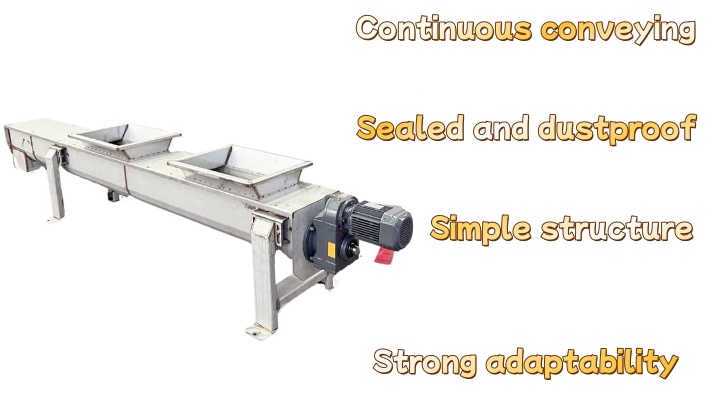

Industrial Screw Conveyor

The price of Industrial Screw Conveyor varies greatly due to its model, material, conveying capacity, motor power, degree of automation. The price ranges from US$300 to US$6,000.

Voltage: 220V, 380V

Power: 1kW, 2KW, 3KW, 5KW

Productivity: 500L/hour

Size: 1500mm L * 200mmW/customized

Rotation speed: 45-70 R/Min

Material: Stainless steel/Carbon steel

What is Industrial Screw Conveyor?

Industrial Screw Conveyor can be mainly divided into four categories according to its installation angle and structural characteristics: horizontal, inclined, vertical and shaftless. Each type provides solutions for specific conveying scenarios and material characteristics. Whether it is necessary to handle a large amount of powdered materials, medium-flow granular materials, or to lift materials to a certain height, screw conveyors can provide corresponding support. Its conveying capacity ranges from several tons to hundreds of tons per hour, and the conveying distance of a single machine is usually within tens of meters, providing flexible material transfer capabilities for production lines of different sizes.

What are the types of Industrial Screw Conveyor?

Industrial Screw Conveyor is a material conveying equipment widely used in various industries. It mainly pushes the material forward along the trough body through rotating spiral blades. According to its different installation angles and structural characteristics, it can be divided into four categories: horizontal, inclined, vertical and shaftless. The following will introduce these four types in detail from the aspects of conveying capacity, conveying distance and structural characteristics.

Horizontal Screw Conveyor

Conveying capacity: The conveying capacity has a wide range and can be adjusted according to the screw diameter and speed. It is usually suitable for medium to large conveying capacity requirements.

Conveying distance: The conveying distance is relatively short, generally within tens of meters. If long-distance conveying is required, multiple units are usually required in series.

Structural features: Horizontal installation, the spiral shaft is placed horizontally in a U-shaped or O-shaped trough. The structure is simple and easy to manufacture, install and maintain. Good sealing can achieve fully enclosed conveying, reducing dust pollution and material loss. Suitable for conveying a variety of loose materials such as powder, granules, and small blocks.

Inclined screw conveyor

Conveying capacity: The conveying capacity is lower than that of the horizontal screw conveyor, because the inclination angle will increase the internal friction of the material and affect the conveying efficiency. The larger the inclination angle, the smaller the conveying capacity.

Conveying distance: The conveying distance is usually also short, similar to the horizontal conveyor.

Structural features: The spiral shaft is placed at a certain angle, usually between 0° and 45°. Compared with the horizontal conveyor, it occupies a smaller area at the same height, which is suitable for places with limited space. It has both conveying and lifting functions, and can transport materials from low to high.

Vertical Screw Conveyor

Conveying capacity: The conveying capacity of vertical screw conveyor is relatively small, and it is mainly used to lift materials. Its conveying capacity is greatly affected by the screw speed and material characteristics.

Conveying distance: The conveying distance is the vertical height, which is usually used to lift materials to a higher height.

Structural features: The screw shaft is placed vertically, and the material is lifted under the centrifugal force of the high-speed rotating spiral blades. It occupies a smaller area than all types of screw conveyors, saving space. It can achieve a larger lifting height, which is suitable for high-position unloading or feeding to high-altitude equipment. It is usually suitable for conveying powdery and small granular materials with good fluidity, non-abrasive or weakly abrasive.

What are the advantages of Industrial Screw Conveyor?

The reason why Industrial Screw Conveyor is widely used in various industries is that it has many significant advantages. These advantages make it an ideal choice for conveying bulk materials such as powders, granules, and small blocks.

Simple structure and easy installation and maintenance: The screw conveyor is relatively simple in design and consists of spiral blades, troughs, drive devices and support components. This simple structure makes the equipment very convenient to manufacture, install and maintain daily. When parts need to be replaced or troubleshooting is required, the operation is also relatively easy, which reduces downtime and maintenance costs.

Good sealing: The screw conveyor can usually achieve fully enclosed transportation. This means that the material will not be exposed to the external environment during the conveying process, effectively reducing dust flying and material leakage. This is especially important for conveying toxic, harmful, flammable, explosive or moisture-sensitive materials.

Flexible conveying direction, multi-point feeding and discharging: The screw conveyor can not only achieve horizontal conveying, but also inclined and vertical conveying, and can easily achieve multi-point feeding and multi-point unloading. This flexibility enables it to adapt to different production process layouts and material flow requirements, such as taking materials from multiple silos or distributing materials to multiple processing points.

Small footprint and high space utilization: Especially in vertical conveying applications, the screw conveyor occupies a small area and can save valuable industrial space to the greatest extent.

Stable conveying and controllable conveying volume: The screw conveyor continuously pushes the material through the rotation of the spiral blade, making the material conveying process smooth and continuous. At the same time, by adjusting the speed of the screw, the material conveying volume can be easily controlled to meet the requirements of different production processes for feed speed and achieve precise quantitative conveying.

Parameters of Industrial Screw Conveyor

| Model |

Diameter (mm) |

Pitch (mm) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

Rotating speed (r/min) |

Capacity (m³/h) |

|

| Small | 100 | 100 | 100 | 140 | 2.2 | 112 | 1.7 | 90 | 1.4 | 71 | 1.1 |

| 125 | 125 | 125 | 125 | 3.8 | 100 | 3 | 80 | 2.4 | 63 | 1.9 | |

| 160 | 160 | 160 | 112 | 7.1 | 90 | 5.7 | 71 | 4.5 | 56 | 3.6 | |

| 200 | 200 | 200 | 100 | 12.4 | 80 | 9.9 | 63 | 7.8 | 50 | 6.2 | |

| Small | 250 | 250 | 250 | 90 | 21.8 | 71 | 17.2 | 56 | 13.6 | 45 | 10.9 |

| 315 | 315 | 315 | 80 | 38.8 | 63 | 30.5 | 50 | 24.2 | 40 | 13.4 | |

| 400 | 400 | 355 | 71 | 62.5 | 56 | 49.3 | 45 | 38.6 | 36 | 31.7 | |

| Large | 500 | 500 | 400 | 63 | 97.7 | 50 | 77.6 | 40 | 62 | 32 | 49.6 |

| 630 | 630 | 450 | 50 | 138.5 | 40 | 110.8 | 32 | 88.6 | 25 | 69.3 | |

| 800 | 800 | 500 | 40 | 198.5 | 32 | 158.8 | 25 | 124.1 | 20 | 99.3 | |

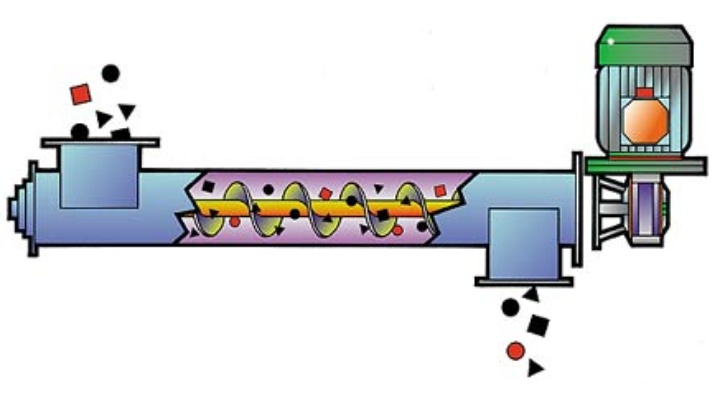

How does an industrial screw conveyor work?

The operating principle of an industrial screw conveyor is based on the interaction between the spiral rotation and the weight of the material. Its core component is a rotating shaft with spiral blades, typically enclosed in a U-shaped or cylindrical housing. When a motor drives a reducer, rotating the screw shaft, the material enters the housing through the feed port. Due to the thrust of the spiral blades on the material, the material's own weight, and the friction between the material and the housing walls, the material does not rotate with the screw. Instead, the material is continuously conveyed forward along the space between the spiral blades and the housing walls, driven by the axial thrust generated by the rotating spiral blades. The operating principle of a screw conveyor can be compared to the movement of a screw being screwed into wood. As the screw rotates, it uses the thrust of the threads to propel itself axially. Similarly, the spiral blades of a screw conveyor act like continuously rotating threads, "twisting" the material from one end to the other. During the conveying process, materials tend to move forward under the action of the screw, but some will lag behind due to gravity and friction. This relative motion together constitutes the continuous conveying process. The conveyor's inclination angle significantly affects its operating principle. During horizontal conveying, materials are primarily subjected to axial thrust, resulting in high conveying efficiency. However, as the inclination angle increases, the material's gravity creates a downward sliding force, which partially offsets the screw's thrust, resulting in a decrease in conveying capacity. To overcome this effect, it is often necessary to increase the screw speed or adjust the pitch to ensure stable material lifting. Screw conveyors, with their simple structure, stable operation, and easy sealing, are widely used for short-distance conveying of various powdered, granular, and bulk materials, such as cement, grain, mineral powder, and chemical raw materials.

What are the applications of Industrial Screw Conveyor?

Due to its unique advantages, Industrial Screw Conveyor is widely used in various scenarios where bulk materials need to be handled. Whether it is powder, granular or small block materials, as long as they are loose, non-adhesive or can handle adhesive materials through specific designs, screw conveyors can effectively convey and transfer. This includes but is not limited to conveying raw materials from silos to production lines, and smoothly feeding stored materials such as grains, mineral powder, cement, plastic granules, etc. to the next process. Material transfer between different processes, in the production process, semi-finished products or waste materials are transported from one equipment to another to achieve automated continuous production. Collection and transportation of finished products or waste materials, collecting qualified products or waste slag, dust, etc. generated in the production process, and transporting them to the packaging area, storage area or waste treatment area. In addition, screw conveyors can not only convey horizontally, but also lift and distribute materials according to demand. When the production line needs to lift materials from a lower position to a higher position (for example, to feed materials into a high mixer, reactor or storage tank), inclined and vertical screw conveyors can complete the task and effectively utilize space. Screw conveyors can be designed to receive materials at multiple points or accurately distribute materials to different outlets, thereby achieving material mixing, diversion or quantitative supply. This is very useful in scenarios where multiple raw materials need to be mixed or a single raw material needs to be distributed to multiple production lines. Some variants of screw conveyors, especially shaftless screw conveyors, enable them to handle materials that are difficult for ordinary conveyors to handle, such as sticky or easily entangled materials, high temperature or corrosive materials, toxic, harmful or volatile materials, etc. In some cases, screw conveyors are not just simple conveying tools, but also have some auxiliary functions, such as mixing or stirring, cooling or heating, etc. In short, the Industrial Screw Conveyor is a versatile and adaptable material handling equipment, and its application range covers almost all industrial production processes that require bulk material conveying, lifting, distribution or special handling.

Industrial Screw Conveyor Case Studies

Industrial screw conveyors, with their simple structure, excellent sealing, and easy maintenance, play an important role in material conveying across multiple industries. They are primarily used to convey various bulk materials, including powdered, granular, and bulk materials. In the agricultural sector, screw conveyors are widely used to transport grain, feed, fertilizer, and seeds. For example, in grain silos, they transfer grain from one storage bin to another or load it onto transport vehicles. In food processing plants, screw conveyors are commonly used to transport raw materials such as flour, sugar, starch, and spices. They can also be used to handle by-products such as pomace and meat scraps. Their airtight structure effectively prevents contamination during transportation. The chemical industry handles a variety of powdered and granular raw materials, such as plastic pellets, carbon powder, fertilizer, and additives. Screw conveyors, with their excellent sealing properties, effectively prevent material leakage and are particularly suitable for handling toxic or corrosive materials. In the construction materials industry, screw conveyors are key equipment for transporting materials such as cement, lime powder, coal powder, and sand and gravel, and are commonly used in concrete mixing plants and cement plants. The mining and metallurgical industries often handle highly abrasive and high-density materials such as ore, coal, and coke. Screw conveyors operate reliably in these environments, transporting materials from equipment such as crushers and grinders to the next process. Its durable design and customizable materials make it adaptable to harsh working conditions. Overall, the Industrial Screw Conveyor is an indispensable material handling equipment in industrial production lines due to its strong adaptability and customizability, which can be adjusted to the specific needs of different industries.

Industrial Screw Conveyor Manufacturers

The selection of Industrial Screw Conveyor requires in-depth consideration of several key factors. The first is the material properties, including its viscosity, abrasiveness, particle size, water content, temperature, and whether it is corrosive or flammable. For example, conveying abrasive materials requires the selection of more wear-resistant spiral blade materials; conveying sticky materials may require a shaftless screw conveyor to avoid blockage. The second is the conveying parameters, including the required conveying volume (tons or cubic meters per hour), conveying distance, lifting height, and the installation angle of the conveyor (horizontal, inclined or vertical). Different conveying requirements will directly determine the core parameters such as screw diameter, speed, motor power, and drive mode. In addition, the working environment is also a factor that cannot be ignored, such as whether there is dust, moisture, high temperature or low temperature, which will affect the selection of equipment materials and the requirements for sealing level. Manufacturers can carry out professional engineering design based on the detailed material data, process flow charts and site conditions provided by customers, optimize the screw diameter, pitch, blade form, and even tailor-make special structures such as multi-point inlet and outlet, mixing and stirring functions, cooling or heating jackets, etc. In addition, the customization capability is also reflected in the diversity of material selection, such as corrosion-resistant alloy steel for corrosive materials, special heat-resistant steel for high-temperature environments, and food-grade stainless steel. Manufacturers have deep technical accumulation and flexible production capacity, and can cope with various complex and unique conveying needs, ensuring the matching of equipment and production lines, thereby improving efficiency and reducing operating risks.

Industrial Screw Conveyor has become an indispensable material handling tool in industrial production due to its intuitive working principle and diverse structural forms. By selecting the appropriate screw diameter, pitch and speed, and considering the actual characteristics of the material, this type of equipment can stably complete the conveying tasks from dust to small pieces of material. Whether it is necessary to transfer materials from one container to another or to achieve continuous material supply in the production process, screw conveyors can provide reliable support. Its structural characteristics allow it to be arranged in different spatial layouts, including narrow areas or areas that require vertical lifting. In practical applications, the reasonable selection of equipment type, material and drive mode is the key to ensure a smooth material conveying process.