Paint Powder Vacuum Loading Machine

Paint Powder Vacuum Loading Machine uses negative pressure airflow generated by a vacuum pump to automatically convey powder, granular, and flake materials through a closed pipeline.

Power: 1.5-5.5 kW (customizable)

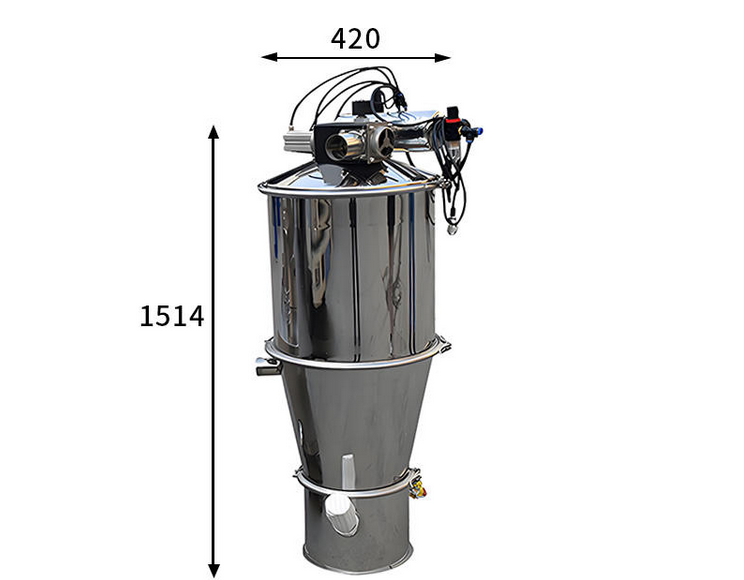

Dimensions (L*W*H): Depends on the specific model

Material: 304/316 stainless steel

Voltage:220V/380V/415V or customizable upon request

Customization: Acceptable

Type: Pneumatic/Electric/Continuous

Applicable Materials: Titanium dioxide, calcium carbonate, talc, barium sulfate, carbon black, iron oxide pigments, resins, solvents, and liquids

What is a Paint Powder Vacuum Loading Machine?

Paint Powder Vacuum Loading Machine automatically transfers various paint raw materials from storage containers to process stages such as reactors, dispersers, or packaging lines, eliminating manual handling. It features sealed conveying, zero dust leakage, and strong adaptability. It meets specialized operating requirements such as explosion-proof and corrosion-resistant, and can be customized to achieve high-precision metering, online cleaning, and seamless integration with automated production lines. It is a key piece of equipment for improving the safety, efficiency, and environmental friendliness of paint production.

Paint Powder Vacuum Loading Machines are available in two materials.

Paint Powder Vacuum Loading Machines The machine is constructed of either 304 or 316 stainless steel, each offering advantages in corrosion resistance, hygiene standards, service life, and cost-effectiveness. 304 stainless steel is suitable for general coatings and the food and pharmaceutical industries, while 316 stainless steel is more suitable for highly corrosive coatings and the chemical industry.

304 stainless steel: Offers excellent corrosion resistance, resisting corrosion from common coating materials like titanium dioxide and kaolin, but exhibits slightly weaker performance in highly corrosive environments, such as those containing chlorides. Its smooth, easy-to-clean surface meets food and pharmaceutical hygiene standards, effectively reducing material adhesion and cross-contamination.

316 stainless steel: Based on 304 stainless steel, it incorporates molybdenum for even greater resistance to chloride corrosion. It offers enhanced resistance to coating materials containing organic solvents or highly corrosive ingredients. It also meets food and pharmaceutical hygiene standards, and its superior corrosion resistance makes it particularly suitable for the production of coatings requiring high sanitation requirements.

What are the advantages of a paint powder vacuum loading machine?

Paint Powder Vacuum Loading Machine With its explosion-proof design and stainless steel construction, the machine offers significant advantages in paint production, particularly in terms of safety, durability, and hygiene.

Explosion-proof Structure: Utilizing three layers of protection: explosion-proof panels, flame-retardant panels, and anti-static film. The explosion-proof panels are made of ultra-high molecular weight polyethylene fiber, offering strong impact resistance and effectively blocking explosion shock waves.

Inert Gas Protection: When conveying organic solvent-based paints, the system can be inflated with inert gases such as nitrogen to maintain a low-oxygen environment, preventing the formation of explosive mixtures and ultimately eliminating combustion conditions.

Corrosion Resistance: Material contact parts are constructed of 304 or 316L stainless steel, offering excellent acid, alkali, and solvent resistance. This allows for long-term, stable conveyance of various paint raw materials and prevents material contamination caused by equipment corrosion.

Easy Cleaning and Maintenance: The quick-release design allows for quick disassembly and cleaning of components such as filters and piping. Compatible with CIP and SIP procedures, it meets the strict cleanliness requirements of the paint industry.

Improved Production Safety: The explosion-proof design reduces the risk of dust explosions to negligible levels, protecting operators and minimizing losses to the company.

Paint Powder Vacuum Loading Machine Workflow

From raw material storage to precise conveying, the Paint Powder Vacuum Loading Machine enables one-touch operation, ensuring enclosed and dust-free operation! Its explosion-proof design and intelligent control easily adapt to various paint production scenarios.

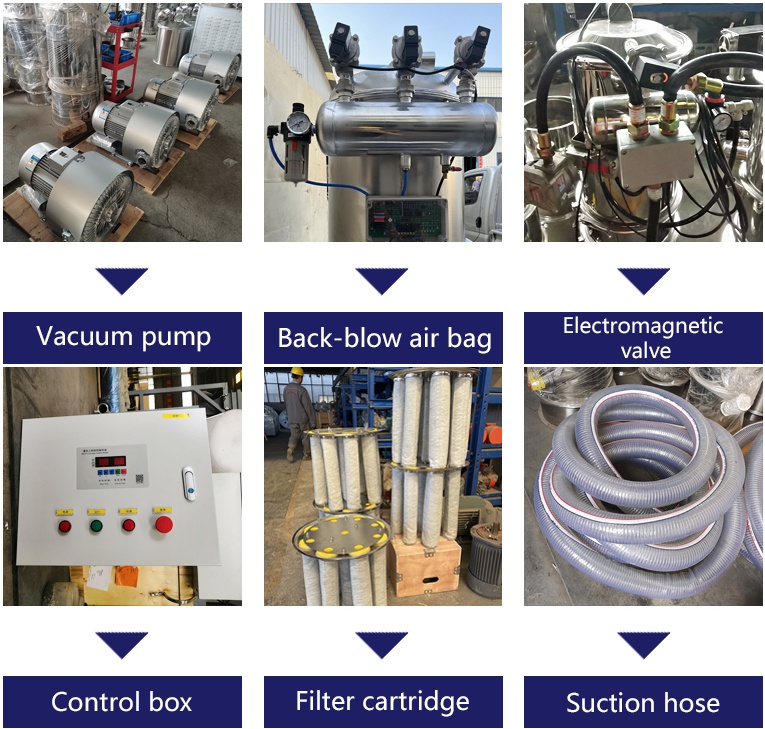

Feeding Phase: The vacuum pump activates, creating negative pressure in the silo, and material is drawn into the silo through the suction tube.

Separation Phase: The mixed airflow enters the silo, where the material settles due to gravity, while air is removed through the top filter.

Discharge Phase: When the material in the silo reaches the set volume, the vacuum pump stops, the bottom discharge valve opens, and the material is discharged by gravity.

Backflush Cleaning Phase: After discharge, compressed air automatically backflushes the filter to prevent clogging and prepare for the next intake.

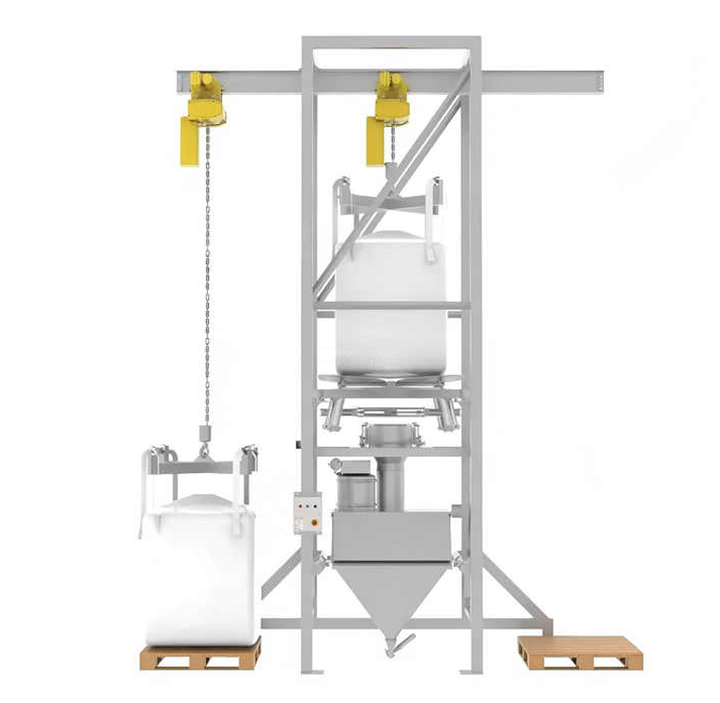

Paint Powder Vacuum Loading Machine Structure

The Paint Powder Vacuum Loading Machine is designed around "enclosed negative pressure conveying." The core functions consist of four modules: the power system, the conveying system, the separation system, and the control and auxiliary systems. Each structure is customized to the characteristics of the paint raw materials.

Vacuum generator: The mainstream uses an oil-free screw vacuum pump or a compressed air vacuum generator. The oil-free design prevents oil contamination of the paint raw materials and meets the conveying needs of various materials such as titanium dioxide and resin.

Explosion-proof motor: For hazardous environments with solvent evaporation and dust, the power system is equipped with an explosion-proof motor. The housing features a flameproof structure to prevent internal sparks from contacting flammable and explosive gases, ensuring safe operation of the equipment.

Suction assembly: Includes the suction nozzle and suction pipe. The suction nozzle is customized according to the raw material form. When conveying powders, a "Venturi-type suction nozzle" is used to optimize airflow distribution and prevent powder agglomeration. When conveying mixed "powder + liquid" raw materials, a "Venturi-type suction nozzle" is used. The "dual-channel suction nozzle" uses a primary channel to suck powder and a secondary channel to suck liquid, achieving preliminary premixing.

Conveying pipes: The pipe diameter is selected based on the conveying volume and material characteristics. Large-diameter pipes are used for powder conveying to reduce the risk of blockage. When conveying viscous resins, a pipe heating device can be installed to reduce resin viscosity and ensure smooth conveying.

Paint Powder Vacuum Loading Machine Technical Parameters

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

What coating materials are suitable for the Paint Powder Vacuum Loading Machine?

With its corrosion-resistant, anti-adhesion, and airtight moisture-proof design, the Paint Powder Vacuum Loading Machine is suitable for various raw materials in paint production, including powders, liquids, and pastes. It covers the material conveying needs of mainstream coatings, including solvent-based, water-based, and powder-based coatings.

Powder coatings: Can handle inorganic pigments / Fillers and organic powder additives. Inorganic additives include titanium dioxide, calcium carbonate, talc, barium sulfate, carbon black, and iron oxide pigments. The equipment utilizes mirror-polished piping and pulse-cleaning filters to reduce adhesion and cross-contamination. Adjustable airflow speeds and anti-bridging hoppers prevent clogging and ensure uniform conveying.

Liquid/viscous coatings: For resins, solvents, and liquid additives, the equipment features corrosion-resistant materials and temperature-controlled design. Resins such as acrylic, epoxy, polyurethane, and alkyd resins are constructed with 316L stainless steel or PTFE to prevent adhesion and corrosion, allowing for precise dosing and mixing of paints.

Mixed-form coatings: Suitable for premixing "powder + liquid," eliminating subsequent mixing steps. Examples include premixing "titanium dioxide + deionized water" in water-based coatings and "carbon black + xylene" in solvent-based coatings.

Specialty coating raw materials: Customized equipment is available for high-specification coating raw materials. Powder coating raw materials such as epoxy resin powder and polyester powder, as well as upgraded PTFE... High-efficiency filter elements with membranes prevent leaks; anti-corrosion/high-temperature resistant paint raw materials such as glass flakes and ceramic powders.

What are the requirements for paint conveying with a paint powder vacuum loading machine?

A vacuum loading machine must meet multiple requirements for paint conveying: it must be compatible with the paint material's characteristics, utilize corrosion-resistant materials, address fluidity issues, and implement explosion-proof and static control measures. Conveying parameters must match production capacity, distance, height, and speed to ensure continuous and stable conveying. Hygiene and safety must comply with relevant standards, utilize easy-to-clean materials, achieve sealed conveying to prevent leaks, and be equipped with safety devices. Environmental adaptability must include the ability to handle varying temperatures and humidity levels. Enhanced sealing, dust-proofing, and purification measures must ensure stable operation in dusty or corrosive environments, effectively completing paint conveying tasks.

Paint Powder Vacuum Loading Machine Customization Case Studies

As a source manufacturer, we have extensive production experience and numerous customer cases. We tailor our solutions to our customers' production sites and provide them with appropriate, safe, and high-speed loading equipment that seamlessly integrates with their production lines.

Automotive coating production line:Requires conveying high-gloss coating raw materials containing organic solvents, requiring a conveying accuracy of ±0.5% and seamless integration with the DCS system. The customized solution utilizes 316L stainless steel explosion-proof construction and a nitrogen inertization system to eliminate explosion risks. High-precision weighing modules and dynamic compensation algorithms are integrated to ensure real-time calibration of conveying volume.

Food contact coating plant:Requires conveying FDA-compliant titanium dioxide and polyethylene wax microparticles. Equipment materials must be FDA-certified to prevent cross-contamination and support CIP/SIP cleaning and sterilization. The customized solution utilizes 316L electropolished stainless steel and features a removable PTFE sintered membrane filter element. A quick-release design with no dead angles and clamp-type sealing piping reduces cleaning time.

Chemical coating storage center:Requires conveying 25kg bags of pigment powder to a 15-meter-high reactor at a single transfer rate of 2 tons/hour. The system must overcome vacuum loss, prevent dust explosions, and integrate with an automatic bag unpacking machine. The customized solution uses a two-stage Roots pump in series and an intelligent vacuum regulating valve to ensure stable terminal pressure; a fully enclosed bag breaking device and a pulse dust removal system are designed to reduce dust concentration.

Paint Powder Vacuum Loading Machine Manufacturer

Our professional R&D team can customize vacuum loaders tailored to the specific requirements of the paint industry, such as explosion-proof, corrosion-resistant, and high-precision. We support material upgrades, including 316L stainless steel, explosion-proof design, expanded functionality, and intelligent integration. From automotive paints to food-grade paints, and from laboratory applications to large-scale production, we utilize modular design to shorten delivery cycles and rigorous testing to ensure equipment stability. We have served numerous companies.

In the paint production process, from inorganic pigments like titanium dioxide and talc to organic raw materials like resins and additives, traditional manual or mechanical conveying often faces challenges such as dust, moisture, and uneven mixing. Our Paint Powder Vacuum Loading Machine, with its core technology of "negative pressure closed conveying" and custom design tailored to the specific characteristics of paint raw materials, has become a key piece of equipment connecting all stages of paint production, ensuring clean and efficient material transportation while safeguarding paint quality.