Which is better PU or PVC conveyor belt?

Friday December-05 2025 17:23:14

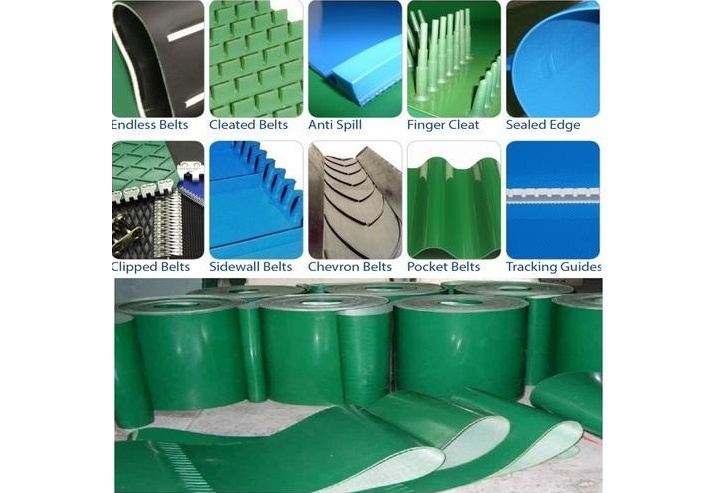

PU and PVC conveyor belts are two common types of conveyor belts. Both provide for the smooth movement of materials, but each possesses unique material properties that lead to differences in performance under different operating conditions. PU conveyor belts are renowned for their outstanding wear and oil resistance, making them particularly suitable for handling abrasive or greasy materials. Their excellent hygienic properties also make them an ideal choice for demanding industries such as food processing. pvc belt conveyor , on the other hand, are favored for their versatility and excellent chemical resistance, providing a stable and reliable solution for many common material handling scenarios.

Which is better, a PU conveyor belt or a PVC conveyor belt?

Advantages of PU conveyor belts

Polyurethane (PU) conveyor belts offer excellent durability, chemical resistance, and hygiene, but are generally more expensive than materials like PVC conveyor belts. Their main advantages include:

PU conveyor belts are made from durable materials that can withstand high-intensity abrasion, cutting, and tearing, making them suitable for conveying heavy or sharp materials in industries such as mining, construction, and waste management. PU conveyor belts are resistant to greases, solvents, and various chemicals, resisting corrosion and degradation. Therefore, they perform exceptionally well in industrial environments such as the automotive and chemical industries. PU itself is non-toxic and odorless, with a smooth, non-porous surface that is not easily stained and is easy to clean and disinfect. This makes it a preferred material for industries with stringent hygiene standards, such as food processing and pharmaceuticals. The flexibility of PU conveyor belts allows them to adapt to complex, curved conveyor systems, which is crucial for production lines requiring precise synchronization and frequent turns.

Advantages of PVC conveyor belts

PVC conveyor belts have become a popular choice for many light and medium-duty material conveying applications due to their cost-effectiveness, durability, and high safety. Their main advantages include:

Compared to conveyor belts made of materials such as rubber or polyurethane (PU), PVC conveyor belts are less expensive to manufacture, making them a reliable choice for many cost-sensitive applications. PVC has excellent chemical and moisture resistance, making it resistant to corrosion and moisture. Many PVC conveyor belts also feature flame-retardant and antistatic properties, effectively reducing the risk of fire and static electricity. Therefore, they are favored in safety-critical industries such as coal mining and electronics. PVC conveyor belts have a smooth surface that does not easily attract dirt, making cleaning and maintenance relatively easy. PVC conveyor belts are lightweight, effectively reducing the energy consumption of conveying systems. Furthermore, their good operational stability ensures smooth material transport during the process, minimizing material damage.

Comparison table of PU or PVC conveyor belt

| Feature | PU Conveyor Belt | PVC Conveyor Belt |

|---|---|---|

| Cost | Higher | Lower, cost-effective |

| Flexibility | Excellent, very soft, good elasticity | Fair, relatively stiff, poor elasticity |

| Abrasion Resistance | Excellent, far superior to PVC | Good, meets general usage requirements |

| Chemical/Oil Resistance | Outstanding, resistant to most mineral oils, greases, and solvents | Poor, prone to aging, hardening, and cracking in oil/solvent environments |

| Heat Resistance | Fair, typically -10℃ to +80℃ | Slightly better, typically -10℃ to +90℃ (special formulations can be higher) |

| Flexibility | High, suitable for small rollers and complex drive designs | Lower, requires larger roller diameters to avoid excessive bending |

| Temperature Range | -10℃ to +80℃ (short-term up to 110℃) | -10℃ to +90℃ (special types from -40℃ to +120℃) |

| Hygiene | Excellent, non-toxic, odorless, complies with FDA/USDA certifications, easy to clean, resistant to bacterial growth | Fair, food-grade PVC requires specific certification, surface micropores can trap dirt |

| Load Capacity | Medium to Good | Good to Excellent, high tensile strength, suitable for heavier loads |

| Typical Applications | Food processing (bakery, confectionery, meat), packaging, precision electronics, tobacco industry, oil-resistant environments | Logistics & parcel sorting, general packaging, building materials, agriculture, general manufacturing, non-oil item transport |

How to Choose Between PU and PVC Conveyor Belts?

When choosing between PU and PVC conveyor belts, the key is to decide based on the specific application and requirements. While both are commonly used, their material properties and application ranges differ significantly.

Application Environment and Material Type

If the conveyor belt needs to transport grease, solvents, or various chemicals, PU is the better choice. It has excellent oil and chemical resistance and is not easily corroded. Furthermore, PU conveyor belts have extremely high abrasion resistance and cut resistance, making them suitable for transporting heavy, sharp, or abrasive materials such as construction waste and ores. If the application environment is relatively mild, primarily for transporting light to medium-weight, non-corrosive materials, PVC conveyor belts are usually sufficient. They are resistant to common chemicals and moisture, but have poor resistance to grease.

Hygiene and Food Safety Requirements

In industries with stringent hygiene standards, such as food processing, PU conveyor belts are the preferred choice. PU is non-toxic and odorless, with a smooth surface that is easy to clean and disinfect, and meets food-grade standards. Although some food-grade PVC conveyor belts are available on the market, their oil resistance is not as good as PU. PU conveyor belts generally perform better when conveying oily materials such as meat and baked goods.

Cost and Budget Considerations

The biggest advantage of PVC conveyor belts is their lower cost. Due to manufacturing processes and material properties, PU conveyor belts are generally more expensive than PVC conveyor belts. However, considering their longer service life and lower maintenance requirements, PU conveyor belts may offer better long-term economic benefits in certain high-load applications.

Other Performance Considerations

PU conveyor belts typically maintain good flexibility and performance over a wider temperature range, including low-temperature environments, while PVC conveyor belts may become brittle at low temperatures. Many PVC conveyor belts have flame-retardant and anti-static properties, which are important for safety-critical industries such as coal mining and electronics manufacturing. PU conveyor belts offer greater flexibility and resilience, making them more suitable for conveyor systems with frequent turns or complex paths.

How to purchase PU conveyor belts and PVC conveyor belts?

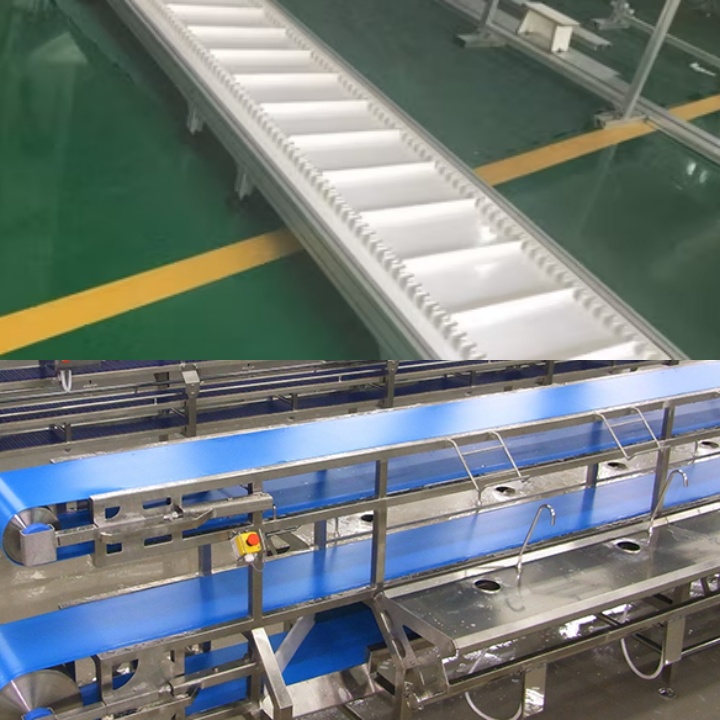

When purchasing, you can choose conveyor belts manufactured by Machrise. The machine can transport bulk or finished materials such as biscuits, meat, pharmaceuticals, chemical powders, precision electronic components, grains, coal, packaging materials, and finished product boxes. Customization options are also available, including wider belts, safety markings, color separations, or magnetic features. Please tell us your ideas, and we will recommend or customize a model for you.

There's no absolute superiority or inferiority between PU and PVC conveyor belts; the only consideration is whether they're suitable for specific applications. When choosing between the two, focus on your actual production needs. If your production line involves high-abrasion, handling sharp materials, or needs to meet strict food hygiene standards, then the characteristics of a PU conveyor belt may better meet the requirements. Conversely, if the operating conditions are relatively routine, the materials are not highly corrosive, and there are no high demands on the specific performance of the conveyor belt, then a PVC belt conveyor may offer a suitable alternative.