2-3min Induction Gold Melting Furnace Silver Copper Induction Heating Furnace

Highly efficient heating equipment for rapid melting of gold, silver and copper

Price: $450-$120,000

Maximum temperature: 1600℃

Dissolving time: 2-3 minutes

Metal capacity: 1-4 kg (gold)

Applicable metals: gold, K gold, silver, copper, brass and its alloys

What is 2-3min Induction Gold Melting Furnace Silver Copper Induction Heating Furnace?

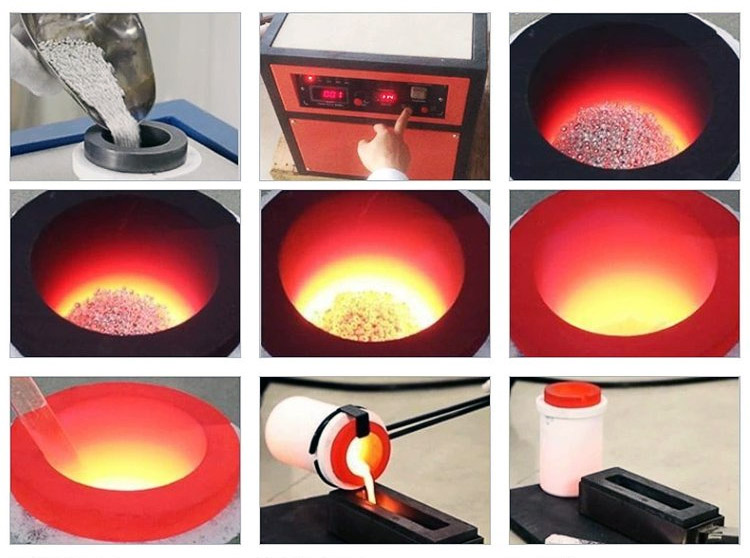

2-3min Induction Gold Melting Furnace Silver Copper Induction Heating Furnace adopts advanced IGBT induction heating technology, which can quickly melt precious metals such as gold (Au), silver (Ag), copper (Cu), zinc (Zn) in 1-3 minutes. It is suitable for jewelry processing, precious metal recycling, precision casting and other industries.

Compared with traditional furnaces, our equipment saves 15-30% energy and supports 2-10kg melting capacity to meet production needs of different scales.

What are the advantages of 2-3min Induction Gold Melting Furnace Silver Copper Induction Heating Furnace?

2-3min Induction Gold Melting Furnace Silver Copper Induction Heating Furnace can achieve ultra-fast melting of metal in 2-3 minutes, with low energy consumption, precise temperature control, and full-automatic operation, which is simpler and suitable for melting a variety of metals

Ultrafast smelting: 1-3 minutes to complete metal melting, improve production efficiency.

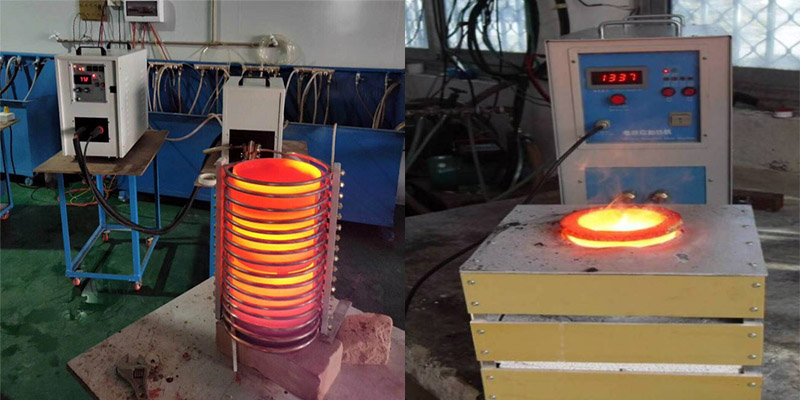

Energy-saving and high efficiency: Compared with traditional KGPS furnaces, it saves 15-30% energy and reduces operating costs.

Accurate temperature control: Adopting PID intelligent temperature control system, the temperature can reach 1800°C to avoid metal oxidation.

Safe and stable: Fully enclosed water cooling system to prevent overheating damage and extend equipment life.

Easy operation: One-button start, automated smelting process, and reduced manual intervention.

Multi-functional application: Applicable to gold, silver, copper, aluminum, brass, bronze and other metals.

What is the principle of 2-3min Induction Gold Melting Furnace Silver Copper Induction Heating Furnace?

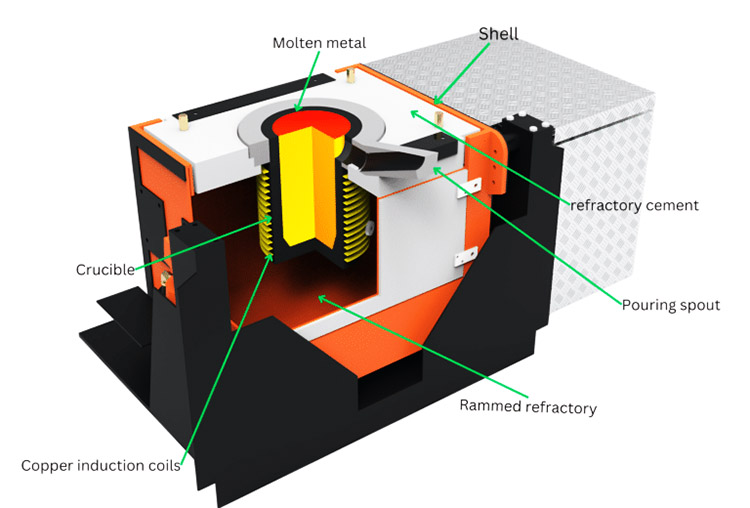

Our induction melting furnace is based on the principle of electromagnetic induction heating:

High-frequency alternating current generates an alternating magnetic field through an induction coil.

Metals (gold, silver, copper) generate eddy currents in the magnetic field and melt due to resistance heating.

Vacuum/inert gas protection prevents metal oxidation and ensures smelting purity.

2-3min Induction Gold Melting Furnace Silver Copper Induction Heating Furnace Parameter

| Model | HJ-1106A | HJ-1106B | HJ-1106C | HJ-1106D |

| Power (kW) | 8 | 10 | 12 | 15 |

| Voltage (V) | 380V, 50/60Hz | 380V, 50/60Hz | 380V, 50/60Hz | 380V, 50/60Hz |

| Smelting capacity (kg) | 4kg | 6kg | 8kg | 10kg |

| Maximum temperature (°C) | 1500-1800°C | 1500-1800°C | 1500-1800°C | 1500-1800°C |

| Smelting time (min) | 2-4 | 2-4 | 2-4 | 3-5 |

| Cooling method | Water cooling / chiller | Water cooling / chiller | Water cooling / chiller | Water cooling / chiller |

What are the applications of 2-3min Induction Gold Melting Furnace Silver Copper Induction Heating Furnace?

2-3min Induction Gold Melting Furnace Silver Copper Induction Heating Furnace can be used for melting various precious metals in industries such as jewelry manufacturing, precious metal recycling, investment casting, and laboratory research.

Jewelry manufacturing: smelting gold, silver, and platinum for jewelry casting.

Precious metal recycling: efficient recycling of gold, silver, and copper from scrap electronics and industrial waste.

Investment casting: suitable for small metal parts, dental alloys, electronic components.

Laboratory research: used by universities and research institutions for new material development and metal purification.

2-3min Induction Gold Melting Furnace Silver Copper Induction Heating Furnace Customer Case

A jewelry processing factory – After using HJ-1106C (12kW), production efficiency increased by 40% and gold loss decreased by 15%.

Precious metal recycling company – Using HJ-1106D (15kW) to process 50kg of waste materials per day, saving $10,000+ in electricity costs per year.

University materials laboratory – used for nano-gold particle research, with a smelting purity of 99.99%.