Multistage Jet Waste Gas Treatment Equipment High Concentration Nitrogen Oxide

Achieves over 95% NOx removal, reducing emissions from concentrations as high as 20,000 ppm to below 150 ppm.

Price: $600-$80,000

Inlet concentration: Can treat nitrogen oxide waste gas with a concentration of up to 40,000 mg/m³

Outlet concentration: After treatment, the nitrogen oxide concentration in the waste gas can be reduced to less than 50 mg/m³

What is Multistage Jet Waste Gas Treatment Equipment High Concentration Nitrogen Oxide Removal?

The Multistage Jet Waste Gas Treatment Equipment High Concentration Nitrogen Oxide Removal is a cutting-edge solution designed for industries dealing with high concentrations of nitrogen oxide (NOx) emissions, such as power plants, chemical plants, metallurgical plants and waste incineration plants.

The system uses multi-stage jet absorption technology to effectively neutralize NOx, ensuring compliance with strict environmental regulations (e.g. EPA, EU standards) while minimizing operating costs.

What are the advantages of Multistage Jet Waste Gas Treatment Equipment High Concentration Nitrogen Oxide Removal?

High Removal Efficiency: Achieves 95%+ NOx elimination even at high concentrations (up to 5000 mg/m³).

Low Energy Consumption: Optimized jet absorption reduces power usage compared to traditional SCR/SNCR systems.

Compact & Modular Design: Easy installation, flexible for retrofit or new plant setups.

Corrosion-Resistant Materials: PP, FRP, or stainless steel construction for long-term durability.

Automated Control System: Real-time monitoring & adjustment for optimal performance.

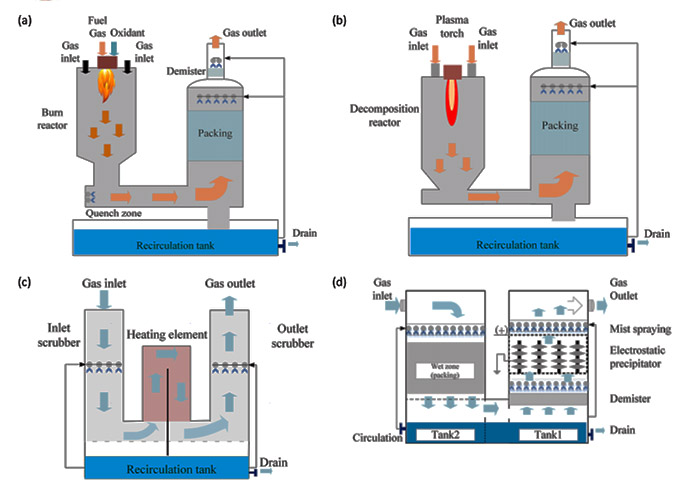

What is the principle of Multistage Jet Waste Gas Treatment Equipment High Concentration Nitrogen Oxide Removal?

The Multistage Jet Waste Gas Treatment Equipment operates in three key stages:

Gas Intake & Pre-Treatment – NOx-laden gas enters the system, where particulates are filtered.

Multi-Stage Chemical Absorption – Gas passes through jet reactors, where it reacts with absorbents (e.g., urea, ammonia, or alkaline solutions) to convert NOx into harmless N₂ & H₂O.

Purification & Emission – Treated gas undergoes final scrubbing before clean discharge.

Multistage Jet Waste Gas Treatment Equipment High Concentration Nitrogen Oxide parameters

| arameter | Specification |

|---|---|

| NOx Removal Rate | 90%~99% |

| Inlet Concentration | Up to 5000 mg/m³ |

| Operating Temperature | 60°C ~ 400°C |

| Pressure Drop | < 1000 Pa |

| Power Consumption | 20~50 kW (depending on capacity) |

| Material Options | PP, FRP, Stainless Steel 304/316 |

What are the applications of Multistage Jet Waste Gas Treatment Equipment High Concentration Nitrogen Oxide Removal?

Power Plants: Coal-fired, gas-fired, biomass energy

Chemical Industry: Nitric acid plants,fertilizer production

Metallurgy: Steel smelting, non-ferrous metal processing

Waste Incineration: Municipal & hazardous waste treatment

Cement & Glass Manufacturing: Kiln exhaust gas cleaning

Multistage Jet Waste Gas Treatment Equipment High Concentration Nitrogen Oxide Removal Customer Case

A coal power plant in China reduced NOx emissions from 4500 mg/m³ to < 100 mg/m³, achieving 98% removal efficiency.

A chemical factory in Germany cut operational costs by 30% compared to SCR systems while meeting EU emission standards.