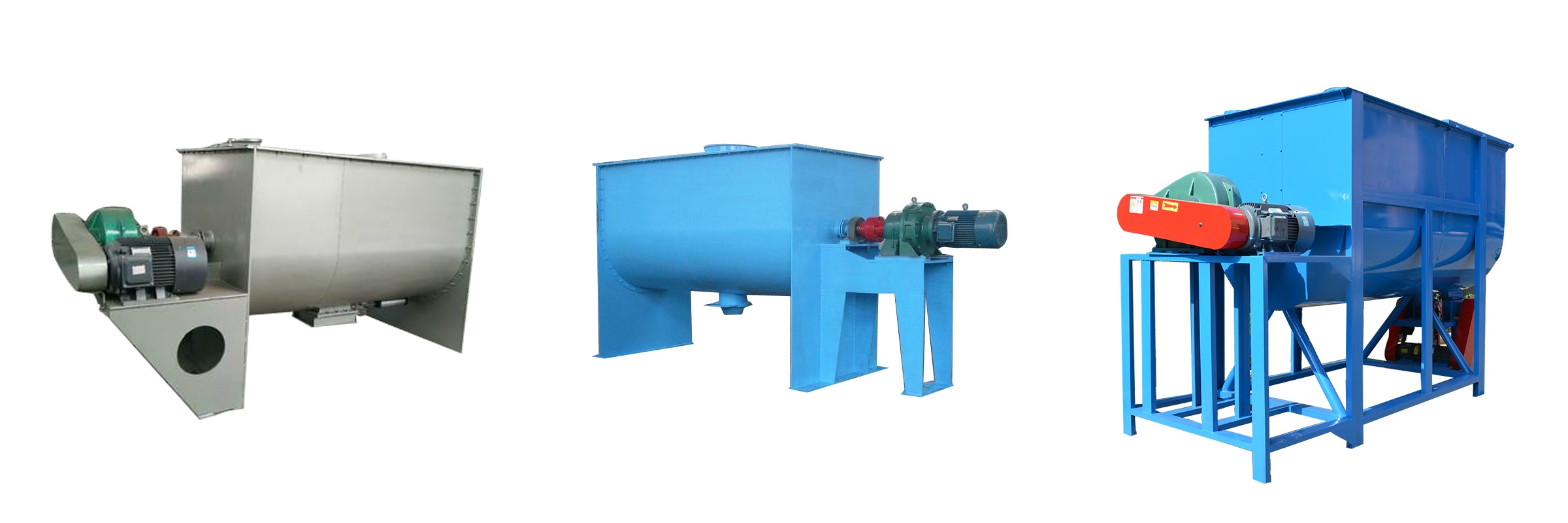

What is a Horizontal Stainless Steel Ribbon Mixer

Horizontal stainless steel ribbon mixer is an efficient mixing equipment widely used in many industries. It is based on a U-shaped stainless steel cylinder, with double or multi-layer spiral blades installed on the internal transmission main shaft, and the main shaft is driven to rotate by the motor through the reducer.

Fast mixing speed: The efficient mixing mechanism greatly shortens the mixing time

Extreme uniformity: The material can achieve three-dimensional compound movement in the cylinder, and achieve a highly uniform mixing effect in a very short time

One machine for multiple uses: whether it is dry powder, viscous slurry, fragile particles, or materials that need to add a small amount of liquid

Application scenarios: Food, chemical, pharmaceutical, feed and other fields, to meet the mixing needs of powder, granular and paste materials

Product description

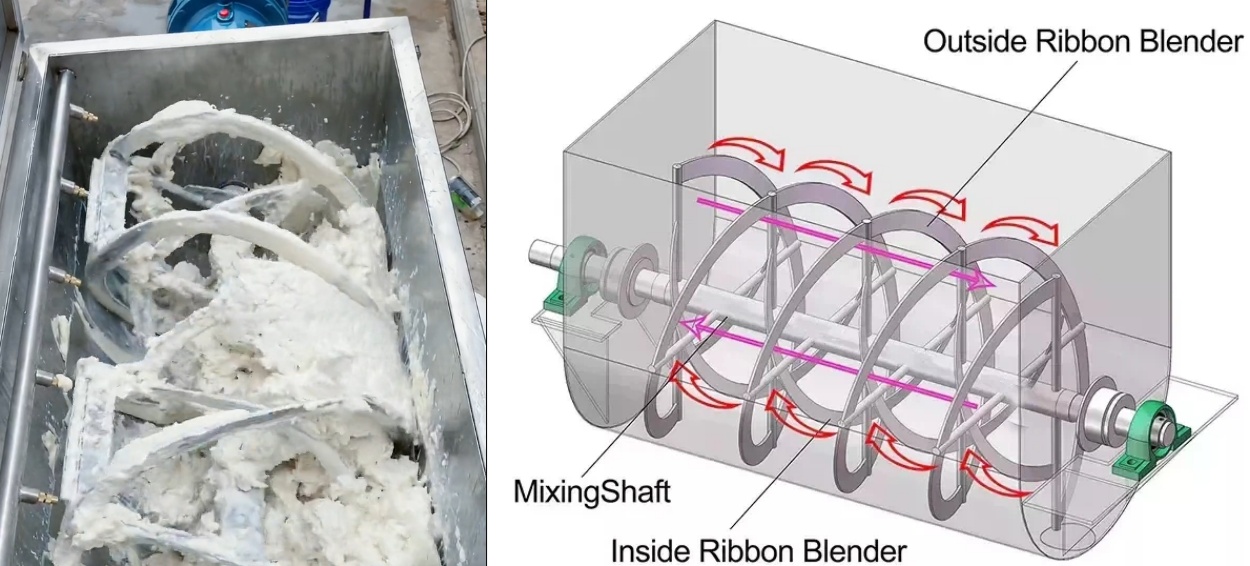

Horizontal stainless steel ribbon mixer is an efficient and hygienic mixing equipment, mainly used for uniform mixing of powders, particles, slurries and other materials. Its core is a horizontal U-shaped cylinder, which is equipped with special inner and outer double or multi-layer spiral ribbon agitators. When the agitator rotates, the outer spiral ribbon pushes the material from both ends to the center, and the inner spiral ribbon pushes the material from the center to both ends, forming a unique convection cycle and multi-dimensional tumbling, ensuring that the material achieves a highly uniform mixing effect in a short time.

Differences between horizontal stainless steel ribbon mixer and other types of mixers

|

Comparison dimension |

ribbon mixer |

other types of mixers (such as paddle type, vertical type) |

|

Mixing principle |

double-layer ribbon forms a "pushing inside and pulling outside" convection movement, and the material circulates and turns over in a large range in the barrel, with no dead angle mixing |

paddle type relies on the rotation of blades to push the material to move locally, and vertical type relies on gravity to mix from top to bottom, which is prone to mixing blind spots |

|

Uniformity |

mixing uniformity CV value ≤ 5%, can handle materials with a ratio difference of 1:10000 (such as trace additives and bulk raw materials) |

uniformity CV value is usually >10%, and the mixing effect of materials with large ratio differences or large specific gravity differences is poor |

|

Mixing time |

each batch of materials takes 1-10 minutes to complete mixing, and the efficiency is 6-10 times higher than that of ordinary mixers |

paddle type takes 20-30 minutes, and vertical type may take longer, which is suitable for simple mixing with low requirements |

Working principle of horizontal stainless steel ribbon mixer

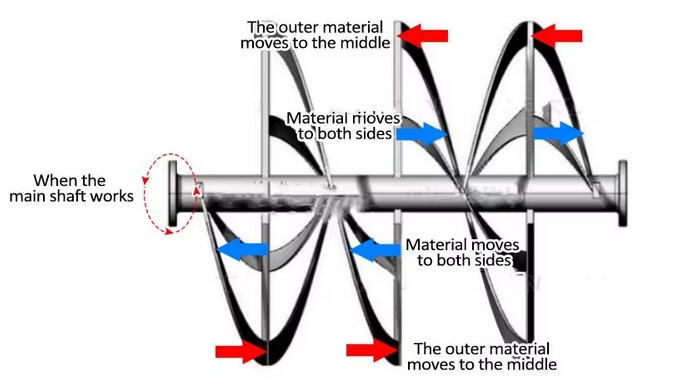

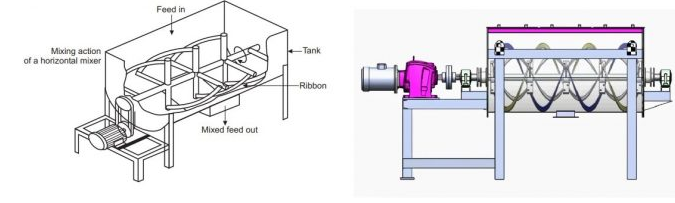

Its main body is a U-shaped stainless steel barrel with a main shaft in the barrel, and two layers of spiral blades are welded on the main shaft (like a spring twisted together). After the motor starts to rotate with the main shaft, the two layers of spirals start to work. When the inner layer of spiral blades rotates, it will push the material near the center of the barrel to both sides, while the outer layer of spiral blades will do the opposite, pushing the material near the barrel wall to the center. In this way, the material in the center is pushed to the side, and the material on the side is pushed back to the center. The whole process is like the material flipping back and forth in the barrel, constantly convection, interlacing, and diffusion. With the continuous rotation of the spiral blades, the material will be stirred more and more evenly, even materials with large weight differences (such as gravel and sand) can be mixed very evenly.

Structural composition of horizontal stainless steel ribbon mixer

Barrel: It is the core space where the mixing process occurs. It has a horizontal cylindrical structure, which can not only stably carry the material, but also facilitate the flow and flipping of the material in the horizontal direction.

Double-layer ribbon impeller: The engine for material mixing is composed of two layers of inner and outer ribbons installed on the central main shaft to form a "two-way mixing flow". The outer spiral ribbon pushes the material from both ends to the center, and the inner spiral ribbon pushes the material from the center to both ends; the materials in the two flow directions constantly intersect, dislocate, and shear in the middle, thereby achieving a multi-level mixing effect.

Main shaft and bearing: connect the motor and the spiral ribbon agitator to withstand the resistance torque of the material during the entire mixing process.

Characteristics of horizontal stainless steel spiral ribbon mixer

Excellent mixing effect: It adopts an inner and outer double-layer spiral ribbon structure, the inner spiral conveys the material to the outside, and the outer spiral gathers the material to the inside. This design allows the material to form a strong convection movement in the barrel, achieving a large range of circulation and flipping, thereby achieving a high degree of mixing uniformity in a short time. Whether it is the mixing of powder and powder, powder and slurry, or materials with large differences in mixing ratios, it can cope well, and can mix materials with a ratio of 1:10000 evenly, and the mixing uniformity CV value can be ≤5%, which can meet many scenarios with high requirements for mixing accuracy.

Wide range of applications: From the perspective of material types, it can handle a variety of materials, such as viscous putty paste, real stone paint, and powder materials such as dry powder and feed, and even solid-slurry mixing containing liquid. In terms of industry applications, it can be used in many industries such as food, medicine, chemical industry, feed, ceramics, refractory materials, etc., such as the mixing of zongzi fillings and milk powder additives in the food industry, and the mixing of pharmaceutical raw materials in the pharmaceutical industry.

Convenient and clean discharging: The bottom usually adopts a pneumatic large-opening door structure. For powder materials, this discharging method has a very fast unloading speed and can achieve no residue, which greatly improves production efficiency and avoids problems such as cross-contamination caused by material residues. For high-fineness materials or semi-fluid materials, manual butterfly valves or pneumatic butterfly valves can be used, which can also meet the discharging needs well.

Technical parameters of horizontal stainless steel ribbon mixer

|

Model |

Effective volume (L) |

Motor power (kW) |

Equipment size (mm) |

Reference weight (kg) |

|

WLD-100 |

100 |

1.5 |

1200×500×900 |

250 |

|

WLD-500 |

500 |

5.5 |

2000×800×1400 |

650 |

|

WLD-1000 |

1000 |

7.5 |

2500×1000×1600 |

1000 |

|

WLD-2000 |

2000 |

11 |

3200×1200×1800 |

1500 |

|

WLD-3000 |

3000 |

15 |

3800×1500×2000 |

2200 |

Application scenarios of horizontal stainless steel ribbon mixer

Horizontal stainless steel ribbon mixer is widely used in powder, granular and material mixing processes with a small amount of liquid in many industries due to its simple structure, uniform mixing and strong adaptability. In the seasoning production workshop, dozens of fine powdered raw materials (such as salt, monosodium glutamate, chili powder, spices, etc.) need to be mixed quickly in proportion for each batch. Customers require consistent taste without color difference or agglomeration. The ribbon design can realize material flipping and axial circulation, so that a variety of spices can be mixed evenly within a few minutes, without sticking to the wall and dead corners, ensuring the uniform quality of each batch of seasoning. Dry mortar manufacturers have to process hundreds of tons of cement, quartz sand, rubber powder and other mixed materials every day, with high requirements for efficiency and uniformity. Customers also need to adjust the amount of water or additives according to the formula. The ribbon of the horizontal stainless steel ribbon mixer efficiently pushes the heavy powder to flip and mix, with fast discharge and less residue; it also supports the installation of a spray system to meet dry and wet mixing.

Case display of horizontal stainless steel ribbon mixer

Mixing of milk powder and solid beverages: A large dairy company uses a horizontal stainless steel ribbon mixer to mix milk powder and solid beverages of different formulas (such as coffee companion, cereal, etc.). The equipment is made of food-grade stainless steel to ensure product hygiene and safety. The mixer can quickly and evenly mix powder raw materials of different densities to avoid agglomeration and ensure the taste and solubility of the final product.

Mixing of Chinese medicine formula granules: A pharmaceutical factory uses a horizontal stainless steel ribbon mixer to mix a variety of Chinese medicine extract powders in a specific proportion to make Chinese medicine formula granules. The interior of the mixer is highly polished, without dead corners, easy to clean and disinfect, meeting GMP (Good Manufacturing Practice) requirements and avoiding cross contamination.

Dry mortar production: Building materials companies use large horizontal stainless steel ribbon mixers to produce dry mortar, putty powder, tile adhesive and other products. The mixer can quickly mix cement, sand, additives and other materials of different particle sizes to improve product quality and construction performance.