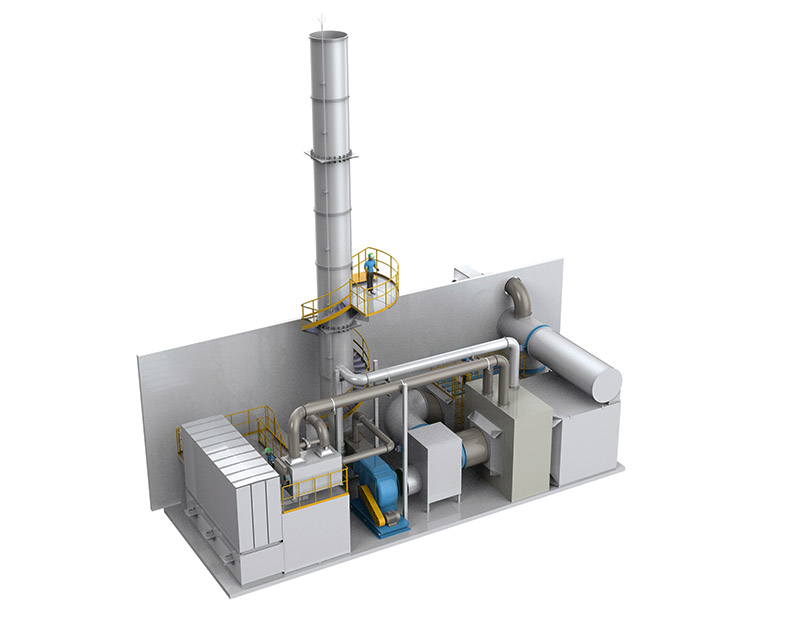

Copper Mine NOx Waste Gas Absorption Tower Wet Gas Scrubber

Air pollution control systems designed specifically for copper mining and smelting operations, effectively removing nitrogen oxides (NOx), sulfur dioxide (SO₂) and other harmful gases from industrial exhaust gases

Price: $600-$25,000

High Removal Efficiency (95%+ NOx Reduction)

Processing capacity: 100–150,000 m3/h

Waste gas temperature (inlet): 80~200°C

SO₂ removal rate: ≥95% (if present)

Tower material: FRP/PP/stainless steel 316L (corrosion resistant)

Tower diameter × height: Φ2.0~5.0m × 10~20m (depending on flow rate)

What is Copper Mine NOx Waste Gas Absorption Tower Wet Gas Scrubber?

Copper Mine NOx Waste Gas Absorption Tower Wet Gas Scrubber is a device designed for treating high-concentration nitrogen oxide (NOx) waste gas generated in metallurgical and precious metal refining processes. The device adopts a multi-stage injection and packed tower structure, combined with advanced gas-liquid separation and oxidation technology, which can efficiently convert NOx into harmless substances and meet environmental emission standards.

What types of Copper Mine NOx Waste Gas Absorption Tower Wet Gas Scrubber are there?

Copper Mine NOx Waste Gas Absorption Tower Wet Gas Scrubber can be divided into three types: multi-stage injection type, packed tower type and combined type. The required model can be selected according to the concentration of NOx waste gas treatment.

Multi-stage jet type wet scrubber: Suitable for high-concentration NOx waste gas treatment, with high purification efficiency.

Packed tower type wet scrubber: Suitable for low- and medium-concentration NOx waste gas treatment, compact structure, easy maintenance.

Combined wet scrubber: Combining jet and packed tower structures to meet various working conditions.

What are the advantages of Copper Mine NOx Waste Gas Absorption Tower Wet Gas Scrubber?

Copper Mine NOx Waste Gas Absorption Tower Wet Gas Scrubber is convenient and efficient in purifying NOx waste gas. It has compact structure, fully automatic control, simple operation, low energy consumption and no secondary pollution. The specific advantages are as follows:

High purification efficiency: Multi-stage injection and packing tower design, NOx removal rate can reach more than 98%.

Compact structure: Small footprint, suitable for industrial sites with limited space.

Easy operation: Automatic control system, easy to operate and maintain.

Energy saving and environmental protection: Use high-efficiency oxidant to reduce energy consumption and secondary pollution.

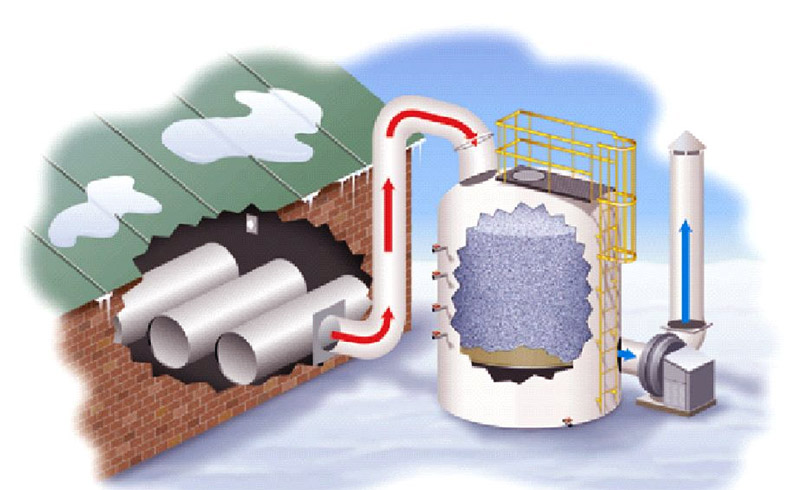

What is the principle of Copper Mine NOx Waste Gas Absorption Tower Wet Gas Scrubber?

Copper Mine NOx Waste Gas Absorption Tower Wet Gas Scrubber treats NOx exhaust gas through the steps of pretreatment, oxidation treatment, injection absorption and filler absorption:

Pretreatment: The waste gas enters the gas-liquid separator, condenses the acid mist and flows back to the reactor to reduce acid consumption and precious metal loss.

Oxidation treatment: The waste gas enters the buffer tank, and the oxidant is used to oxidize NO to NO₂ to improve the subsequent absorption efficiency.

Jet absorption: The waste gas passes through the jet tower and is fully mixed and reacted with the absorption liquid to further remove NOx.

Padding absorption: The unreacted NOx contacts the absorption liquid in the packing layer to complete the final purification.

Copper Mine NOx Waste Gas Absorption Tower Wet Gas Scrubber Specifications

| Parameter | Specification |

| NOx Removal Efficiency | 90-98% |

| SO₂ Removal Efficiency | 95-99% |

| Gas Flow Capacity | 5,000 – 500,000 Nm³/h |

| Operating pH Range | 6-9 (adjustable) |

| Pressure Drop | 500 – 2,500 Pa |

| Material Options | PP, FRP, 316L SS, C-276 Alloy |

| Automation Level | PLC-controlled with HMI interface |

What is the application of Copper Mine NOx Waste Gas Absorption Tower Wet Gas Scrubber?

Copper Mine NOx Waste Gas Absorption Tower Wet Gas Scrubber is mainly used to treat nitrogen oxides (NOx) and other acidic waste gases (such as SO₂, HF, HCl, etc.) generated in copper smelting, roasting, acid leaching and other processes. It purifies waste gas through chemical absorption and physical scrubbing to ensure that emissions meet environmental standards.

Copper ore smelting: Treatment of NOx waste gas generated during the smelting process.

Precious metal refining: Applicable to the refining process of precious metals such as gold, silver, platinum, palladium, and rhodium.

Chemical industry: Treatment of NOx waste gas generated during the production of nitric acid.

Laboratory: Waste gas treatment in laboratories of universities, research institutions, etc.

Copper Mine NOx Waste Gas Absorption Tower Wet Gas Scrubber Customer Case

A leading copper mine in Chile implemented our Wet Gas Scrubber to treat high-NOx exhaust (1,200 ppm) from their smelting furnace. After installation:

NOx emissions reduced by 96% (from 1,200 ppm to <50 ppm).

SO₂ levels cut by 98%, eliminating acid rain risks.

Annual compliance savings: $250,000+ in regulatory penalties.