Vibratory Sieving Machine

It can be used for screening, peeling, dust removal, filtering and grading of powder, granules and liquid materials, and can achieve 5 different grading in one operation

Screening mesh: Within 500 mesh (25 microns)

Output: 1-5 tons/hour

Material: Carbon steel, carbon steel + stainless steel, all stainless steel, plastic

Customization: Ultrasonic, edge-added, gate-type, silo-type, mobile

Screening materials: Starch, soybean milk, soy sauce, MSG, resin powder, paint, Chinese medicine powder, electromagnetic materials, plastic particles, washing powder, etc.

What is Vibratory Sieving Machine?

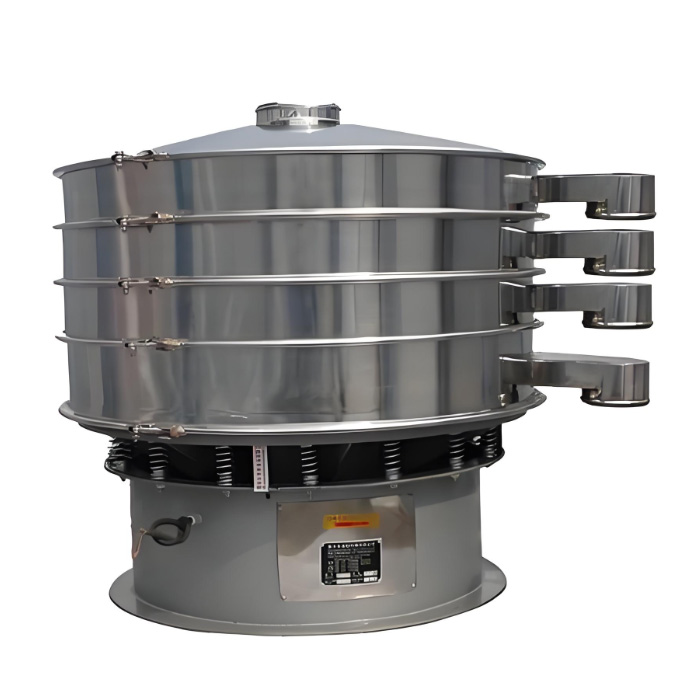

Vibratory Sieving Machine, also known as three-dimensional vibrating screen, is a high-precision fine powder screening machine that can be used for screening, impurity removal, filtration and classification of powder, granules and liquid materials. It can achieve 6 different classifications in one operation. The closed design can prevent harmful dust or smoke leakage. It provides various sizes from 400mm to 2000mm diameter, and can also be specially customized. There are 3 materials: carbon steel, 304 stainless steel and plastic anti-corrosion.

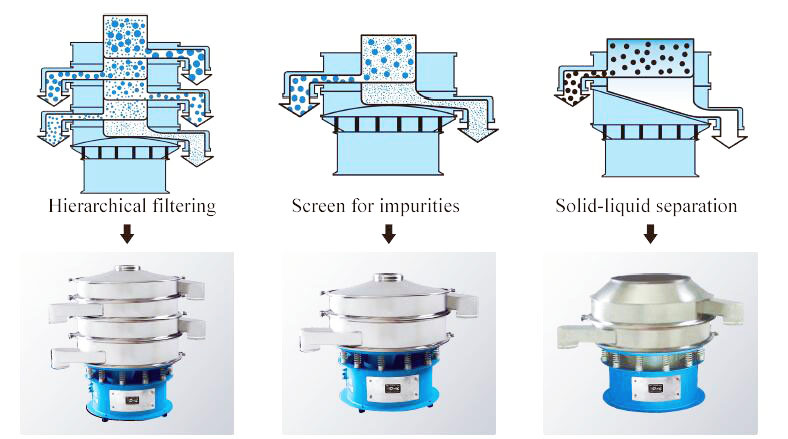

What are the functions of Vibratory Sieving Machine?

Vibratory Sieving Machine can be used for screening, filtering and impurity removal of powder, granules and liquid materials.

Grading (multi-layer): divide powder/granules into 2-5 grades, with a grading accuracy of 95%;

Impurity removal (single layer): filter and remove agglomerates or unqualified materials in the material, with an impurity removal accuracy of up to 98%.

Filtration (single layer): remove particles/foreign matter in liquid materials, with a filtration capacity of 5t/h

What types of Vibratory Sieving Machine are there?

Vibratory Sieving Machine materials can be divided into 4 types: carbon steel, stainless steel for the material contact part, all stainless steel, and plastic. Users need to choose according to the material characteristics and actual needs. This series of rotary vibrating screens can be used for single-layer impurity removal, multi-layer grading, and solid-liquid separation and filtration. The number of screen layers is 1-5, and 2-6 levels of sorting and filtration can be performed simultaneously. The screening accuracy is high and the applicable material range is wide.

What are the advantages of Vibratory Sieving Machine?

Vibratory Sieving Machine can handle powder particles within 500 mesh and 5-micron slurry materials. Each device can be equipped with 1-5 layers of screens, and 2-6 levels of sorting or filtration can be achieved at the same time. Its unique bouncing ball cleaning device effectively prevents blockage by continuously hitting the screen, ensuring that the material is automatically discharged and there is no residue in the machine, which greatly improves the screening output and efficiency. The fully sealed structure design eliminates dust flying and liquid leakage, meeting environmental protection production requirements. In addition, the equipment adopts a parent-child mesh structure frame to ensure the flatness and tension of the screen, which can not only prevent the material impact from collapsing the screen, but also avoid the bouncing ball from damaging the working net. It only takes 3-5 minutes to change the net, which is easy to maintain and simple to clean, significantly extending the service life and reducing operation and maintenance costs.

How does the Vibratory Sieving Machine work?

The Vibratory Sieving Machine uses an upright motor to drive the upper and lower eccentric blocks to rotate, generating multi-dimensional vibrations (up and down, left and right, front and back). This vibration allows the material on the screen to spread outward in a spiral shape. By adjusting the angle of the eccentric block, the movement of the material can be controlled to achieve screening of different precisions. It's like shaking your wrist when sifting flour with a sieve, but it's smarter and more efficient, and can be finely sorted and quickly graded.

Vibratory Sieving Machine Parameters

| Model | Screen surface diameter (mm) | Processing capacity (tons/hour) | Power (kW) | Screening layer number | Applicable foam type |

| DHC-600 | 600 | 0.5-1.5 | 0.25 | 1-3 | EPS recycling pellets |

| DHC-800 | 800 | 1.2-2.5 | 0.55 | 1-3 | EVA foam particles |

| DHC-1000 | 1000 | 2-4 | 0.75 | 1-4 | PP packaging foam |

| DHC-1200 | 1200 | 3-6 | 1.1 | 1-5 | PU insulation foam |

| DHC-1500 | 1500 | 5-8 | 2.2 | 1-5 | Mixed recycled foam |

| DHC-1800 | 1800 | 6-10 | 3.0 | 1-5 | Large foam crushing |

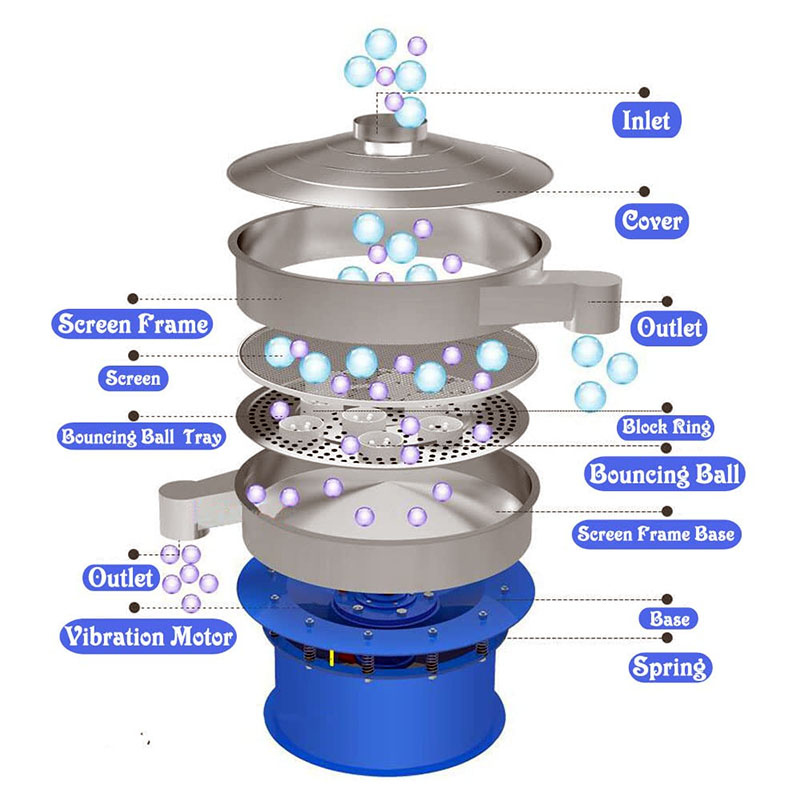

What are the structures of the Vibratory Sieving Machine?

The Vibratory Sieving Machine consists of a feed port, a dust cover, a discharge port, a tie ring, a screen, a counterweight, an upper weight, a vibrating body, a vibrating motor, a spring, a lower weight, a machine base, and other parts.

Dust cover: prevents the material from spreading outward, and can also protect external dust from entering, thereby contaminating the screened material.

Tie ring: used to fix the screen frame part in the middle of the screen body.

Upper weight and lower weight: Changing the phase angle of the upper and lower weights of the vibration motor can change the movement trajectory and residence time of the material on the screen.

Spring: Vibration reduction and sound insulation.

Base: Support the entire vibrating screen to keep it stable.

What are the applications of Vibratory Sieving Machine?

Vibratory Sieving Machine is widely used in many industries: in the food industry, it can screen starch, sugar powder, coffee powder, glutinous rice flour, soybeans, corn, peanuts, sesame and other raw materials and soy milk, vinegar and other liquid materials; in the pharmaceutical industry, it is suitable for the classification of Chinese medicine powder, medicine, vitamins and other pharmaceutical products; in the chemical industry, it can process pigments, washing powder, paint, soda ash, lemon powder, resin powder, plastic and other chemical raw materials; in the abrasive ceramic industry, it can effectively screen aluminum oxide, quartz sand, mud, spray soil particles and other materials; in the metallurgical industry, it can be used for the screening of titanium oxide, zinc oxide, electromagnetic materials, metal powder, welding rod powder and other metal materials; in the papermaking industry, it is suitable for the processing of papermaking raw materials such as coatings, clay mud, black and white liquid, waste liquid, papermaking liquid, etc., to meet the different screening needs of various industries.

| Material | Sieve (mesh/inch) | Processing capacity (kg/hour) |

| Milk powder | 16.2 | 2000 |

| Sugar | 4.2 | 5000 |

| Salt | 30/80 | 5000 |

| Chinese medicine pesticide | 80/100/150 | 1400 |

| Chinese medicine powder | 80 | 550 |

| Electric jade powder resin DV | 40/60/80 | 1000 |

| Grinding powder | 40/60/250 | 1200 |

| Pigment powder | 20 | 4000 |

| Graphite | 16/40/80 | 1400 |

| Iron powder | 60/80/120 | 2500 |

| Copper powder | 80 | 2000 |

| Copper powder | 40/65/200 | 2000 |

| Aluminum silver powder | 60 | 1500 |

| Starch | 80 | 1200 |

| Activated carbon | 40/60 | 1000 |

| Paint | 100 | 7500 |

| Carborundum | 60 | 300 |

Sieve For Polystyrene Pellets

Sieve For Polystyrene Pellets Foam Screening Machine

Foam Screening Machine Solid Liquid Separation Equipment

Solid Liquid Separation Equipment Ultrasonic Sieve

Ultrasonic Sieve