Size of Test Sieve

Thursday July-17 2025 13:34:35

How Does Test Sieve Size Determine Screening Efficiency?

The size of a Test Sieve is a core factor determining the success of screening operations, as its sieve frame diameter and depth directly impact screening efficiency, processing capacity, and precision control. As a key tool for particle size analysis in laboratories and grading in industrial production, test sieve sizes range from 75mm (miniature) to 1000mm (super large), adapting to diverse needs from milligram-level samples to ton-scale materials. Whether for precise testing in university laboratories or large-scale screening in mining and chemical industries, selecting the right size can significantly enhance screening effectiveness.

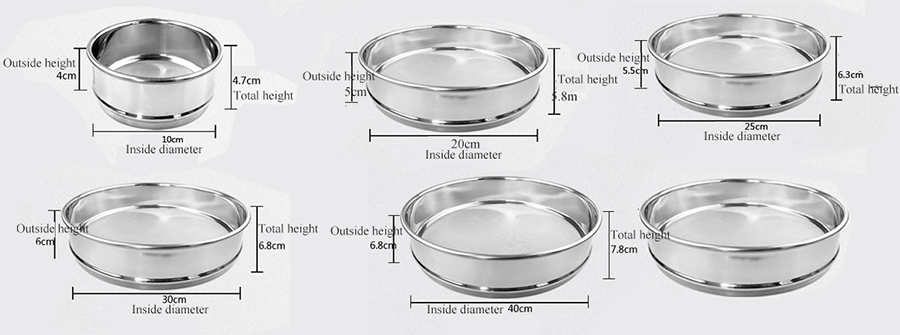

What Are the Core Parameters of Test Sieve Sizes?

Test sieve sizes are defined by two primary parameters: sieve frame diameter and sieve frame depth

Diameter: The outer diameter of the circular sieve frame, ranging from 75mm (miniature) to 1000mm (super large). It directly determines the single-batch screening capacity (e.g., a 200mm frame handles 50–200g, while a 600mm frame processes 5–10kg).

Depth:The vertical height from the sieve mesh to the frame edge, commonly available in 25mm (shallow type, suitable for fine powders), 50mm (standard type, general use), and 100mm (deep type, for large particles/high-capacity processing). This parameter affects the movement space and retention of materials on the sieve surface.

Specific test sieve size

The below table shows the detailed data of different models of laboratory test sieves use stainless steel 304 test sieves for your reference.

| Mesh shape | Diameter | Effective screen surface diameter | H | |

| Min | Max | |||

| round | 75mm | 75mm | 65mm | 25mm |

| 200mm | 200mm | 185mm | 25mm, 50mm | |

| 300mm | 300mm | 275mm | 75mm | |

| square | 300mm | 300mm | 75mm | |

If you have special requirements, please click on the contact us below to provide you with professional and customized services.

| Serial Number | Name | Unit | Date | |

| 1 | Standard sieve body | layer | 8 | |

| 2 | Screen diameter | mm | φ200φ100φ75 | |

| 3 | Screening size | mm | 0.038-3 | |

| 4 | Noise | dB | ≤50 | |

| 5 | Feeding amount (one time) | g | ≤200 | |

| 6 | Amplitude | mm | ≤5 | |

| 7 | Motor | voltage | V | |

| Rotating speed | r/min | 1420 | ||

| Power | KW | 0.125 | ||

| 8 | Dimensions | mm | 360×300×736 | |

| 9 | Machine quality | kg | 25 | |

How to Choose the Right Test Sieve Size Based on Requirements?

Processing capacity, precision, equipment compatibility, and industry standards are the core factors in selecting test sieve sizes.

Prioritizing Processing Capacity:

Micro Screening (<100g per batch): Opt for 75–100mm miniature sieve frames, ideal for laboratory-scale handling of milligram-level samples (e.g., nanomaterials, precious metal powders).

Medium-Low Volume Screening (100g–5kg per batch): Use 200–400mm standard sieve frames, suitable for industrial routine production. These match medium-sized vibrating screens and balance efficiency with precision (e.g., chemical powders, food granules).

Large-Scale Production (>5kg per batch): Require 500–600mm large-size sieve frames. Their deep design and reinforced frames support continuous ton-scale processing, fitting high-capacity equipment (e.g., ore rough screening, plastic pellet grading).

Prioritizing Precision:

Micron-Level Fine Screening (5–100μm): Recommend 200mm diameter with a 25mm shallow frame to minimize particle retention and enhance pass-through rate, critical for precision tasks like pharmaceutical particle testing or lithium battery powder analysis.

Millimeter-Level Coarse Screening (>1mm): Suit 300mm+ diameter with a 50mm deep frame, providing larger movement space to accelerate screening and reduce mesh blockage (e.g., ore particle separation, construction aggregate grading).

Ensuring Equipment Compatibility:

Non-Standard Automated Production Lines (e.g., custom linear vibrating screens): Offer customized sieve frames with precise dimension drawings, ensuring seamless flange interface matching (diameter tolerance ≤±0.5mm, flatness ≤0.1mm).

Meeting Industry Standards & Special Scenarios:

Export to EU/North America: Require 200mm ISO-standard sieve frames with CE/UL certifications for compliance with strict quality control regulations.

Food & Pharmaceutical Industry: Select 300mm sieve frames in 316L stainless steel to meet FDA/GMP cleanliness standards and prevent metal contamination.

High-Temperature/Corrosive Environments (e.g., refractory material screening, chemical slurries): Use 310S stainless steel (resistant to 1200℃ high temperature) or Teflon-coated frames (acid/alkali resistance), customized in diameter (e.g., 300mm high-temperature frames) for stable performance in harsh conditions.

Selecting the right test sieve size is more than parameter matching—it’s a balance of screening efficiency and cost-effectiveness. From laboratory-grade micron-level precision to industrial-scale millimeter-level grading, every scenario demands tailored dimensions. With our full-range size coverage, we provide both 75–600mm ready-to-ship standard frames and 50–1000mm customized non-circular solutions, ensuring tolerance control, material performance, and standards compliance.

Start efficiently—contact us for a free size-selection consultation and professional quote. Let every test sieve be your precise partner in material grading.