Electrolytic gold extraction machine

Designed specifically for gold extraction, it is designed to efficiently recover gold from electronic waste, jewelry scrap and industrial by-products.

Price: $800-$20,500

Recovery Rate: Up to 99.5%

Capacity: 100-800L

Voltage: 220V/380V

Motor power: 1.5-5.5kw

What is Electrolytic gold extraction machine?

Our electrolytic gold extraction machines utilize the principle of electrolysis to selectively deposit gold from a gold-bearing solution onto a cathode. This process allows for the highly efficient separation and purification of gold, resulting in a final product with remarkable purity. Our machines are built with robust materials and incorporate advanced control systems to ensure stable and reliable operation. We offer a variety of models with different capacities and features to cater to the specific needs of our clients.

What are the advantages of Electrolytic gold extraction machine?

Electrolytic gold extraction machine achieves high-purity and high-efficiency gold recovery through electrolytic technology, with low energy consumption, simple and safe operation interface, and you can choose the equipment of appropriate capacity according to the application scenario.

High Gold Purity: Achieve gold purity levels of up to 99.99% or higher, meeting the most stringent industry standards.

High Recovery Rate: Our optimized electrolytic process ensures maximum gold recovery from the input solution, minimizing losses.

Environmentally Friendly: Electrolytic extraction is a cleaner and more environmentally sound alternative to traditional chemical methods, reducing the use of hazardous substances.

Cost-Effective Operation: Lower energy consumption and reduced chemical usage translate to significant operational cost savings.

Safe and Reliable: Our machines are designed with safety features and robust construction for long-term, reliable operation.

User-Friendly Interface: Intuitive control systems and easy maintenance design simplify operation and minimize downtime.

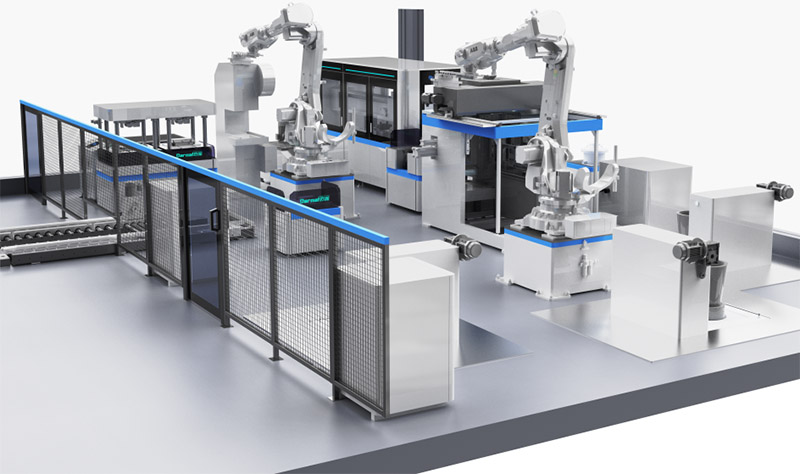

Scalable Solutions: We offer machines with varying capacities to suit small-scale operations as well as large industrial applications.

Direct from Manufacturer: Benefit from competitive pricing, direct technical support, and customized solutions tailored to your specific requirements.

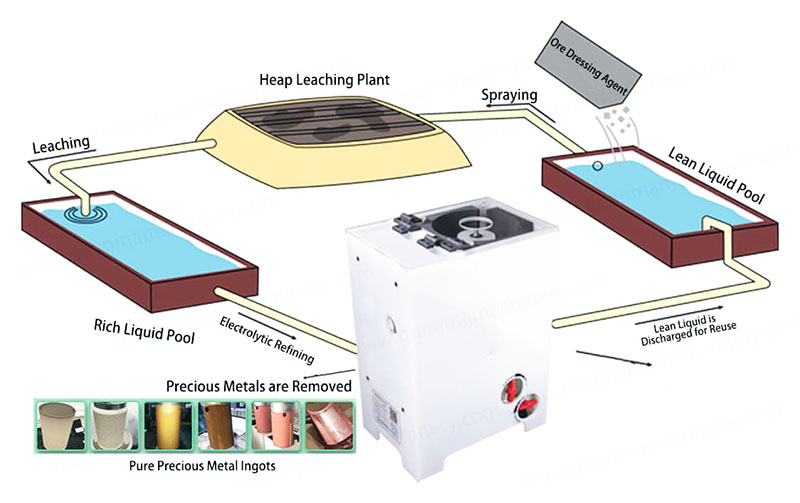

What is the process flow of Electrolytic gold extraction machine?

The electrolytic gold extraction process involves passing a controlled electric current through an electrolyte solution containing dissolved gold ions. This solution is typically derived from leaching processes (e.g., cyanide leaching, thiosulfate leaching) or the dissolution of gold-containing materials.

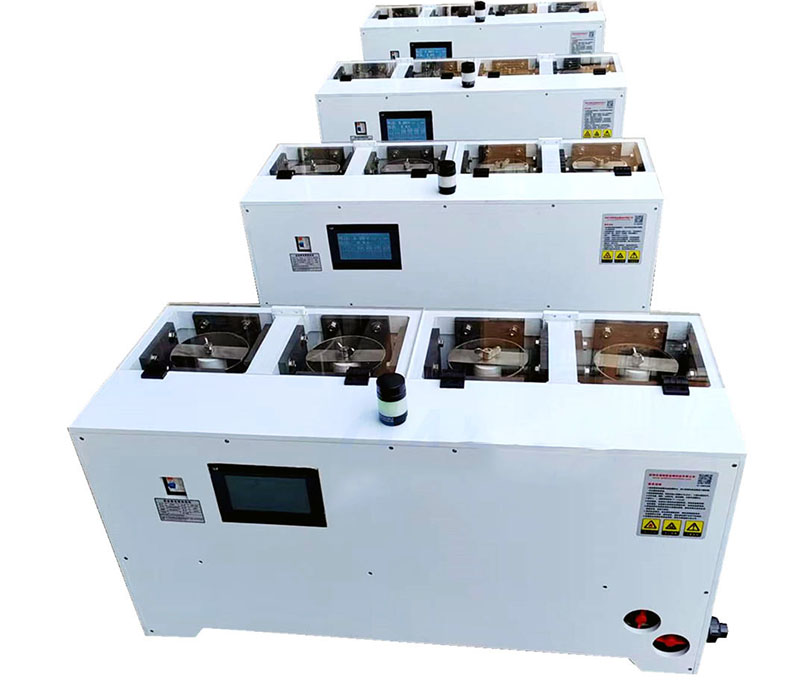

Electrolytic gold extraction machine parameters

| Model | Product Name | Specifications (mm) | Rated Voltage | Power | Weight (kg) |

| JQ-DJC-L1 | Cyclone Plating Tank | 450*300*600 | 380V | 1.5KW/H | 45 kg |

| JQ-DJC-L3 | Cyclone plating tank | 1140*1010*800 | 380 volts | 4KW/H | 135 kg |

| JQ-DJC-L4 | Cyclone plating tank | 1520*1010*800 | 380 volts | 5.5KW/H | 180 kg |

What are the applications of Electrolytic gold extraction machine?

Our Electrolytic Gold Extraction Machines are ideal for a wide range of industries and applications, including:

E-waste Recycling Facilities: Efficiently recovering gold from electronic scrap.

Jewelry Refineries: Refining gold from jewelry waste and scraps.

Electroplating Companies: Reclaiming gold from spent plating solutions.

Small-Scale Mining Operations: Enhancing gold recovery from concentrates.

Research and Development: For precious metal recovery and purification studies.

Investment Casting: Recovering gold from casting residues.

Electrolytic gold extraction machine Customer Case

E-waste Recycling Plant in Southeast Asia: A large-scale e-waste recycling facility implemented our 2000L batch electrolytic gold extraction machine. They achieved a gold recovery rate of over 99% from their cyanide leaching solution, producing 99.95% pure gold and significantly reducing their reliance on traditional smelting methods.

Small-Scale Mining Operation in South America: A small gold mining operation adopted our 500L electrolytic cell for processing their thiosulfate leach liquor. They were able to efficiently recover high-purity gold on-site, eliminating the need for costly and time-consuming off-site refining.

Jewelry Recycling Business in Europe: A jewelry recycling company utilized our 100L electrolytic gold extraction machine to recover gold from their scrap jewelry and polishing residues. The compact and user-friendly design allowed them to efficiently refine gold to 99.99% purity within their workshop.

Why Choose Our Electrolytic Gold Extraction Machines?

As a direct manufacturer, we offer not only high-quality and innovative electrolytic gold extraction machines but also comprehensive technical support, competitive pricing, and customized solutions to meet your specific gold recovery needs. Our commitment to excellence and customer satisfaction makes us your trusted partner in gold refining.