Industrial NOx Waste Gas Treatment Equipment For PGM Refinery

Provide industrial nitrogen oxide (NOx) waste gas treatment solutions for platinum group metal (PGM) refineries to effectively reduce nitrogen oxide (NOx) emissions in precious metal refining processes.

Price: $500-$30,000

High-efficiency NOx removal (up to 98% reduction)

Custom-designed for PGM refinery gas compositions

Robust construction for corrosive refinery environments

What is Industrial NOx Waste Gas Treatment Equipment For PGM Refinery?

Industrial NOx Waste Gas Treatment Equipment For PGM Refinery is designed specifically for platinum group metal (PGM) refineries to meet the unique challenges of nitrogen oxide emissions from processes such as nitric acid leaching and aqua regia dissolution. Our equipment uses a multi-stage jet wet gas scrubbing system to ensure efficient and compliant removal of nitrogen oxides, protecting the environment while ensuring the output of precious metals.

What are the advantages of Industrial NOx Waste Gas Treatment Equipment For PGM Refinery?

High purification efficiency: NOx removal rate exceeds 95%, ensuring emissions meet strict environmental standards.

Customized multi-stage design: Customize the number of stages and reagents according to specific exhaust gas characteristics to optimize treatment effects.

Compact footprint: Efficient space design, suitable for various facility layouts without compromising performance.

Acid mist recovery: The integrated gas-liquid separator condenses and returns the acid mist to the reactor, reducing acid consumption and precious metal loss.

Advanced oxidation process: The buffer tank equipped with bubbling nozzles enhances gas-liquid contact and effectively converts NO to NO₂.

Efficient jet scrubbing: The jet tower equipped with dynamic wave nozzles and ball ring packing ensures sufficient gas-liquid interaction to maximize NOx absorption rate.

Real-time monitoring: Built-in pH and temperature sensors can maintain optimal reaction conditions to ensure stable performance.

What is the working process of Industrial NOx Waste Gas Treatment Equipment For PGM Refinery?

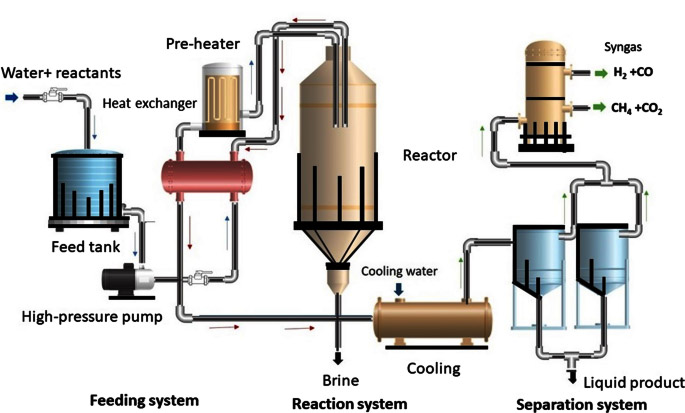

The system operates in the following sequence:

Condensation: The hot NOx-rich gas passes through a gas-liquid separator, which condenses the acid mist and returns it to the reactor.

Oxidation: In the buffer tank, the oxidant converts NOx into NO₂, and bubble nozzles enhance the gas-liquid contact.

Jet scrubbing: The oxidized gas enters the jet tower, where it interacts with the urea solution, converting NO₂ into harmless nitrogen, CO₂ and water.

Final purification: The spray and packing layers in the tower ensure that any remaining NO₂ is absorbed, with a purification efficiency of more than 80% per stage.

What are the applications of Industrial NOx Waste Gas Treatment Equipment For PGM Refinery?

PGM Refineries: Effective treatment of NOx emissions during platinum, palladium, and rhodium refining processes.

Gold & Silver Electrolysis: Mitigates NOx emissions in precious metal electrolysis operations.

Chemical Laboratories: Suitable for facilities handling nitric acid and related compounds.

Mining & Metallurgy: Addresses NOx emissions from various metallurgical processes.

Industrial NOx Waste Gas Treatment Equipment For PGM Refinery Customer Case

1. Large platinum group metal refinery in South Africa

Installed capacity: 120,000 Nm3/h, inlet NOx: 2,800 mg/Nm3, outlet NOx: 45 mg/Nm3, 24/7 operation from 2022, 22% lower reagent cost compared to traditional SCR

2. North American platinum recovery facility

Customized solution for intermittent operation, comprehensive control of NOx and acid gases, NOx removal efficiency up to 97%, zero wastewater discharge

3. Expansion of palladium refinery in Russia

Transformation of existing gas treatment system, 40% increase in capacity, NOx concentration maintained below 50 mg/Nm3, payback period of less than 2 years