Fully automatic unloading packaging machine price

Saturday January-31 2026 16:12:21

Currently, Fully automatic unloading packaging machine price on the market generally ranges from US$5,000 to US$20,000, depending on the configuration, degree of automation, and customer customization requirements. Fully automatic unloading and packaging machines are primarily used in industrial production processes for unloading and packaging various granular, powdered, and small-block materials, such as plastic pellets, chemical raw materials, grain, cement, and mineral powder. This equipment supports automatic unloading from large silos, ton bags, bulk bags, and other containers, achieving high-speed, precise quantitative packaging. A single machine can pack 15-40 tons per hour, depending on the material type and packaging specifications. This equipment is particularly suitable for continuous production lines, significantly improving production efficiency and reducing manual operations.

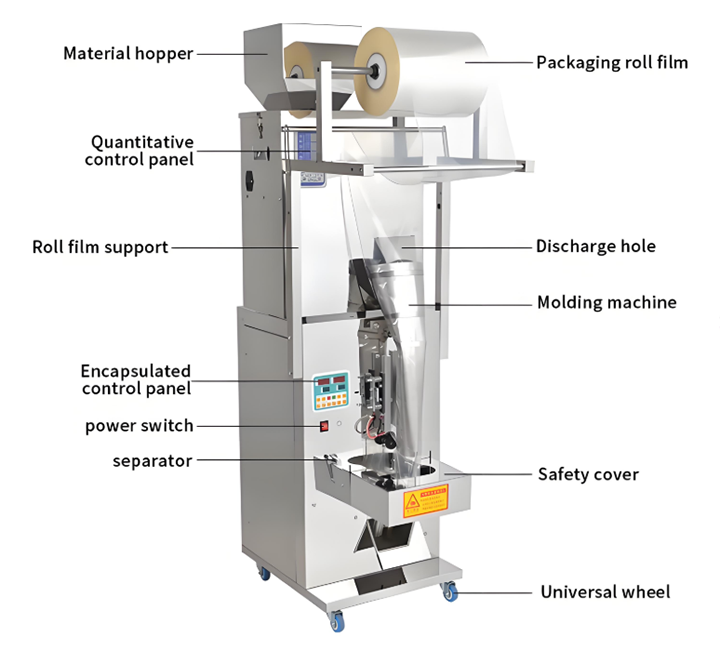

What are the structural components of the fully automatic unloading packaging machine?

Fully automatic unloading packaging machine price depends on its structural components. A fully automatic unloading packaging machine typically consists of six major components: a feeding system, an unloading system, a weighing system, a packaging system, a conveying system, and a control system. The feeding system uses pneumatic conveying, screw conveying, or belt conveying to transport materials from the silo or ton bag to the discharge port. The unloading system automatically controls the discharge valve to accurately deliver the materials to the packaging port. The weighing system uses a high-precision electronic scale to achieve quantitative material control and ensure packaging accuracy. The packaging system automatically completes bag clamping, filling, sealing, or sewing according to the type of bag, such as open-mouth bag, valve bag, or woven bag. The conveying system is responsible for transporting the packaged products to the next process, such as a palletizer or checkweighing system. The control system uses a PLC and is equipped with a touch screen interface, which can set parameters, monitor operating status in real time, and issue abnormal alarms.

Fully automatic unloading packaging machine price

Fully automatic unloading packaging machine price varies depending on the production capacity requirements and the complexity of the system. Below is the price and capacity range from small to large machines.

Small model: The output is about 1-5 tons/hour, suitable for small and medium-sized enterprises, small production lines or pilot plants. Compact structure, small footprint, suitable for multi-variety, small batch material unloading tasks. Its price range is roughly US$8,000-15,000;

Medium-sized models: The output range is 5-15 tons/hour, suitable for medium-sized industrial application scenarios such as chemical, grain processing, and feed production. This type of equipment has a high degree of automation, stable operation, and higher packaging accuracy. The price is generally between US$15,000-35,000;

Large models: The output can reach 15-30 tons/hour or even higher, especially suitable for heavy industrial enterprises that require 24-hour continuous operation, such as cement plants, large feed processing plants, and bulk bulk material export enterprises. This type of equipment is fully functional, supports a variety of packaging forms, and has more complete automation and intelligent configurations. The price is usually around US$35,000.

What materials are suitable for the fully automatic unloading packaging machine?

Although the Fully automatic unloading packaging machine price varies depending on the type of equipment, this type of equipment has good versatility and is suitable for material handling in various industries, including but not limited to the following types:

In the chemical industry, Fully automatic unloading packaging machine is suitable for unloading of various chemical raw materials such as fertilizers, PVC particles, calcium carbonate, titanium dioxide, etc., ensuring accurate material transportation and avoiding cross contamination. In the grain industry, it can handle agricultural products such as corn, rice, wheat, beans, etc., to ensure grain quality and reduce manual operation. In the building materials industry, it is suitable for unloading powdered materials such as cement, lime powder, dry mortar, bentonite, etc., to help the smooth operation of the production line. In the feed industry, it can unload pellet feed, premix and additives to ensure feed quality. Different materials have different requirements for unloading methods, dustproof seals, conveying speeds and packaging forms. Therefore, Fully automatic unloading packaging machine often needs to be customized according to material characteristics during design.

Factors affecting the price of Fully automatic unloading packaging machine

The higher the level of automation of the equipment, such as if it has functions such as automatic weighing, sealing, detection, and palletizing, the higher the price will naturally be; the number of packaging bags per minute, unloading efficiency, etc. directly affect productivity, and the price of high-speed equipment is higher than that of ordinary equipment; different models suitable for powders, granules or liquids have different structural designs and material requirements, and the price difference is large; if the parts in contact with the material are made of 304 or 316L stainless steel or corrosion-resistant materials, the cost will increase significantly; PLC brands (such as Siemens, Mitsubishi, Omron) and configuration levels such as sensors and servo motors affect the price of the entire machine; non-standard customization based on the customer's production line layout, packaging specifications or interface methods will increase design and manufacturing costs.

As an intelligent and highly automated packaging equipment, Fully automatic unloading packaging machine meets the dual needs of industrial production for efficiency and precision. It is widely used in the unloading and packaging of granules, powders and small block materials. The structure consists of six systems: loading, unloading, weighing, packaging, conveying and control, covering small, medium and large specifications. Its production capacity is generally between 500 kg/hour and 3000 kg/hour. Depending on the processing output, the Fully automatic unloading packaging machine price ranges from US$8,000 to US$30,000. Manufacturers can flexibly select according to their own needs.