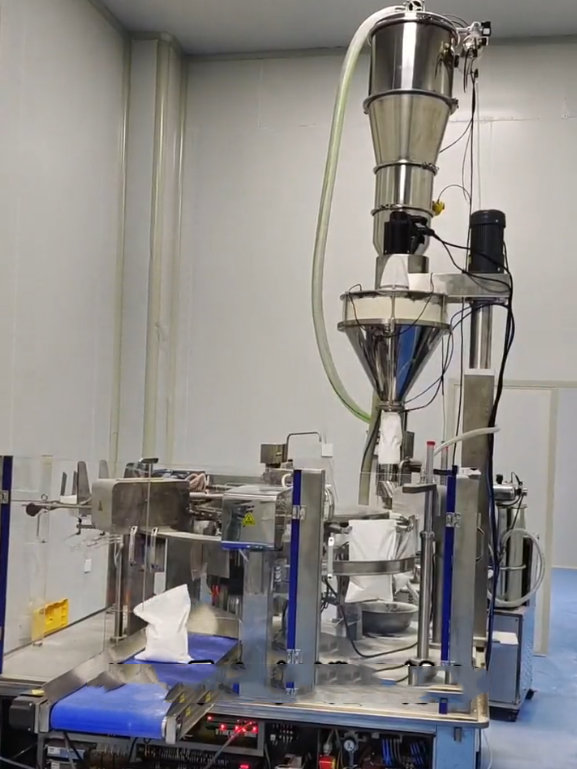

Hand lifting type vacuum feeder

Hand lifting type vacuum feeder is an innovative device that combines manual operation with vacuum conveying technology, designed for small and medium-sized batch material conveying scenarios.

Dimensions (length * width * height): 220*250*880/customizable

Features: antibacterial, easy to clean

Voltage: 380V, 110V, 220V, 440V, 480V, customizable

Function: material conveying

Machine type: liftable vacuum feeder

Thickness: 3-30 mm

Capacity: 100 kg - 20 tons/hour

Material: PU, rubber, stainless steel

Speed: adjustable, 20 m/min

Hose material: stainless steel, PVC

Applicable industries: food and beverage factories, farms, restaurants, homes, retail, food stores, construction projects, energy and mining industries, etc.

What is Hand lifting type vacuum feeder?

Hand lifting type vacuum feeder is an innovative device that combines manual lifting and vacuum adsorption, designed for laboratories, small production lines and special working conditions. No electric drive is required, and the material can be lifted to a height of 1.2-3 meters by manual crank. With the vacuum suction system, it can easily complete the dust-free conveying of powders and particles. The equipment is made of 304/316L stainless steel, compatible with a variety of containers such as ton bags and hoppers, and supports fast switching of different materials to avoid cross contamination.

Advantages of Hand lifting type vacuum feeder

The core features of the hand-cranked vacuum feeder are reflected in its unique human-machine collaborative design and flexible application performance.

Manpower drive and flexible lifting: The vacuum generating mechanism is driven by the hand-cranked device, and the height of the silo can be manually adjusted. It is suitable for different equipment stations and is equipped with a mobile base for easy movement in the workshop.

Compact and practical structure: The core consists of a piston/diaphragm vacuum mechanism, a stainless steel silo, a high-efficiency filter and a discharge valve, which occupies a small area and is easy to maintain.

Closed conveying: Materials are transported in a closed pipeline, equipped with a high-precision filter to prevent dust from spilling, meeting the hygiene requirements of the food, medicine and other industries.

Economical and low-consumption: No need for electric drive, extremely low energy consumption, purchase and maintenance costs are much lower than automated equipment, suitable for small and medium-sized batch production.

Wide material adaptability: It can transport powdered and granular materials, and can also reduce the loss of high-value or easily oxidizable materials through a vacuum environment.

Hand lifting type vacuum feeder composition structure

It uses a three-section stainless steel lifting column and a labor-saving gear set, with a vacuum suction system and a quick-release flange to achieve closed powder conveying without electric drive.

Vacuum generating mechanism: There are two common types: piston type and diaphragm type. The piston type realizes the change of chamber volume through the reciprocating motion of the piston in the cylinder to generate a vacuum; the diaphragm type uses the elastic deformation of the diaphragm to achieve the same effect.

Lifting system: The hand-cranked device drives the screw or chain to achieve the up and down movement of the silo. This design enables the equipment to flexibly adapt to receiving equipment of different heights. Whether it is a low mixing tank or a tall reactor, it can be accurately docked to complete material addition.

Silo and filter device: Generally made of stainless steel, it has good corrosion resistance and sturdiness and can adapt to various material characteristics.

Mobile base: To facilitate the movement of equipment in the workshop, the hand-cranked lifting type vacuum feeder is usually installed on a mobile base with rollers. The rollers generally have good wear resistance and steering flexibility, and some also have brake functions to fix the equipment after reaching the working position.

Working principle of hand lifting type vacuum feeder

The working principle of the hand-cranked lifting type vacuum feeder revolves around human drive and vacuum negative pressure. The operator shakes the rocker to drive the piston or diaphragm mechanism in the equipment to reciprocate, so that the volume of the sealed chamber changes periodically, and negative pressure is formed when the volume increases. This vacuum state is transmitted through the suction pipe and suction nozzle. Under the action of atmospheric pressure, powdered or small particles are sucked in and sent to the silo. After the material and air mixture flows into the silo, the material falls due to gravity, and the air is purified and discharged through the top filter. After the suction is completed, the discharge valve at the bottom of the silo is manually opened, and the material falls into the target container by gravity. After closing the valve, the next suction cycle can be started.

Specifications

|

Model |

Motor Power (KW) |

Conveying Capacity (Koh) |

|

HCSL - 1 |

1.5 |

400 |

|

HCSL - 2 |

2.2 |

600 |

|

HCSL - 3 |

3 |

1200 |

|

HCSL - 4 |

5.5 |

2500 |

|

HCSL - 6 |

5.5 |

3200 |

|

HCSL - 7 |

7.5 |

6000 |

|

HCSL - 10-6 |

7.5 |

6000 (When the conveying distance is 10 meters) |

|

HCSL - 20-5 |

11 |

5000 (When the conveying distance is 20 meters) |

What is the lifting height of the hand-cranked vacuum loader?

The lifting height of the hand-cranked vacuum loader usually varies according to the model and design. The following is a detailed parameter description.

The standard lifting height of the hand-cranked vacuum loader is 1.2-3 meters: it can meet the needs of most production scenarios, such as lifting the floor material barrel to the 1.5-meter high mixer feed port, or conveying the pallet material to the 2.2-meter high packaging machine, and a single lifting takes only 15-30 seconds.

The maximum lifting height of the extended model can reach 5 meters: but it needs to be equipped with a reinforced chain drive system and follow safety restrictions. When it exceeds 3 meters, the load must be ≤20kg, and a fixed bracket must be installed to prevent shaking. Special customized models can be adapted to 4-5 meters high operations.

Targeted recommendations for different scenarios: Laboratory operations prefer 1.2-1.8 meters in height to match the biosafety cabinet; standard production lines are suitable for docking reactors in the range of 2-3 meters; special high-level operations require customized 4-5 meters solutions. All models are equipped with safety card slots for positioning, and it is recommended to use them strictly according to the load-bearing curve (≤30kg within 3 meters, ≤20kg for 3-5 meters).

In what scenarios are hand-cranked vacuum loaders generally used?

The hand-cranked vacuum loaders are particularly outstanding in the following six typical scenarios due to their non-power dependence and flexible operation.

Laboratory R&D precision assistant: In response to the transfer needs of small batches (5-20kg) of high-value materials, the hand-cranked vacuum loaders use closed transportation to avoid the risk of dust exposure caused by manual dumping, especially for sensitive materials such as API raw materials. Its fast material replacement and cleaning design effectively prevents cross contamination and supports operations in closed spaces such as glove boxes.

Small production line efficiency tool: In the process of batching, packaging, feeding, etc., the hand-cranked vacuum feeder can accurately connect to the equipment feed port, and can easily handle sticky materials with the vibration auxiliary module.

Special environment application expert: Faced with special working scenarios, this equipment shows strong adaptability. In explosion-proof areas, it has passed ATEX Zone1 certification with its design without electrical components, and safely conveys solvent-based powders.

Flexible production and efficient solution: To meet the production needs of multiple varieties, the hand-cranked vacuum feeder can quickly switch materials within 5 minutes and avoid mixing through the color identification system.

What equipment can the hand-cranked vacuum feeder be used with?

The hand-cranked vacuum feeder can be used with a variety of equipment through flexible interface design to form a complete material conveying system.

Mixing/mixing equipment: The hand-cranked vacuum feeder can be seamlessly connected to V-type mixers, ribbon mixers and other equipment, and leak-proof docking is achieved through DN80/DN100 quick-release flanges and magnetic sealing rings. Its precise feeding control (error ±1%) completely solves the dust problem of manual feeding.

Intelligent upgrade solution for packaging system: When the equipment is matched with valve bag packaging machine, ton bag packaging station, etc., a weighing module with ±10g accuracy and a flexible telescopic tube can be installed to achieve multi-station adaptive filling.

Integrated screening and detection: In the material fine processing link, it can form a joint operation unit with a vibrating screen and a metal detector. The transparent observation window design monitors the conveying status in real time, the modular quick-disassembly structure is convenient for cleaning and maintenance, and the integrated design of airflow screen and vacuum feeding saves 30% of space.

Hand lifting type vacuum feeder price

The price of the hand-cranked lifting vacuum feeder varies due to differences in configuration and function, mainly affected by the following factors: the use of materials such as 304 or 316L stainless steel will affect the cost; the difference in lifting height from basic models to extended models; whether to select additional functions such as weighing modules and explosion-proof devices; and the difference between different brands and after-sales service levels. This model has a significant cost advantage over electric models, especially suitable for small and medium-sized enterprises with limited budgets but need to avoid manual handling. The basic model for laboratory use is usually positioned as more economical, while the industrial explosion-proof model is positioned in the middle and high end. Although the initial investment of the equipment is low, it can greatly reduce the long-term labor cost. Most users report that the investment can be recovered in a relatively short time. The specific quotation needs to be evaluated according to the material characteristics, conveying volume and supporting needs of the actual application. You can leave a message in our background to get the latest price parameter table!

The hand-cranked lifting vacuum feeder provides an innovative solution for powder material conveying with its high speed, environmental protection and flexibility. In the wide application of food, medicine, chemical and other industries, it not only improves production efficiency, but also reduces environmental pollution and labor costs. With the continuous advancement of technology, this equipment will demonstrate its value in more fields and promote the coordinated development of industrial automation and green manufacturing.