Gremet Waste Gas Treatment Equipment Wet Scrubber System

A highly efficient wet exhaust gas treatment equipment designed to remove harmful particulate matter, acid gases (such as SO₂, HCl, NH₃) and odors from exhaust gas

Price: $700-$20,000

Air volume: 1,000 - 100,000 m³/h

Removal efficiency: ≥ 99% Pressure loss: 500 - 2,000 Pa Material options: PP, FRP, stainless steelWhat is Gremet Waste Gas Treatment Equipment Wet Scrubber System?

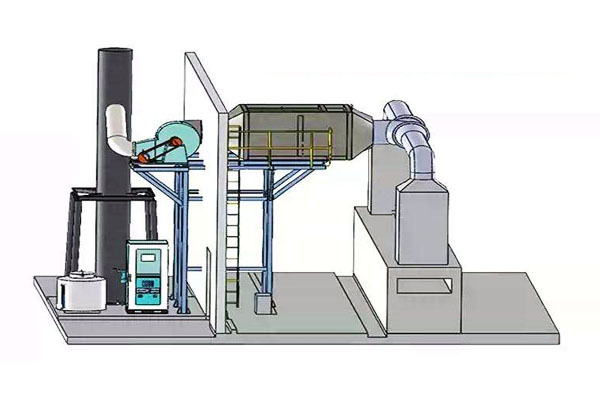

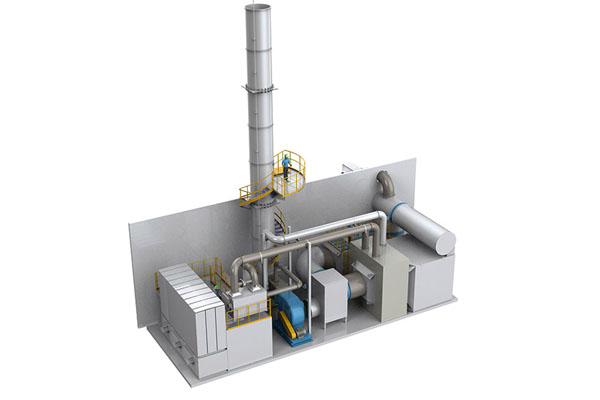

Gremet Waste Gas Treatment Equipment Wet Scrubber System is a highly efficient purification equipment designed for industrial waste gas treatment. The system uses advanced wet scrubbing technology to effectively remove acidic gases (such as HCl, SO₂), alkaline gases (such as NH₃), dust particles and volatile organic compounds (VOCs) in waste gas, ensuring that emissions meet international environmental standards (such as EPA, EU-IED).

Gremet Waste Gas Treatment Equipment Wet Scrubber System is widely used in chemical, pharmaceutical, electronic, metallurgical and food processing industries, providing customized waste gas treatment solutions to help companies achieve green production goals.

What are the advantages of Gremet Waste Gas Treatment Equipment Wet Scrubber System?

Gremet Waste Gas Treatment Equipment Wet Scrubber System is made of corrosion-resistant materials, can treat multiple pollutants at the same time, and has a purification efficiency of up to 99%. The intelligent control system can detect the treatment status at any time.

Ultra-high purification efficiency: Adopting optimized gas-liquid contact design, the pollutant removal rate is as high as 95%-99%.

Multi-pollutant treatment: Simultaneously treat particulate matter, acidic gas and odor, adapting to a variety of pollutants.

Low operating cost: Compared with traditional equipment, energy consumption is reduced by 30%, chemical agent consumption is reduced by 25%, and long-term enterprise cost savings.

Intelligent control system: Equipped with PLC automatic control, real-time monitoring of exhaust gas treatment effect and equipment operation status to ensure stable and standard emissions.

Corrosion-resistant material: The tower body is made of PP, FRP or 316L stainless steel, which is suitable for highly corrosive exhaust gas environment and prolongs equipment life.

How does Gremet Waste Gas Treatment Equipment Wet Scrubber System work?

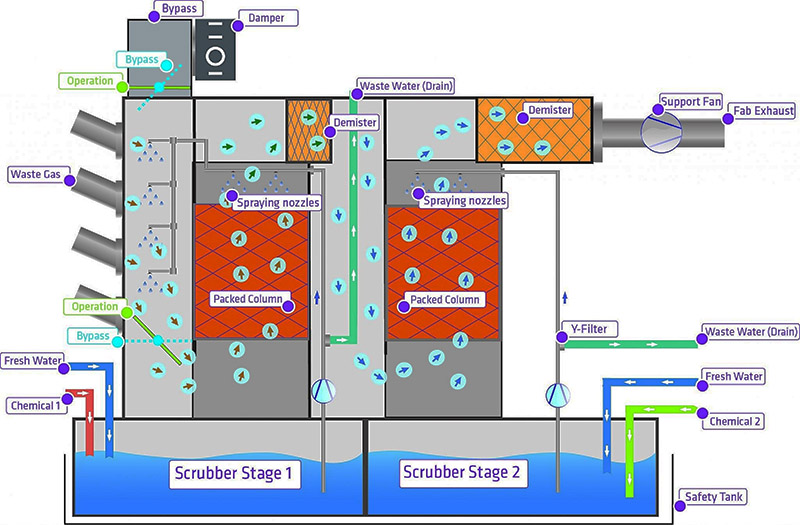

The exhaust gas enters the scrubber through the induced draft fan and fully contacts with the sprayed scrubbing liquid, and the pollutants are absorbed or neutralized. The packing layer increases the gas-liquid contact area and improves the purification efficiency. The treated clean gas is discharged after the residual water droplets are removed by the demister, and the scrubbing liquid is recycled or replaced regularly.

Gremet Waste Gas Treatment Equipment Wet Scrubber System parameters

| Parameters | Specifications |

| Air volume | 1,000-100,000 m³/h |

| Pressure loss | 500-1,500 Pa |

| Demisting efficiency | >99% |

| Material options | PP/FRP/316L stainless steel |

| Applicable temperature | -20°C to 120°C |

| pH control range | Acidic waste gas: 7-9; Alkaline waste gas: 4-6 |

| Power requirements | 380V/50Hz (customizable) |

| System noise | <75dB(A) |

What are the applications of Gremet Waste Gas Treatment Equipment Wet Scrubber System?

Gremet Waste Gas Treatment Equipment Wet Scrubber System is used in many industries to efficiently purify various harmful gases. In the chemical industry, it can treat acidic waste gases such as HCl, SO₂, and NOx; in the electronics industry, it is suitable for purifying the mixed waste gas of HF and HNO₃ generated in the semiconductor manufacturing process; in the metal processing process, it can effectively remove the smoke and gas released during welding and pickling; in the pharmaceutical industry, it can be used to remove organic waste gas and odor generated in fermentation and synthesis processes; and in the food processing field, it can treat the oil smoke and volatile organic compounds emitted during cooking and drying to ensure the production environment and air quality.

Gremet Waste Gas Treatment Equipment Wet Scrubber System Customer Cases

Chemical Plant HCl & SO₂ Waste Gas Treatment: A large chemical plant discharged HCl (300mg/m³) and SO₂ (500mg/m³) that exceeded the standard and needed to comply with EU emission standards (HCl<10mg/m³, SO₂<50mg/m³).

Solution: Gremet two-stage wet scrubber was used, with the first stage of clean water pre-washing to remove particulate matter, and the second stage of NaOH solution to neutralize acidic gases.

Effect: HCl removal rate of 98.5%, SO₂ removal rate of 97.3%, fully meeting the standard 3.

Electronics Factory HF Waste Gas Treatment: HF waste gas in semiconductor manufacturing is highly corrosive, and traditional equipment is easily damaged.

Solution: PP+PTFE anti-corrosion material scrubber, with automatic pH control and high-efficiency demisting device.

Result: HF removal rate of 99.2%, stable equipment operation, and extremely high customer satisfaction.