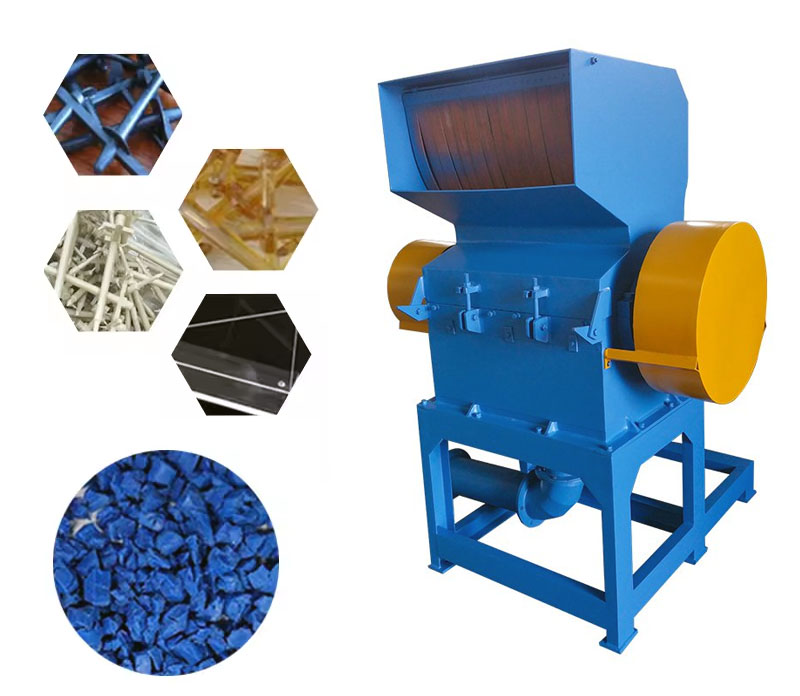

Rubber Coarse Crusher

It can crush large pieces of rubber waste into small chunks or coarse particles to prepare for subsequent processing. The price ranges from $1,000 to $14,000, depending on the model, production capacity, configuration, etc.

Feed size: ≤300mm

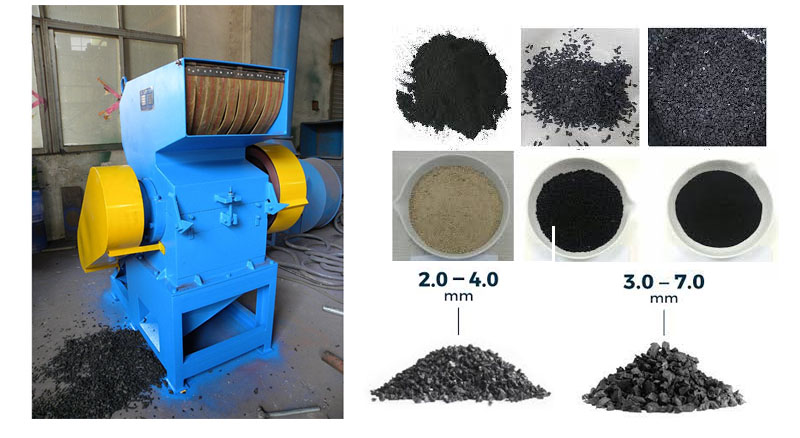

Crushing size: 0.5-20mm

Production capacity: 10-1200kg/h

Power: 1.5-55KW

What is Rubber Coarse Crusher?

Rubber Coarse Crusher is a device that uses shearing, tearing, and extrusion to crush waste rubber products such as tires, rubber seals, rubber hoses, and rubber shoe soles with a particle size ≤800mm into small pieces or coarse particles to prepare for subsequent processing. Its output particle size is between 10-50mm, and the crushing capacity is 1-5 tons per hour. Because waste rubber is a polymer material with a certain degree of elasticity, wear resistance, and aging resistance, high-toughness blades and a powerful drive system must be selected during crushing to overcome the elastic resistance of the rubber and complete the crushing process.

What types of Rubber Coarse Crusher are there?

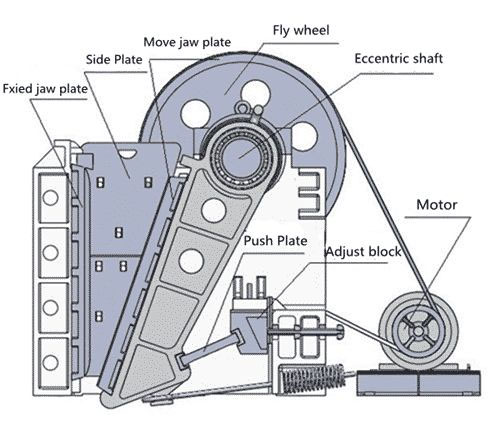

Based on their crushing principles, rubber coarse crushers can be classified into three types: shearing, impact, and extrusion. Different types of equipment are selected for rubber raw materials of different hardness and shapes.

Shearing Rubber Coarse Crusher: Consists of two or more sets of opposing rotating toothed rollers with helical or staggered blades. It shears and tears large pieces of rubber, and can also separate metal impurities from the rubber, such as steel wires from tires. It is commonly used for crushing rubber with high hardness and large volume, such as waste tires and scraps from large rubber products.

Impact Rubber Coarse Crusher: Contains a built-in high-speed rotating impact hammer or impeller, combined with a fixed impact plate. The high-speed impact force of the impact hammer repeatedly crushes the rubber block against the impact plate. It can be used for crushing medium-hardness rubber tubes, sealing rings, waste shoe soles, and other rubber materials.

Extrusion Rubber Coarse Crusher: Consists of one or more pairs of extrusion rollers with raised ridges on their surfaces. The spacing between the rollers can be adjusted according to requirements. It crushes and extrudes rubber blocks into sheets or small pieces by squeezing and pressing the rollers. It is mainly used for crushing soft rubber waste, rubber films, and other tough and difficult-to-shear rubber materials.

What are the advantages of Rubber Coarse Crusher?

The Rubber Coarse Crusher is constructed from high-strength steel, and its crushing chamber features wear-resistant alloy tooth plates and alloy blades, making it impact-resistant and corrosion-resistant. It can even crush highly elastic and tough rubber without causing frequent wear and tear on its parts. Its widened feed inlet design can crush rubber raw materials of various shapes, such as blocks, strips, and granules, ranging from 100mm to 800mm. The output particle size can be adjusted from 10 to 50mm according to requirements. Furthermore, the feed inlet size, material, motor function, and other parameters can be customized according to the characteristics of the material being crushed and the application scenario.

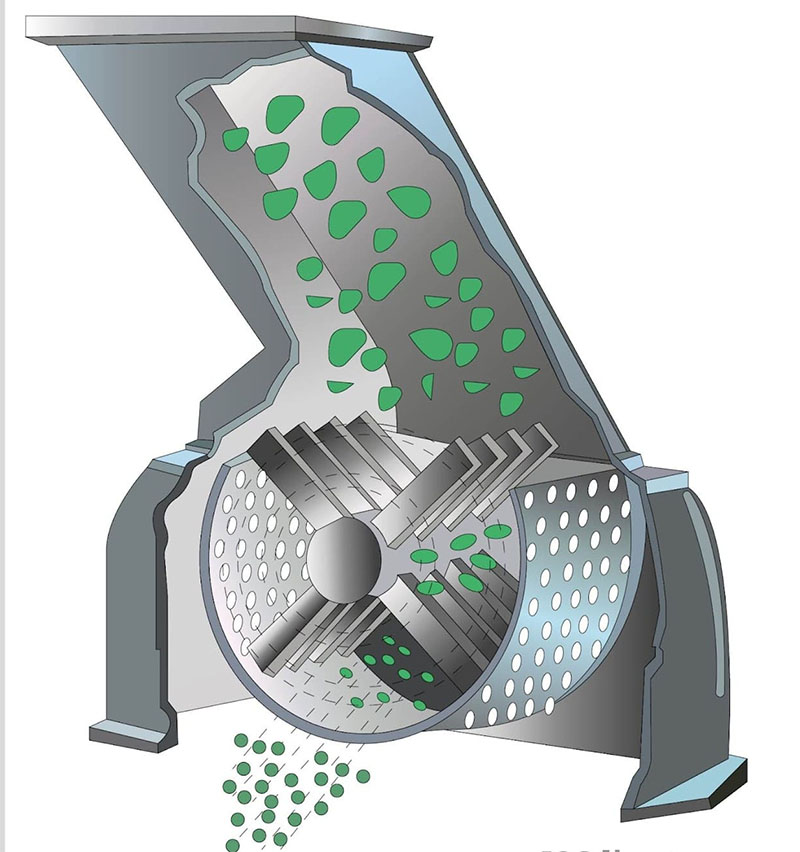

How does the Rubber Coarse Crusher work?

When the Rubber Coarse Crusher is in operation, the rubber enters the crushing chamber through the feed inlet. Inside the chamber, a motor-driven rotor rotates multiple alloy cutters at high speed. The sharp edges of the cutters generate shearing force on the rubber, while the impact force generated by the high-speed rotation of the rotor crushes and tears large pieces of rubber. The crushed rubber particles pass through a screen at the bottom of the chamber. Particles that meet the coarse crushing requirements are discharged through the screen holes, while those that do not meet the requirements remain in the chamber and are further processed by the cutters, ultimately completing the coarse crushing of the rubber.

Rubber Coarse Crusher Specifications

| Model | HHS-500 | HHS-600 | HHS-800 |

| Enter dimensions (mm): | 10-300 | 10-300 | 10-300 |

| Output size (mm): | 3-4 | 3-4 | 5-8 |

| Power (Kw): | 22 | 30 | 55 |

| Capacity (kg/hour): | 200-300 | 300-500 | 500-800 |

| Weight (kg): | 900 | 1200 | 1600 |

| Dimensions: (Length x Width x Height in millimeters) | 1580x1200x1600 | 1650x1360x1500 | 1750x1640x1900 |

What are the structural components of a Rubber Coarse Crusher?

The Rubber Coarse Crusher features a heavy-duty steel frame that provides stable support and resists impact loads during crushing. The crushing mechanism includes a rotating cutter roller and fixed cutters; the moving and fixed cutters on the roller work together in a shearing and crushing motion to break the rubber. It also includes a transmission system consisting of a motor, reducer, and coupling, providing stable power to the cutter roller. A feeding/discharging device is also included, with a guide structure at the feed inlet controlling the feeding speed and a conveyor at the discharge outlet. Finally, it includes safety devices such as a cutter roller guard and overload protection components.

What is the use of Rubber Coarse Crusher?

Rubber Coarse Crusher is used for primary crushing of various rubber products in rubber recycling and processing. It is mainly used for crushing waste tires (including radial tires and bias tires), rubber conveyor belts, rubber seals, rubber hoses, rubber sheets, rubber gaskets and other industrial and civilian rubber products. It can also process natural rubber blocks, nitrile rubber, neoprene rubber and other synthetic rubber blocks, as well as soft, semi-hard and hard rubber waste of different hardness. It can also be used for crushing and reprocessing scraps and defective products in rubber product manufacturing.

How to choose Rubber Coarse Crusher?

When selecting a Rubber Coarse Crusher, the first step is to determine the properties of the rubber. Different hardnesses of rubber used in tires, inner tubes, shoe soles, etc., will affect the selection of crushing blades. Secondly, production capacity should be considered. For small-scale production, the CSJ series (<200kg/h) should be selected, while for large-scale production, the TH/XFJ series should be selected. Finally, the output particle size should be selected, either coarse crushing (10-50mm) or fine crushing (0.2-2mm).

Rubber Coarse Crusher Manufacturer

MACHRISE Rubber Coarse Crusher manufactures a range of rubber shredders, including twin-shaft shredders, single-shaft shredders, shear crushers, impact crushers, and extrusion crushers. A full range of models and specifications are available, with direct sales from the manufacturer. These shredders are suitable for various materials such as waste tires, styrene-butadiene rubber, rubber shoe soles, and rubber product waste. Some models can achieve fine crushing down to 2mm. In terms of materials, the machine body is mostly welded from high-quality steel plates, the cutter shaft is made of high-strength heavy-duty special steel, and the blades commonly use alloy tool steels or cold work die steels such as Cr12MoV, SKD-11, and 9CrSi. High-hardness models can also use cemented carbide. The crushing blades can be selected from single-axis moving blades, dual-axis 3-jaw/8-jaw/12-jaw blades, symmetrical stepped claw blades, and hammer blades, etc. Customizable additional functions include PLC automatic control system, overload reverse protection, double-layer soundproof feeding hopper, crushing chamber cooling water device, automatic feeding mechanism, magnetic iron removal device and screens with different apertures can also be added. Some models can be customized as ATEX explosion-proof version or wear-resistant reinforced model.

Metal Coarse Crusher

Metal Coarse Crusher