Application of Solid Liquid Separation Equipment

Monday July-14 2025 18:08:32

Why Have Solid-Liquid Separation Equipment Become Essential in Industrial Production?

In the global industrial system, from chemical slurry purification to food and beverage clarification, and from wastewater treatment to mineral resource recovery, the efficiency of solid-liquid separation directly affects product quality, resource utilization, and environmental compliance. Traditional manual separation or simple filtration equipment face issues such as high energy consumption, low precision, and poor adaptability. However, modern solid-liquid separation equipment, through the integration of mechanical engineering and fluid dynamics, achieves efficient separation of materials ranging from micron-sized particles to high-concentration slurries. This article will analyze how such equipment has become a standard solution in chemical, food, environmental protection, and other industries from the perspectives of applicable materials, working principles, industrial applications, and core advantages.

Which Complex Materials Require Professional Solid-Liquid Separation Equipment?

Solid-liquid separation equipment is designed for mixtures with different phases, viscosities, and particle sizes, covering over 90% of industrial separation scenarios.

High-concentration slurries: Materials with a solid content of ≥30% such as mine tailings and starch processing wastewater are suitable for high-frequency vibrating screens. Equipped with a 3000rpm high-speed vibration motor, they break up particle agglomeration through high-frequency micro-amplitude vibrations, achieving a processing capacity of 5-48 tons/hour to meet the needs for large throughput and high separation efficiency.

Ultra-fine particle suspensions: Materials with particle sizes ≤50μm such as nano-catalyst slurries and pharmaceutical intermediate solutions are separated by filter sieves paired with 400-mesh micron-grade filter cloth. By applying pressure through a single-layer screen, impurities are intercepted, achieving a 99.9% solid-liquid interception rate to ensure high material purity.

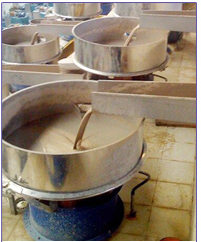

Thermosensitive/emulsifiable materials: Sensitive materials such as fruit juices and biological fermentation broths are processed using vibro sifters. Three-dimensional vibrations (amplitude 0.5-3mm) enable gentle separation, avoiding damage to component activity and ensuring product quality in the food and pharmaceutical industries.

How Do Solid-Liquid Separation Equipment Achieve Efficient Phase Separation?

Vibro Sifter: Generates composite vibrations (vertical, horizontal, and tangential) with an amplitude of 0.5-3mm via a three-dimensional vibration motor, allowing fine particles to pass through the screen with liquids while coarse particles are discharged along the screen edges. With a screen precision of 5μm-400 mesh and a processing capacity of 100-3300kg/h, it is suitable for separating medium-fine particles (e.g., removing soybean residue from soymilk or seeds from fruit juice), featuring excellent anti-agglomeration performance and suitability for small to medium batch materials.

Filter Sieve: Relies on mechanical pressure applied through a single-layer screen to force liquids through screen holes (aperture 5μm-30mm) while intercepting solid impurities. With a processing capacity of 400-1200kg/h, it has a compact structure and easy operation, making it ideal for materials with good fluidity and few impurities (e.g., filtering latex paint or purifying liquid medicines). It is the preferred single-layer screening equipment for small and medium-sized enterprises.

High-Frequency Vibrating Screen: Equipped with a 3000rpm high-speed motor, it breaks up agglomeration of high-viscosity particles through high-frequency micro-amplitude vibrations. With a screen aperture <30mm and a processing capacity of 5-48 tons/hour, it is specifically designed for high-viscosity slurries such as ceramic glazes and mud, ensuring anti-clogging efficiency and stable operation under large throughput.

| Type | Vibro Sifter | Filter Sieve | High Frequency Vibrating Screen |

| Features | It adopts the edge design to prevent the splashing of liquid materials, and it is also convenient to observe the operation of materials on the screen surface at any time. | It is suitable for single-layer screening and filtering of manufacturers in various industries. It can handle materials with small production volume or less impurities and good fluidity. It is a screening and filtering equipment for small and medium-sized enterprises. | It adopts a 2-stage high-frequency vibration motor with a speed of 3000 rpm, which is suitable for viscous slurry, such as ceramic glaze, mud, paint, etc. |

| Mesh size | 5 microns | 400 mesh | 30mm |

| Capacity | 100-3300kg/h | 400-1200kg/h | 5-48 tons/hour |

In Which Industries Do Solid-Liquid Separation Equipment Play a Key Role?

Their versatility makes them indispensable across the entire industrial chain from basic industries to high-end manufacturing.

Food and Beverage Industry: In soymilk production, 120-mesh screens filter out soybean residue to improve taste purity with a processing capacity of 1200L/h; in fruit juice processing, 80-mesh screens separate pulp from liquids to ensure clarity, achieving a production capacity of 6-10m³/hour.

Environmental Protection and Wastewater Treatment: For domestic sewage, 5-20 mesh coarse screens intercept hair, plastic debris, and other impurities to reduce subsequent treatment loads; in industrial wastewater treatment, 30mm aperture screens filter ceramic glazes to remove coarse particles, preventing pipe blockages and enabling water recycling.

Chemical and Pharmaceutical Industries: In latex paint production, 325-mesh screens filter out impurities to ensure coating uniformity with a processing capacity of 1200L/h; in pharmaceutical extraction, 600-mesh ultra-fine screens purify Chinese medicine liquids to meet injection-grade purity standards.

Mining and Building Materials: In tailings treatment, high-frequency vibrating screens with 12-mesh screens separate ore particles to recover valuable metals and reduce tailings discharge; in ceramic slurry production, filtering out impurities in glazes avoids bubbles during firing, improving product qualification rates.

What Breakthroughs Do Modern Solid-Liquid Separation Equipment Offer Compared to Traditional Methods?

Five core advantages drive the industry from "functional" to "efficient and precise":

Material Durability: The main body (material-contacting parts) is made of SUS304 stainless steel, offering 3x improved corrosion resistance, suitability for acidic/alkaline environments (e.g., calcium hydroxide slurry filtration), and an extended service life of 8-10 years.

Anti-Splashing and Automation: Heightened screen frames (5-10cm raised edges) prevent slurry splashing, paired with 360° automatic spray cleaning systems for 100% screen cleaning, reducing manual maintenance costs by 40%.

High Efficiency: Large-diameter discharge ports (50-100mm) with streamlined channels achieve a maximum processing capacity of 3300kg/h, avoiding material accumulation and adapting to continuous production lines.

Precise Classification: Covering a full range of screen sizes (5μm-30mm), they support applications from nano-grade purification (e.g., cosmetic emulsions) to coarse particle separation (e.g., coal washing wastewater), with particle size control deviation ≤±2%.

Solid-liquid separation equipment are not only "purifiers" in industrial production but also "accelerators" for efficient resource utilization. From deep dehydration of high-viscosity slurries to precise separation of nano-sized suspensions, their technological progress continues to break through traditional process bottlenecks, providing multiple values such as quality assurance, cost optimization, and green transformation for chemical, food, environmental protection, and other industries. As global manufacturing moves toward refinement and green development, choosing suitable solid-liquid separation solutions has become a necessity to enhance production line competitiveness and meet stringent regulations.