Water Circulation U-shaped Screw Conveyor

The price of the Water Circulation U-shaped Screw Conveyor varies depending on the material, size, processing capacity. Its price ranges from $400 to $7,000.

Screw diameter: 100-630mm/customizable

Pitch: 100-580mm/customizable

Speed: 16-140 rpm/customizable

Conveyor capacity: 5-170m3/h/customizable

Material: Carbon steel/stainless steel 304/316L

Power: 22kw

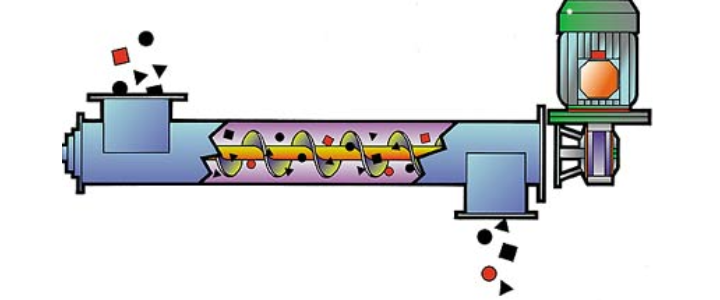

What is Water Circulation U-shaped Screw Conveyor?

Water Circulation U-shaped Screw Conveyor is a common material conveying equipment, suitable for conveying various types of bulk materials, including powder, granular, small blocks, and semi-fluid materials containing a certain amount of moisture or viscosity. Depending on the diameter and speed of the screw, the material handling capacity of the equipment varies, and it can usually achieve a material conveying volume of several cubic meters to tens of cubic meters per hour. In practical applications, the effective conveying distance of a single device is usually within tens of meters, depending on the material characteristics and site layout requirements.

What are the advantages of Water Circulation U-shaped Screw Conveyor?

As a specially designed material conveying equipment, the core advantage of Water Circulation U-shaped Screw Conveyor lies in the cooling system, which is used to solve the problem of high-temperature materials in the conveying process. It not only has the basic functions of a traditional U-shaped screw conveyor, but also gives the equipment excellent temperature control capabilities through the design of a circulating water jacket or coil, thus bringing a series of significant application advantages.

Temperature control and cooling effect: The outstanding advantage of Water Circulation U-shaped Screw Conveyor is its active cooling function. A jacket or coil is set in the center of the conveyor casing and the spiral shaft, and the heat generated by the material can be taken away by the continuous flow of circulating water. This feature makes it an ideal choice for handling ash from thermal power plants, clinker from cement plants, sintered ore from the mining industry, and high-temperature powdered and granular materials generated in other chemical processes.

Protect equipment and extend service life: High-temperature materials directly entering ordinary conveyors will cause the machine body (such as the shell, spiral blades, and bearings) to deform, accelerate wear, and even be damaged due to overheating. The water circulation system can maintain the temperature of the equipment within a safe range, effectively avoiding thermal damage, thereby significantly extending the service life of the entire machine and reducing maintenance costs.

Ensure material performance and safety: Many materials are unstable at high temperatures. If they are not cooled in time, they may agglomerate, deteriorate, or react chemically, affecting the quality of the final product. The conveyor can complete the cooling process of the material while conveying and stabilize the material performance. At the same time, cooling also helps prevent the risk of combustion and explosion of certain high-temperature dust materials during transportation.

In addition to the unique cooling function, Water Circulation U-shaped Screw Conveyor also retains the inherent advantages of standard U-shaped screw conveyors:

Simple structure, easy maintenance: The overall design is mature and reliable, the structure is relatively simple, and it is easy to install, operate and maintain.

Good sealing: The upper part of the U-shaped groove can be sealed with a cover, and the entire conveying process is carried out in a closed space, which can effectively prevent material leakage and dust flying.

Flexible layout, multi-point feeding and discharging: According to the process requirements, the feed and discharge ports can be set at any position of the conveying line to achieve single-point or multi-point feeding and discharging, and the layout is flexible and convenient.

Parameters of Water Circulation U-shaped Screw Conveyor

| Specification | Main technical performance | Drive device | Drive device | Weight(kg) | |||

| Diameter | Length(m) | Yield( t/h) | Rotating speed(min) | Reducer | Electric motor | ||

| Model | Speed ratio | Power(kw) | |||||

| U 200 | -10 | 9 | 60 | ZQ250 | 23.34 | 1.1 | 726 |

| U 200 | -20 | 9 | 60 | ZQ250 | 23.34 | 1.5 | 1258 |

| U 250 | -10 | 15.6 | 60 | ZQ250 | 23.34 | 2.2 | 960 |

| U 250 | -20 | 15.6 | 60 | ZQ250 | 23.34 | 3 | 1750 |

| U 300 | -10 | 21.2 | 60 | ZQ350 | 23.34 | 3 | 1373 |

| U 300 | -20 | 21.2 | 60 | ZQ350 | 23.34 | 4 | 2346 |

| U 400 | -10 | 51 | 60 | ZQ400 | 23.34 | 5.5 | 1911 |

| U 400 | -20 | 51 | 60 | ZQ500 | 23.34 | 11 | 2049 |

| U 500 | -10 | 87.5 | 60 | ZQ400 | 23.34 | 7.5 | 2381 |

| U 500 | -20 | 87.5 | 60 | ZQ650 | 23.34 | 18.5 | 5389 |

| U 600 | -10 | 134.2 | 45 | ZQ750 | 23.34 | 22 | 3880 |

| U 600 | -10 | 134.2 | 45 | ZQ850 | 23.34 | 55 | 7090 |

What is the principle of Water Circulation U-shaped Screw Conveyor?

The working principle of Water Circulation U-shaped Screw Conveyor can be broken down into two core parts: the "conveying" principle of materials and the "cooling" principle of heat. These two principles are carried out simultaneously through sophisticated structural design, and finally realize the "conveying and cooling" of high-temperature materials.

Conveying principle: mechanical thrust of the spiral

This part is the same as the standard U-shaped screw conveyor. Its core is to use the rotating spiral blades to push the material forward.

Structure: It is mainly composed of a U-shaped trough body, a spiral shaft with spiral blades, an inlet and outlet, and a drive device (motor, reducer).

Process: The drive device starts and drives the spiral shaft to rotate in the U-shaped trough. The material is added from the feed port and falls into the U-shaped trough. The rotating spiral blade is like a "rotating inclined plane", which will generate a thrust along the spiral axis on the material. Due to the gravity of the material itself and the friction between the material and the groove wall, the material will not rotate with the spiral blades, but will slide forward along the axial direction of the U-shaped groove under the push of the blades. The material is continuously pushed from the feed end to the discharge end, thus completing the entire conveying process. Simply put, the essence of conveying is to rely on the rotation of the spiral body to "twist" the material forward.

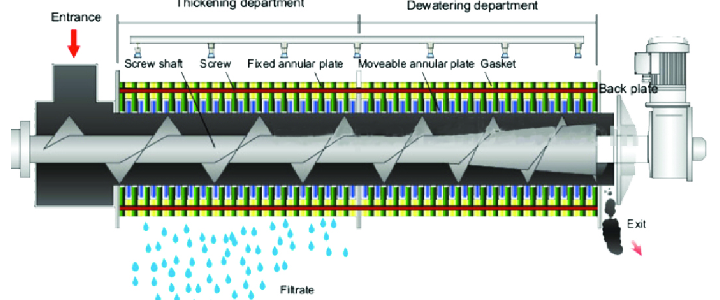

Cooling principle: heat exchange of water circulation

This is the key difference between Water Circulation U-shaped Screw Conveyor and ordinary conveyors. Its core is to use flowing cooling water to exchange heat indirectly with high-temperature materials.

Structure (cooling system): A closed water jacket will be designed outside the U-shaped groove of the main body. This jacket is like putting a "double coat" on the U-shaped groove, forming a hollow channel between the inner and outer walls, which is specially used for water flow. There are special cooling water inlets and outlets on the jacket.

Process: Inject cooling water, and the cooling water is pumped in from the inlet of the jacket through a water pump. The cooling water fills the entire jacket and continues to flow through it, surrounding the U-shaped trough containing high-temperature materials. The high-temperature materials inside the U-shaped trough transfer heat to the inner wall of the U-shaped trough through heat conduction. The inner wall of the U-shaped trough then transfers the heat to the outer wall. On the outer wall of the U-shaped trough, the heat is absorbed and taken away by the cooling water with a lower temperature flowing through the jacket. This is a typical indirect heat exchange process. The cooling water, which has absorbed a large amount of heat, increases its own temperature and becomes "hot water", and then flows out from the outlet of the jacket. The discharged hot water is usually sent to a cooling tower or a chiller for cooling, and the cooled water is pumped into the inlet of the conveyor jacket again, forming a continuous closed cooling cycle.

What are the applications of Water Circulation U-shaped Screw Conveyor?

Water Circulation U-shaped Screw Conveyor, commonly known as U-shaped screw conveyor, is a widely used equipment for conveying various bulk materials. Here are some of the main uses of U-type screw conveyors and their applications related to "water circulation" or material handling containing moisture:

Bulk material conveying: It can convey various bulk, powdered, granular and small block materials such as grains, feed, coal, cement, ore, chemicals, building materials, ash, etc. horizontally, obliquely or vertically.

Material mixing and stirring: Through specially designed spiral blades, U-type screw conveyors can mix, stir or crush materials during conveying, which is suitable for scenes requiring homogenization.

Feeding and metering: By controlling the speed of the screw, the U-type screw conveyor can accurately control the conveying amount of materials and realize the functions of feeding and metering.

Conveying with limited space: Its compact structure enables it to work in places with limited space.

Sludge conveying: During the sewage treatment process, a large amount of sludge is generated. U-type screw conveyors (especially shaftless screw conveyors, which usually also use U-shaped troughs) are very suitable for conveying dehydrated sludge, mud cakes, etc. with high viscosity and high moisture content, because they are not easy to entangle or clog, and have self-cleaning functions.

Grid slag transportation: Before the sewage enters the treatment system, it is necessary to intercept larger solid debris (grid slag) through the grid. The U-shaped screw conveyor can effectively transport these solid debris from the grid.

Sand and water mixture transportation: The sand and water mixture separated in the grit chamber can also be transported by a screw conveyor.

Industrial wastewater treatment: Similar to sewage treatment plants, various wastewaters and slurries containing solid particles generated in industrial production are also often treated and transported using U-shaped screw conveyors.

Water Circulation U-shaped Screw Conveyor is very useful in scenarios where material temperature needs to be controlled in industries such as chemical and food processing. For example, handling hot furnace ash or particles that need to be cooled.

Manufacturer of Water Circulation U-shaped Screw Conveyor

Water Circulation U-shaped Screw Conveyor is mainly used to convey materials containing water, semi-fluid or high viscosity. It is commonly used in sewage treatment, sludge disposal and application scenarios where materials need to be cooled or heated. When selecting a Water Circulation U-shaped Screw Conveyor, you need to focus on the characteristics of the material, the conveying volume, the conveying distance and angle, and the working environment. The material characteristics include its viscosity, humidity, abrasiveness, corrosiveness and temperature, which directly affect the selection and surface treatment of the spiral blades and trough materials (such as carbon steel, stainless steel 304/316L, etc.). For example, for highly abrasive materials, it is necessary to consider thickening the wear-resistant layer or using special alloys; for corrosive media, stainless steel or anti-corrosion coatings are necessary. The conveying volume and distance determine the spiral diameter, speed and drive power. In addition, for materials containing a large amount of fibers or easy to entangle, the shaftless screw conveyor can effectively avoid blockage due to its center shaftless design. Manufacturers can usually provide in-depth customized services to meet specific working conditions. First of all, the design of the spiral blade is the key, including continuous, segmented, variable pitch, paddle, etc., which are used to achieve different conveying, stirring or mixing effects. For scenes that require cooling or heating, manufacturers can provide jacketed U-shaped troughs. By setting a layer on the outer wall of the trough and passing cooling water or heat medium, the temperature of the material during the conveying process can be controlled. Secondly, the customization of the sealing method is also very important. According to the requirements of different material characteristics, a variety of options such as packing seals, mechanical seals or gas seals can be provided to prevent material leakage or external impurities from entering. In addition, the selection of the drive device, the design of the inlet and outlet (such as multi-point inlet and outlet), and the structural adjustment of the legs and brackets are all manifestations of the manufacturer's customization capabilities. Manufacturers can provide an overall solution from preliminary design, material selection to final installation and commissioning based on the user's specific process flow, rather than just providing standardized products.

The performance of the Water Circulation U-shaped Screw Conveyor is limited by the physical properties of the material, environmental conditions, and the degree of matching of the operating parameters. When selecting and configuring, it is necessary to analyze the viscosity, humidity, abrasiveness, etc. of the conveyed materials, and consider the adaptability of the equipment in a specific environment. The products provided by manufacturers usually have certain standardized specifications, and can also be adjusted in terms of structural dimensions, material selection, spiral blade form, and sealing method according to the specific needs of users. These adjustments are intended to enable the equipment to adapt to different material handling requirements and on-site installation conditions, so as to meet specific material conveying functions.