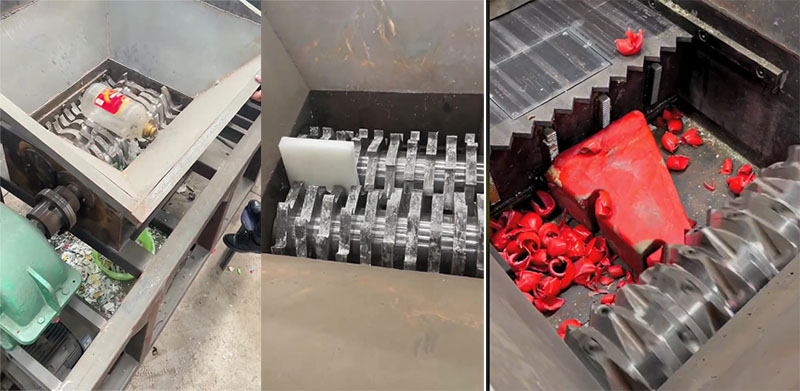

Plastic Coarse Crusher is a machine used to crush large, irregular plastic raw materials or waste into desired sizes before plastic recycling and processing. It mainly uses motor-driven blades to cut and tear plastic to reduce its volume. It can crush the material into flakes or granules of 0.5-20mm, providing uniform material for subsequent grinding or granulation processes. Depending on the model of the machine, the crushing capacity ranges from 50 kg to 1500 kg per hour.

The plastic coarse crusher can crush various types of plastics, including injection molding waste, plastic pipes, films, and packaging materials. However, the appropriate crushing blades must be selected based on the type of plastic. For example, crushing hard plastics like PP and ABS requires a high-torque, high-strength disc crusher; while for soft plastics like PE film, an anti-tangling toothed roller crusher is needed; and for mixed plastic materials containing metallic foreign objects, a machine with a magnetic separation mechanism is required.

What types of Plastic Coarse Crusher are there?

There are three main types of plastic coarse crushers: hammer crushers, shear crushers, and dual-shaft crushers. They differ in their crushing principles, feed size, output, and the types of plastics they can crush.

Hammer crusher plastic coarse crusher: It achieves crushing by striking plastic with rotating hammers. It has a high crushing ratio and uniform output particle size, but high-speed operation generates heat, so the melting point of the plastic must be considered. It can crush plastics within 200-1000mm in diameter, with a processing capacity of 400-1500 kg/h. It can be used to crush medium-hardness plastics such as PVC pipes, PP injection molded parts, and PE films.

Shear crusher plastic coarse crusher: It crushes plastic through the mutual shearing between blades, which are detachable and replaceable. It can crush hard or soft plastics, such as plastic bottles, plastic shells, injection molding regrind, and plastic woven bags. It can also be used for crushing corrosive engineering plastics containing glass fiber. The feed size should not exceed 800mm, and the hourly processing capacity can reach 1000 kg.

Dual-shaft Plastic Coarse Crusher: This type of crusher uses two counter-rotating blade shafts to squeeze and shear plastic. The blade spacing can be adjusted according to requirements, making it suitable for crushing plastics of different hardness. It is commonly used for crushing bundles of film or large plastic parts. The feed opening size can reach 2800mm, and the hourly processing capacity is 1500-4000kg/h. It is commonly used for crushing large plastic products such as plastic buckets and car bumpers.

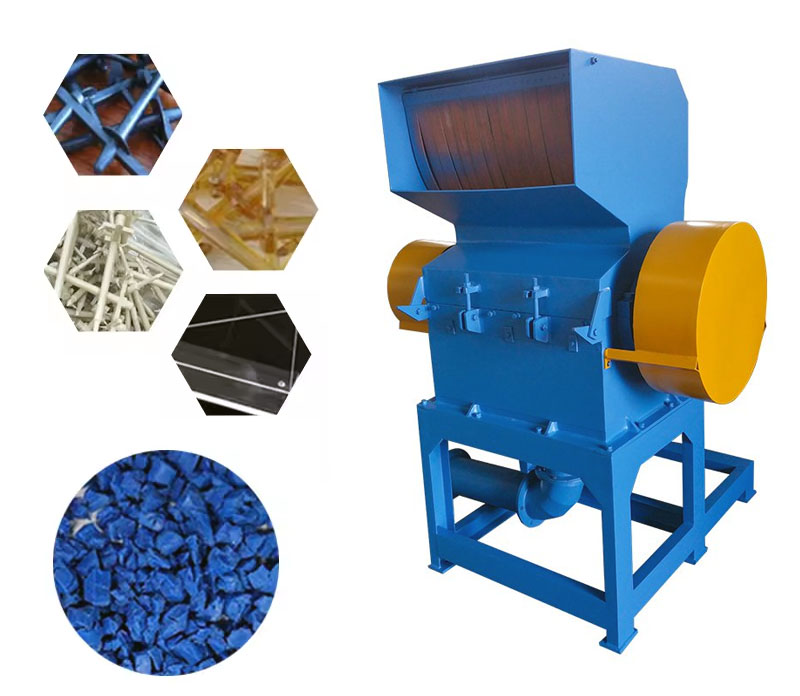

What are the advantages of Plastic Coarse Crusher?

The Plastic Coarse Crusher's body and blades are made of alloy steel/high-chromium steel, a material that can withstand the impact of trace impurities in plastics. The blades are also highly resilient and not easily broken. The output particle size is 0.5-20mm, and the output size can be controlled by changing the screen. The plastic particles are uniform and suitable for crushing various forms of plastic raw materials such as hard plastics, soft plastics, films, and fibers. It has a large crushing capacity of up to 4000 kg, making it suitable for everything from household use to large-scale plastic recycling and processing in factories. In addition, it supports customized blade structure, screen size, and other parameters. For some parts that generate heat during crushing, a water cooling system can be added to reduce overheating losses.

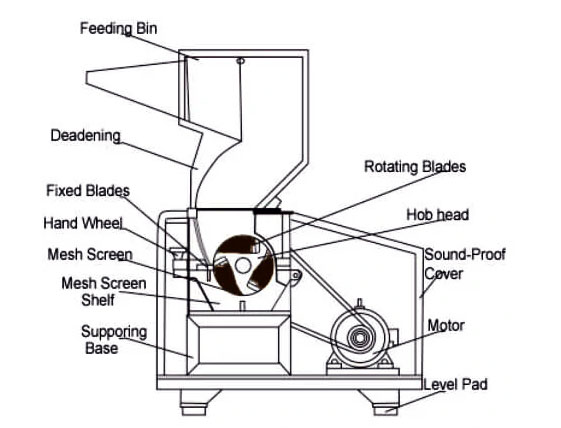

How does the Plastic Coarse Crusher work?

When the Plastic Coarse Crusher is working, plastic waste enters the crushing chamber through the feeding port, and the shear force formed by the high-speed rotating moving knife and the fixed knife crushes the plastic. The crushed plastic particles pass through the screen, and those that meet the size enter the collection system, while the oversized particles continue to be crushed.

Plastic Coarse Crusher Parameters

| Model | PS-180 | PS-230 | PS-300 | PS-400 | PS-500 | PS-600 | PS-800 | PS-1000 | PS-1200 |

| Power | 2.2kW | 4kW | 5.5kW | 7.5kW | 11kW | 15kW | 22kW | 37kW | 45kW |

| Capacity (kg/h) | 100-150 | 150-200 | 200-300 | 400-600 | 500-700 | 600-800 | 700-900 | 800-1,000 | 800-1,200 |

| Rotating blades | 9 | 6 | 9 | 12 | 15 | 18 | 24 | 30 | 36 |

| Fixed blades | 2 | 2 | 2 | 2 | 2 | 4 | 4 | 4 | 4 |

| Screen mesh size | 8mm | 8mm | 10mm | 10mm | 10mm | 12mm | 12mm | 12mm | 12mm |

| Weight (kg) | 240 | 340 | 480 | 660 | 900 | 1,400 | 1,950 | 2,500 | 3,000 |

| Feed port size (mm) | 180*136 | 230*170 | 300*210 | 400*240 | 500*300 | 600*310 | 800*400 | 1,000*400 | 1,200*500 |

| Dimensions (mm) | 730*440*900 | 1,000*700*1,050 | 1,100*800*1,200 | 1,300*900*1,400 | 1,450*1,050*1,500 | 1,500*1,250*1,720 | 2,000*1,400*2,100 | 2,000*1,600*2,100 | 2,300*2,100*2,800 |

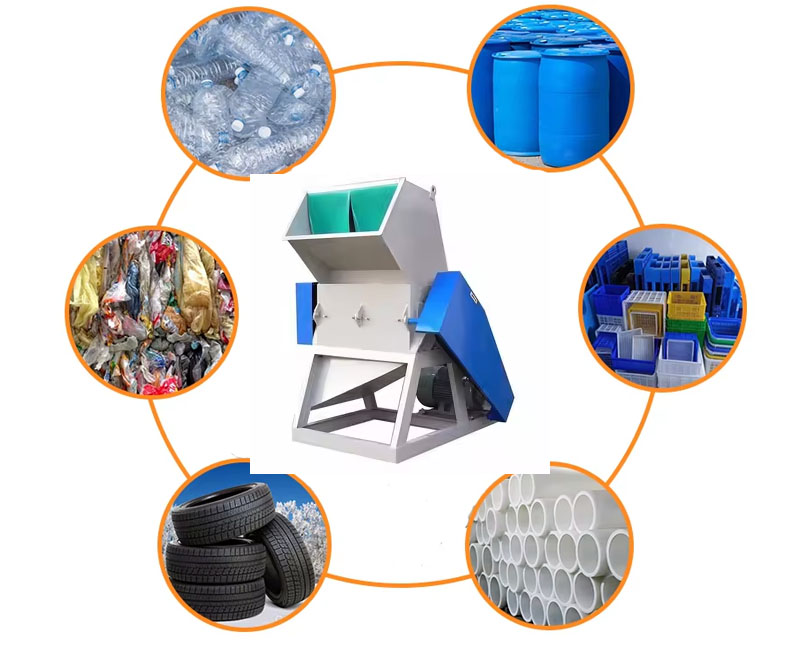

What are the applications of Plastic Coarse Crusher?

Plastic Coarse Crusher can be used for crushing and recycling plastic products in the plastic processing process. It can handle scraps from plastic product manufacturing and crush plastic waste in solid waste disposal. Crusherable plastic products include PE plastic film, shopping bags, plastic bottles, PP plastic boxes, turnover boxes, bottle caps, PVC plastic pipes, profiles, toys, PS foam boxes, fast food boxes, ABS plastic appliance shells, automotive plastic parts and plastic pipes, PET bottle sheets, HDPE milk bottles, PP woven bags, etc. It can also process plastic sheets, plastic filaments, waste plastic parts and other plastic products in different forms.

How to Choose Blades for a Plastic Coarse Crusher?

The choice of blades varies depending on the properties of the plastic products being crushed, such as hardness, shape, sealing, flexibility, impurity content, and flowability. For hard and brittle plastics like PVC, PA, and ABS, high-hardness materials like SKD11 and Cr12MoV blades are preferred. These blades undergo quenching treatment to improve wear resistance and prevent chipping. For high-toughness plastics like PE, PP, and TPE, sharp and tough toothed or spiral blades, such as 9CrSi and W6Mo5Cr4V2, are needed. These blades prevent material entanglement and tearing through hooking and shearing. For thicker block plastics like plastic buckets and sheets, wider blades (≥50mm width) and thicker blades (≥15mm thickness) are recommended for strong impact resistance. When processing plastics containing impurities such as metal inserts and fiberglass reinforcement, high-chromium alloy blades with passivated edges are recommended to reduce wear and damage from impurities.

Plastic Coarse Crusher Customer Case

| Customer Types and Application Scenarios | Crushed Material | Feed Size | Discharge Size | Crushing Capacity (per Hour) |

| A large-scale waste plastic recycling plant in Germany, used for the pre-treatment of centralized urban waste plastics, providing uniform material for subsequent granulation processes. | Mixed waste plastics including PE plastic buckets, PP sheets, PET beverage bottles, and ABS electrical appliance casings, containing small amounts of impurities. | ≤500mm×500mm | 20-50mm | 800-1200kg |

| A US-based automotive parts injection molding plant uses a system to immediately recycle scraps and defective products generated during production, achieving material recycling. | PP injection molding scraps, defective ABS dashboard panels, and defective PC automotive light housings. | ≤200mm×200mm | 10-30mm | 200-300kg |

| An Indian agricultural cooperative recycles waste plastic film and irrigation pipes used in agricultural production to reduce environmental pollution. | PE greenhouse film, PVC irrigation pipes, PP seedling trays, and used pesticide bottles. | ≤300mm×300mm | 15-40mm | 300-400kg |

| A food packaging printing factory in China uses substandard plastic packaging film and recycled waste turnover boxes to reduce solid waste in the factory area. | PET food packaging film, PP turnover boxes, HDPE bottle cap material | ≤400mm×400mm | 12-35mm | 500-700kg |

Plastic Coarse Crusher Manufacturer

MACHRISE Plastic Coarse Crusher manufactures a range of products for plastic crushing, including hammer crushers, shear crushers, twin-shaft shredders, and jaw crushers. Depending on the type of plastic being crushed, selectable blades include claw blades, shovels, and sheet blades. Custom blade sizes and thicknesses are also available upon request. Furthermore, integrated crushing and dust collection systems and cooling systems can be added to meet specific crushing needs.

Hammer mill

Hammer mill Rubber Coarse Crusher

Rubber Coarse Crusher Cyclone pulse vacuum crusher

Cyclone pulse vacuum crusher Grain Coarse Crusher

Grain Coarse Crusher