Lithium Battery Material Vacuum Loader

Lithium Battery Material Vacuum Loader addresses the challenges of dust leakage, oxidation deterioration, and cross-contamination during the transportation of ultrafine powders such as cathode ternary materials, anode graphite powder, and electrolyte additives.

Power: 1.5-5.5 kW (customizable)

Dimensions (L*W*H): Depends on the specific model

Material: 304/316 stainless steel

Voltage: 220V/380V/415V or customizable upon request

Customization: Acceptable

Type: neumatic/Electric/Continuous

Core Components: Motor, bearings, gears, pump, gearbox, engine

Applicable Materials: Graphite powder, electromagnetic materials, battery powder, lithium batteries, lithium battery powder, electromagnetic powder

What is Lithium Battery Material Vacuum Loader?

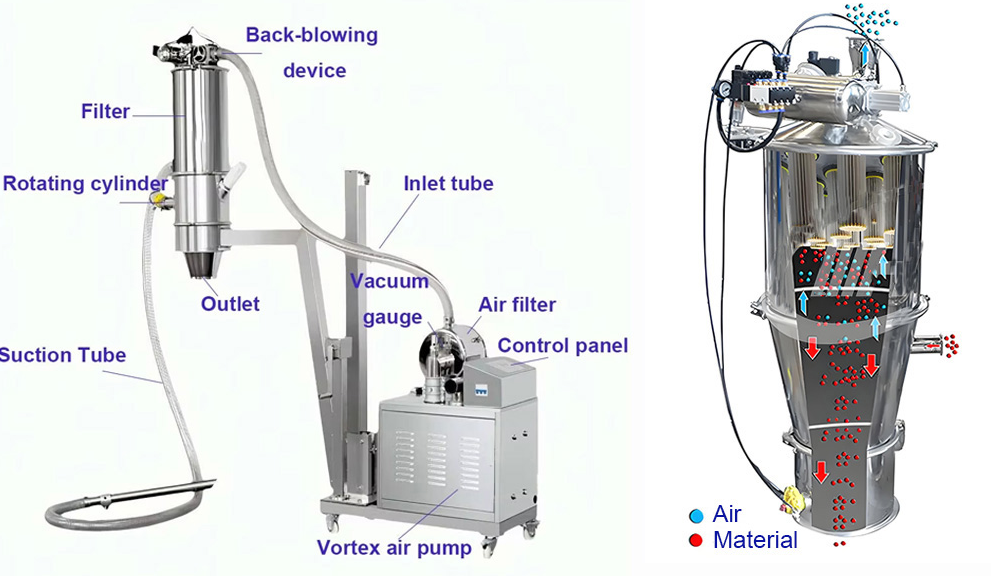

Lithium Battery Material Vacuum Loader is a closed automated conveying equipment designed by the lithium battery industry. It mainly solves the problems of dust leakage, oxidation and deterioration, and cross-contamination of ultrafine powders such as positive electrode ternary materials, negative electrode graphite powder, electrolyte additives and other ultrafine powders during transportation. It is powered by an oil-free vacuum pump, and forms a stable negative pressure in a closed system made of stainless steel, and drives material transportation by air pressure difference. It has the characteristics of anti-static, explosion-proof, and inert gas protection. It is a key equipment to ensure the purity and production safety of lithium battery materials.

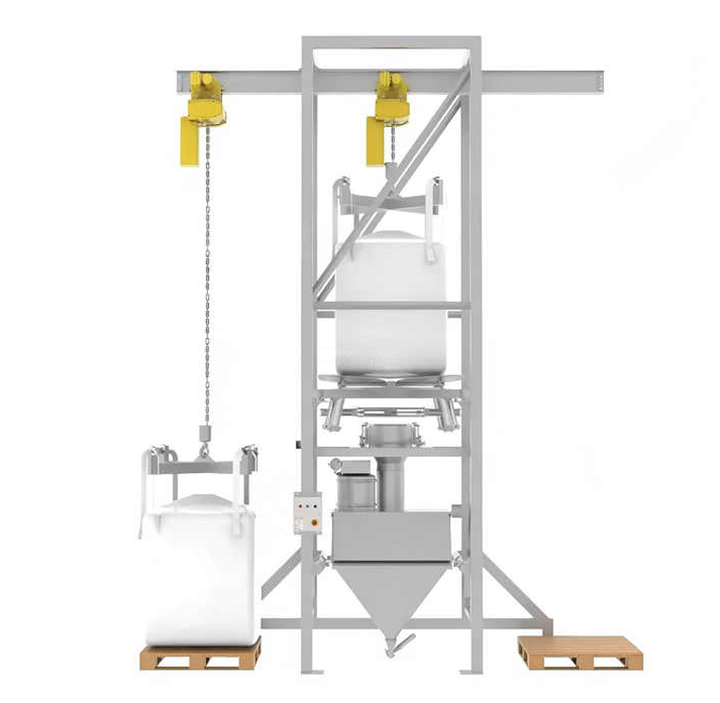

With its unique vacuum negative pressure technology, Lithium Battery Material Vacuum Loader breaks the limitations of traditional feeding methods in dust control, conveying efficiency and material adaptability. We can provide customers with different types of vacuum loaders of different materials, including fixed and mobile, to provide appropriate equipment for different production scenarios.

What are the types of Lithium Battery Material Vacuum Loader?

In the field of lithium battery material production, the safety and adaptability of material conveying equipment are extremely high. Explosion-proof and hand-cranked lithium battery material vacuum feeding machines have targeted solutions to key problems in lithium battery production with their unique design and functions, and have become an important type of equipment that has attracted much attention in the industry.

Explosion-proof Lithium Battery Material Vacuum Loader: With "multiple safety protection" to adapt to the flammable and explosive characteristics of lithium battery materials, the core is built with a solid safety line through triple design, complying with ATEX and IECEx standards, and eliminating electrical sparks; 316L stainless steel is used for metal parts such as pipelines and hoppers and are reliable grounded, and matched with flange jumpers to eliminate friction static electricity in time.

Hand-cranked lithium battery material vacuum feeding machine: with human power drive as the core, the piston/diaphragm reciprocating motion is driven by shaking the rocker to generate negative pressure, realizing material suction, gas separation and manual unloading. It does not require electricity/compressed air, and has significant advantages in scenarios such as power-free experimental sites and explosion-proof storage areas.

Why is a vacuum feeder a basic need for lithium battery production?

In lithium battery production, Lithium Battery Material Vacuum Loader has become a basic equipment. This is because the positive and negative electrode materials of lithium batteries are mostly expensive, fine and electrochemically active powders, and the traditional transportation method has serious defects: the mixing of foreign substances such as metal friction particles, dust, and dander will cause micro-short circuits inside the battery, threatening safety and life; rough transportation can easily cause layered material particle size or broken spherical particles, destroying the consistency of electrode coating, and deteriorating battery performance; residues when transporting different formula materials on the same production line will cause batch cross-contamination, causing product scrapping; and many battery materials are combustible, suspended dust can easily cause explosions, and some materials are also harmful to human health, and vacuum feeding machines can effectively avoid these risks.

Advantages of Lithium Battery Material Vacuum Loader

Lithium Battery Material Vacuum Loader is airtightly conveyed at negative pressure to prevent dust leakage and oxidation of materials such as ternary powder and graphite powder; supports customized fixed/mobile/lifting type, and is adapted to different production lines to ensure safety and purity.

Ensure battery quality: fully sealed conveying and anti-pollution design, avoid oxidation of lithium battery materials and impurities in mixing into them, and ensure material purity; accurate material level control and stable conveying volume to improve the consistency of lithium battery capacity, cycle life and other performance.

Reduce material loss: Anti-residue and material recycling design, reducing the loss rate of lithium battery materials from 5%-8% of traditional manual feeding to below 0.2%.

Improve safety environment: Anti-oxidation, anti-static, anti-dust leakage design, completely solve the safety hazards of traditional transportation, and avoid operators from directly contacting toxic and harmful lithium battery materials.

Anti-oxidation and static: The equipment adopts a "full-sealed inert gas protection" design, which can be filled with inert gas such as nitrogen to isolate the air from contact with lithium battery materials, avoiding oxidation and deterioration of easily oxidized materials such as graphite powder and ternary materials during the transportation process, and ensuring stable electrochemical performance of the battery.

Anti-blocking structure: In view of the characteristics that lithium battery materials are mostly ultra-fine powders and are prone to agglomeration, the suction nozzle adopts an anti-blocking design to reduce powder agglomeration through airflow optimization; the conveying pipeline adopts large diameter and large curvature elbows to reduce the flow resistance of powder in the pipeline.

How does Lithium Battery Material Vacuum Loader work?

The core principle of Lithium Battery Material Vacuum Loader is based on the negative pressure adsorption effect in fluid mechanics. The equipment forms a negative pressure environment in the closed hopper through a Roots fan or a vacuum generator, so that the lithium battery material in the storage silo is sucked into the conveying pipeline under the action of airflow, and finally falls into the target equipment accurately. This process is closed throughout the process and has no dust spillage, which not only avoids waste of materials, but also eliminates impurities that may be contaminated by manual operations.

What are the application scenarios of Lithium Battery Material Vacuum Loader?

Lithium battery production requires extremely high requirements for material purity, conveying sealing and automation. With its advantages of sealing, dust-free, precise and controllable, Lithium Battery Material Vacuum Loader has become the core conveying equipment in key processing processes.

Preparation of positive electrode material: In the mixing and sintering process of positive electrode material, the vacuum feeder assumes the core conveying function. For example, the dried positive electrode active material powder is transported from the silo to a high-speed mixer and mixed with conductive agents and binders in an accurate proportion.

Negative electrode material processing: In the refined processing process of negative electrode materials, vacuum feeding machines are mainly used at two key nodes: one is to transport the purified graphite powder from the graded equipment to the reactor in the coating process to ensure that the coating agent and graphite are uniformly combined; the other is to accurately transport the negative electrode powder to the stirring tank before mixing the finished negative electrode powder with the binder, and the feed volume is stably controlled by negative pressure.

Electrolyte and diaphragm auxiliary process: Although the electrolyte is liquid and the diaphragm is film-shaped, a vacuum feeder is indispensable in the transportation of its associated auxiliary materials. For example, during the raw material pretreatment stage of electrolyte preparation, solid powders such as lithium salts and additives can be transported to the liquid dispensing tank through a vacuum loader made of corrosion-resistant materials to seal the discharge tank to prevent the lithium salt from detachment in air.

Powder before battery cell assembly: vacuum feeder also plays an important role in the pre-mounting of pole sheets before battery cell assembly, battery cell shelling and other aspects. When preparing the electrode sheet, the rolled electrode sheet fragment can be transported to the crushing and recycling system through the equipment to realize material recycling and reduce production costs.

Lithium Battery Material Vacuum Loader+Cyclone Screen

The synergistic solution composed of Lithium Battery Material Vacuum Loader and cyclone screen is an efficient configuration for clean screening and transportation of lithium battery materials: the vacuum feeder sucks the positive electrode ternary powder, negative electrode graphite powder and other raw materials from the storage silo through stainless steel sealed pipes and transports them to the cyclone screen feed port; the cyclone screen uses centrifugal force and airflow to rotate the material at high speed, so that the qualified particle size powder is sieve, and impurities and agglomerated particles are discharged from the slag discharge port.

Lithium Battery Material Vacuum Loader Customer Cases

At a time when the lithium battery industry is booming, many companies are facing challenges in the lithium battery material transportation process. To overcome the difficulties, we have introduced Lithium Battery Material Vacuum Loader to many companies and achieved remarkable results.

High nickel ternary material dust-free conveying system: In view of the ultimate requirements of high nickel materials for metal pollution control, water isolation and material replacement cleaning, a fully stainless steel dust-free vacuum loading system is customized. The electropolishing material, nitrogen inertification protection and in-situ cleaning technology are used to achieve P foreign matter control, anti-oxidation throughout the process and rapid and residue-free cleaning.

Low-consumption explosion-proof delivery solution for nanoconductive agents: Develop a low-flow rate anti-static integrated screening system for carbon nanotube materials that are lightweight, easy to dust, easy to agglomerate and high explosion-proof requirements. Through Venturi soft wind transportation, integrated ultrasonic cyclone screen dispersed agglomerates and comprehensive explosion-proof design, the materials can be achieved while improving dispersion uniformity and fast charging performance, and completely eliminate the risk of dust explosion.

Lithium iron phosphate wear-resistant centralized conveying system: Design a heavy-duty wear-resistant centralized conveying system for the demand for strong wear and large-scale continuous production of lithium iron phosphate materials. Through ceramic wear-resistant elbows, replaceable wear-resistant linings and "one tow and multiple" high-power modular design, the equipment life is increased by 3 times and the maintenance cost is reduced by 40%.

Lithium Battery Material Vacuum Loader Manufacturer

We have been deeply engaged in the field of vacuum feeding machines for lithium battery materials for many years, have advanced production equipment and exquisite craftsmanship, and strictly follow international quality standards to build every equipment. Lithium Battery Material Vacuum Loader has advantages such as closed transport, precise and stable control, and easy maintenance and cleaning. It can be adapted to a variety of lithium battery materials to effectively solve problems such as dust pollution and low transportation efficiency. With a strong R&D team, we continue to innovate and continuously optimize product performance, and can customize production in combination with customer site and production needs.

Lithium Battery Material Vacuum Loader is a precision system integrating material protection, pollution control, production safety and intelligent management. Its wide application is an inevitable choice for lithium battery manufacturing to move towards high-end, large-scale and intelligent, and provides an indispensable basic guarantee for improving the energy density, cycle life and safety of the battery.