Chemical Vacuum Loading System

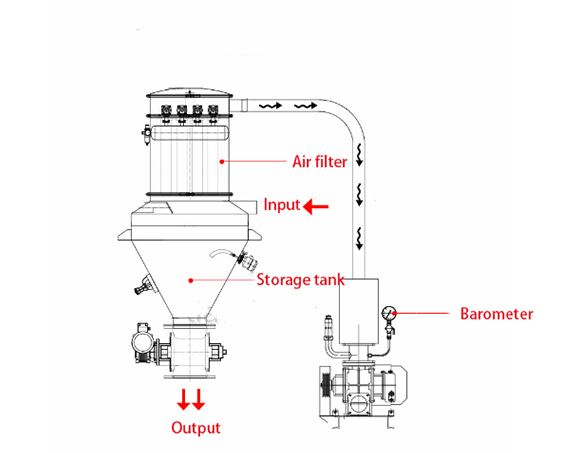

Chemical Vacuum Loading System utilizes negative pressure airflow generated by a vacuum pump as a power source. By creating airflow in a pipeline, it can suck materials from remote silos or bulk bags into a target container.

Belt Material: Stainless Steel

Voltage: 380V / Customizable

Application: Product Conveying

Frame Material: 304, 316 Stainless Steel/Carbon Steel

Capacity: 10 kg - 10 tons/hour

Length: Customizable, 1-100 meters

Filter: Stainless Steel Filter Element

Conveyed Materials: Granular and Powdered Products

Applicable Industries: Provides high-standard stainless steel vacuum loading solutions for various products in the chemical industry.

What is a Chemical Vacuum Loading System?

Chemical Vacuum Loading System core principle of the system is to use the negative pressure generated by a vacuum pump to draw materials such as powders and granules from storage containers into conveying pipes and precisely deliver them to the target equipment, ensuring a sealed and dust-free process. Compared to traditional mechanical conveying methods, this system offers advantages such as zero leakage, no cross-contamination, and strong adaptability. It is particularly suitable for automated production scenarios involving easily oxidizable, flammable, explosive, or high-purity materials. It provides an innovative solution for improving process stability, reducing labor costs, and offering different types of vacuum loaders to suit different chemical production scenarios.

What are the advantages of the Chemical Vacuum Loading System?

The Chemical Vacuum Loading System offers multiple core advantages to address the highly corrosive, flammable, explosive, and dust-prone characteristics of materials in the chemical industry, making it an upgraded alternative to traditional conveying methods.

Explosion-proof and corrosion-resistant: Material-contacting components are made of stainless steel, and the housing and electrical system meet explosion-proof standards. Equipped with an anti-static grounding device, this eliminates dust explosions and material corrosion risks at the source, making it suitable for conveying flammable and explosive materials such as sulfur powder and coal dust.

Material quality assurance: This prevents the entry of foreign matter into the conveying system, preventing cross-contamination of materials. It is particularly suitable for conveying fine chemicals with high purity requirements.

Flexibility: The system offers flexible layout and long conveying distances, allowing for easy navigation around obstacles and cascading multiple units to optimize production processes.

Customization: Special designs can be tailored to the characteristics of chemical materials. For example, nitrogen inerting, explosion-proof motors, and static elimination devices are used for explosive materials; and 316L stainless steel or special coatings are used for corrosive materials.

Chemical Vacuum Loading System Customization

Chemical production processes are complex and process variations vary widely. The Chemical Vacuum Loading System offers flexible customization to meet the needs of diverse scenarios.

Temperature and Wear Resistance: For high-temperature materials, the equipment seals are made of fluororubber resistant to temperatures exceeding 200°C, and the piping is constructed of thickened 316L stainless steel. For high-hardness particles, the piping is upgraded to a wear-resistant alloy to extend the equipment's service life.

Long-Distance and High-Lift Transportation: For long-distance or high-lift transportation across workshops, a high-negative-pressure vacuum pump can be configured with large-diameter piping, and flow guides can be installed at the piping inflection points to prevent material accumulation and blockage.

Multi-Material and Odor-Preventing Design: If the production line needs to alternately transport multiple chemical raw materials, a customized "multi-hopper switching system" can be used. Each hopper is dedicated to a specific material, and the hoppers and piping can be quickly disassembled and cleaned to prevent cross-contamination and odor transfer.

Automated Linkage Control: The equipment is equipped with a PLC control system that can be linked with equipment such as reactors and packaging machines on the chemical production line. Level sensors automatically monitor the material level in the hopper, enabling unmanned operation with automatic loading when low and automatic shutdown when full.

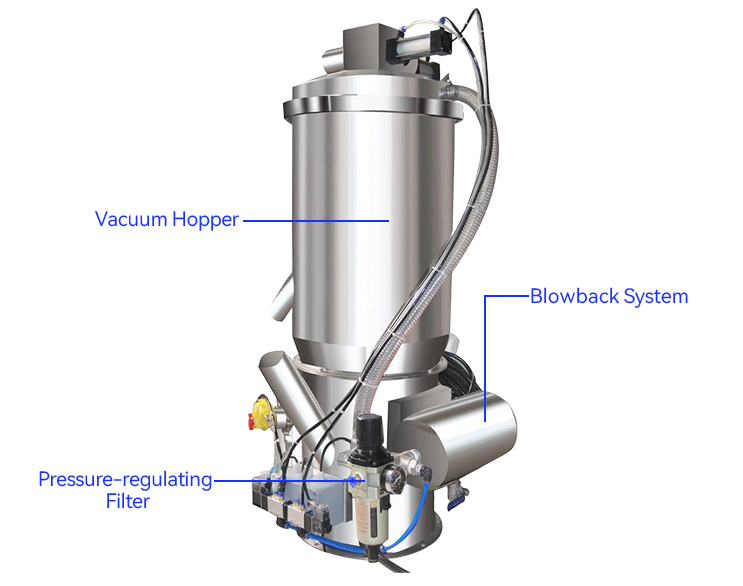

Chemical Vacuum Loading System Components

The core of the Chemical Vacuum Loading System consists of a vacuum generation system, corrosion-resistant conveying components, an air-material separator, and a PLC control system. These components are tailored to the characteristics of chemical materials and ensure stable conveying.

Vacuum Generation System:The core is an oil-free vacuum pump or generator, providing a stable negative pressure of -0.02 to -0.09 MPa to drive material conveying and prevent oil contamination of chemical materials.

Corrosion-Resistant Conveying Components:Includes 316L stainless steel/PTFE tubing and a custom suction nozzle. The polished interior prevents material residue and is resistant to acid and alkali corrosion.

Air-Material Separator:Comprising a separation hopper and a metal mesh/PTFE-coated filter element, the system efficiently separates material from air. The filter element is wear-resistant and easy to clean.

PLC Control System:Integrated material level and pressure sensors enable automatic start/stop, fault alarms, and can be linked with production line equipment.

Chemical Vacuum Loading System Technical Specifications

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

Chemical Vacuum Loading System Working Principle

The core principle of the Chemical Vacuum Loading System is based on the negative pressure environment created by a vacuum pump. When the system is activated, the vacuum pump draws air from the system through the pipeline, creating a vacuum state below the external atmospheric pressure. At this point, the powdered material in the storage silo or container is drawn into the conveying pipeline due to the atmospheric pressure difference, forming a gas-solid two-phase flow. At the end of the pipeline, the material is separated from the air flow by gravity or a backflush device, ultimately falling into the target equipment or storage container.

What chemical materials can be conveyed with the Chemical Vacuum Loading System?

The Chemical Vacuum Loading System, with its closed-loop conveying and wide adaptability, is widely applicable to the conveying of a variety of chemical materials. It can convey powdered, granular, flake, and mixed materials, and is particularly suitable for processes with strict environmental and safety requirements.

Powdered metal oxides: Conveying metal oxides such as red iron oxide, zinc oxide, aluminum oxide, and titanium dioxide are widely used in pigment coloring, catalyst carriers, and ceramic glaze preparation. For alkali metal compounds such as sodium carbonate, sodium bicarbonate, and sodium hydroxide flakes that require crushing before transport, the equipment uses closed pipes for dust-free feeding.

Granular chemical materials: The equipment supports continuous conveying of plastic granules such as PP, PE, and PVC, suitable for molding processes such as injection molding and extrusion. For SBR and NBR rubber granules, a temperature control system prevents adhesion caused by frictional heat during conveying, ensuring uniform feeding of recycled rubber powder.

Organic polymer materials: Powder coatings such as epoxy resin and polyester resin require strict static control during conveying. Chemical vacuum feeders use grounding devices and ionizing air wands to eliminate static electricity risks and prevent dust explosions. Thermoplastic elastomer (TPE) and TPU granules are transported using heated and insulated pipes to avoid pipe blockage caused by condensation.

Fine chemicals: The closed conveying system for powders such as disperse dyes and reactive dyes effectively prevents color cross-contamination, improving the quality of printed and dyed products. The conveying of pesticide intermediates such as glyphosate technical and pyridine compounds must comply with explosion-proof standards. The equipment utilizes nitrogen protection and a double mechanical seal design to ensure the safe transfer of flammable and explosive materials.

Flammable and explosive materials: For flammable and explosive materials such as aluminum powder and magnesium powder, the equipment utilizes nitrogen protection conveying technology, combined with an explosion-proof motor and static discharge device, to minimize explosion risks. The conveying of highly toxic substances such as phosgene precursors and sodium cyanide utilizes double mechanical seals and a negative pressure redundancy system for dual safety protection.

How does the Chemical Vacuum Loading System adapt to diverse conveying needs?

The Chemical Vacuum Loading System utilizes four core design features: customized material properties, adjustable conveying parameters, modular functional modules, and automated coordinated adaptation to precisely match the diverse material types and production scenarios of the chemical industry.

Customized Adaptation to Material Properties: Based on the differences in chemical material form and chemical properties, precise adjustments are made to the design, from core components to detailed details. For example, when conveying corrosive materials, contact parts are made of 316L stainless steel or polytetrafluoroethylene. When conveying high-temperature materials, fluororubber seals with a resistance of over 200°C are used. For high-hardness particles, the pipes are upgraded to wear-resistant alloys.

Flexible Adjustment of Conveying Parameters: Core equipment parameters can be adjusted based on production scale and conveying requirements. The vacuum pump power can be adjusted to match conveying capacities of 1 to 50 m³/h, meeting material transfers from a few kilograms to tens of tons. The pipe diameter and negative pressure can be adjusted to accommodate long-distance inter-plant conveying of 80 m or less and high-lift conveying of 30 m or less.

Combination and Adaptation of Functional Modules: Flexible functional modules can be stacked to meet specific needs. For example, when conveying multiple materials alternately, a "multi-hopper switching system" with a quick-cleaning interface is configured to prevent cross-contamination. When conveying moisture-sensitive materials, a pipe dehumidification module is installed to keep the materials dry.

Automated Linkage Adaptability: The device is equipped with a PLC control system and supports linkage with chemical production line equipment such as reactors, mixers, and packaging machines. Level and pressure sensors monitor operating conditions in real time, enabling unmanned operation with automatic loading for low material levels, automatic shutdown for full material levels, and automatic alarms for blockages.

Chemical Vacuum Loading System Customization Case Studies

We offer customers different conveying types and solutions tailored to specific business needs. We can tailor the optimal chemical vacuum loading system to suit specific production scenarios, ensuring smooth and high-speed production line operation.

New Energy Industry:When producing lithium iron phosphate cathode materials, companies needed to address metal contamination, excessive dust, and poor batch uniformity caused by manual shoveling. Our customized chemical vacuum loader, constructed of 316L stainless steel, integrates a molecular sieve drying system and an online cleaning module, enabling fully enclosed conveying throughout the entire process.

Food Industry:The company's previous use of a screw conveyor resulted in excessive metal residue and severe dust pollution in vitamin C powder. Our customized equipment, constructed of 304 stainless steel, is equipped with a bulk bag unloading station, a vibrating arch breaker, and a pulse backflush filter, ensuring fully enclosed, dust-free feeding. The quick-release piping design allows for complete disassembly and assembly by a single person in just 10 minutes.

Chemical Smelting:The sulfuric acid plant's existing pumping process faced issues such as pipe blockage, fire risks from leaks, and high manual inspection costs. The customized equipment adopts heat-resistant steel body, covered with aluminum silicate insulation layer, integrated steam jacketed piping and explosion-proof water ring vacuum pump to achieve stable transportation of molten sulfur.

Chemical Vacuum Loading System Manufacturer

Focusing on customer needs, we offer comprehensive solutions, from standard chemical vacuum loading systems to custom solutions. We support a variety of materials, including 304/316L stainless steel, carbon steel, and Teflon coatings, to meet specific operating requirements, including corrosion resistance, high-temperature resistance, and explosion-proof performance. The equipment seamlessly integrates with back-end equipment such as mixers, packaging machines, and reactors, and supports PLC intelligent control and data traceability, helping customers achieve enclosed conveying, dust-free production, and automated upgrades.

The Chemical Vacuum Loading System, with its high-speed, enclosed, and safe conveying method, perfectly solves many of the pain points in powder handling in the chemical industry. It is not only a key tool for improving production efficiency and achieving intelligent manufacturing, but also a significant embodiment of enterprises' commitment to safe production and environmental protection.