Powder Vacuum Loading Machine

Powder Vacuum Loading Machine is an automated conveying device based on the vacuum principle, designed specifically for bulk materials such as powders and granules. It achieves rapid, dust-free material transfer through a sealed pipeline.

Dimensions (L*W*H): Varies depending on the specific model

Material: Stainless steel/Carbon steel

Voltage: 220V/380V/415V or custom-made

Customization: Acceptable

Type: Pneumatic/Electric/Continuous

Core Components: Motor, bearings, gears, pump, gearbox, engine

Applications: Conveying flour, wheat flour, sugar, milk powder, seasonings, coffee powder, plastic powder, and other materials.

What is a Powder Vacuum Loading Machine?

Powder Vacuum Loading Machine is an automated conveying device based on the vacuum principle. It is primarily used to convey and transfer powders of various types and densities. It completely solves the problems of low efficiency, high dust pollution, and high risk of cross-contamination associated with traditional manual feeding, making it the preferred loading equipment for various industries. Furthermore, it can be customized to suit the customer's production site and seamlessly integrated with other equipment to ensure rapid production.

What are the different types of powder vacuum loading machines?

Powder vacuum loading machines are available in a wide variety of types. They are divided into electric and pneumatic models, split and integrated structures, and standard, explosion-proof, and sterile models, meeting the powder conveying needs of various industries.

Intermittent Vacuum Loaders:Composed of a vacuum system, backflush system, filtration system, feed butterfly valve, and discharge butterfly valve. Explosion-proof models can be used to load reactors or mixing tanks with highly reactive internal media, following an automatic cycle of suction, discharge, and backflush.Continuous Conveying

Vacuum Loaders:Utilizing a vacuum generator to generate a high vacuum, creating a negative pressure airflow, they convey granular and powdered materials. The entire conveying process is free of electrical and fire sources, static electricity, and explosion-proof.

What are the advantages of a powder vacuum loading machine?

Powder vacuum loading machines offer significant advantages: fully enclosed conveying and dust control, meeting stringent standards; automated operation saves labor and delivers high efficiency; they are compatible with a wide range of powders and can be customized with explosion-proof features.

Fast loading: Powder vacuum loaders offer extremely fast conveying speeds, capable of completing large quantities of powder in 1-2 minutes, significantly improving production efficiency. Leakage Prevention: The fully enclosed pipeline conveying design eliminates dust leakage at the source, effectively preventing environmental pollution and reducing dust in the workshop, significantly improving the working environment for workers.

Precise and Controllable: Leveraging an advanced intelligent control system, operators can precisely adjust the conveying speed and volume based on the characteristics of different powder materials and production requirements, achieving accurate feeding and effectively reducing material waste.

Widely Compatible: The Powder Vacuum Loader can easily handle both common powders with good flowability and specialized powders with high viscosity and prone to agglomeration.

Flexible Compatibility: It can be connected to equipment such as mixers, packaging machines, and reactors to meet diverse production needs.

Powder Vacuum Loading Machine Technical Parameters

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

How does the Powder Vacuum Loading Machine work?

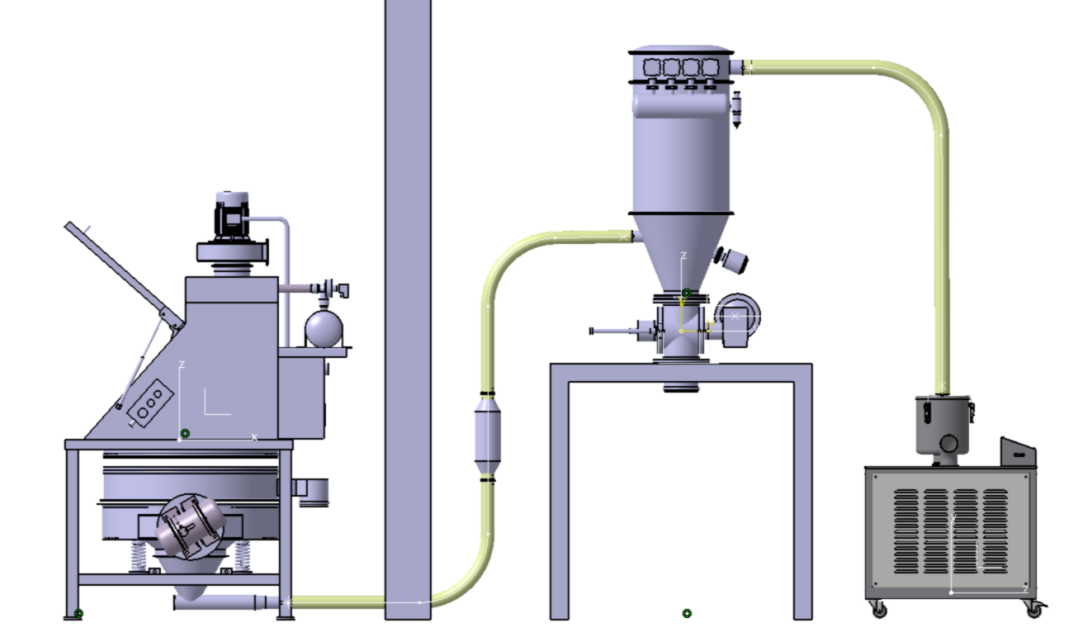

The Powder Vacuum Loading Machine operates based on the principle of negative pressure conveying. A vacuum pump extracts air from the pipeline and hopper, creating negative pressure. The pressure differential then draws powder into the pipeline through the suction port, creating a steady flow of material into the hopper. During the process, air-material separation technology is crucial. A rapid filter intercepts powder, retaining it in the hopper while air is exhausted. Some equipment is equipped with a cyclone separator to further separate fine particles, ensuring clean exhaust air.

What powders can the Powder Vacuum Loading Machine mix?

Powder vacuum loaders can precisely mix APIs and excipients in the pharmaceutical industry, flour and additives in the food industry, pigments and fillers in the chemical industry, and battery material powders in the new energy sector.

Pharmaceutical Industry: The pharmaceutical production process places stringent requirements on material cleanliness and safety. These machines can precisely convey API powders, drug powders, excipient powders, and more. In pharmaceutical production workshops, powder vacuum loaders precisely deliver various powdered materials to mixing, granulating, and tableting equipment.

Food Industry: In food production, powder vacuum loaders can be used to convey various food ingredients, including flour, milk powder, powdered sugar, starch, and seasonings. They can also automatically and quickly deliver materials to mixing and forming equipment in processes such as baked goods production, reducing manual intervention and labor costs. Chemical Industry: Chemical raw materials are often corrosive, flammable, and explosive. Powder vacuum loaders, through their use of specialized materials and safety designs, can safely transport various chemical powders, pigments, dyes, and more.

Plastics Industry: During the plastics production process, powder vacuum loaders can precisely deliver plastic additive powders, masterbatches, and other materials to extruders, injection molding machines, and other equipment, avoiding material waste and contamination and improving the quality of plastic products.

How to Choose a Powder Vacuum Loading Machine?

When selecting a powder vacuum loader, consider the material characteristics, conveying volume, and distance, matching the power source, structure, and functionality, while balancing regulatory compliance and production suitability.

Selecting by Power Source: Electric vacuum pump-driven powder vacuum loaders offer stable vacuum levels and high conveying efficiency, making them suitable for applications requiring high continuous operation capabilities. Pneumatic vacuum pump models, powered by compressed air, generate no sparks, and offer excellent inherent explosion-proof properties. They are ideal for conveying flammable and explosive powders in industries like the chemical and new energy industries.

Select by structure: Split models feature separate components like the vacuum pump and hopper, allowing for flexible piping layout and enabling long-distance conveying of up to 50 meters horizontally and 20 meters vertically, making them suitable for inter-regional material transfer within large production lines. Integrated models offer high integration, a small footprint, and easy installation and movement, making them ideal for compact workshops or short-distance, small-batch conveying.

Select by features: The standard model is suitable for general powder conveying applications requiring no special requirements, offering a cost-effective solution. Equipped with static elimination and an inert gas shielding system, the aseptic model utilizes 316L stainless steel, features an electrolytically polished interior, and supports in-line sterilization. It is ideal for conveying sterile materials such as APIs and vaccine powders in the pharmaceutical industry.

What equipment can the Powder Vacuum Loading Machine be used with?

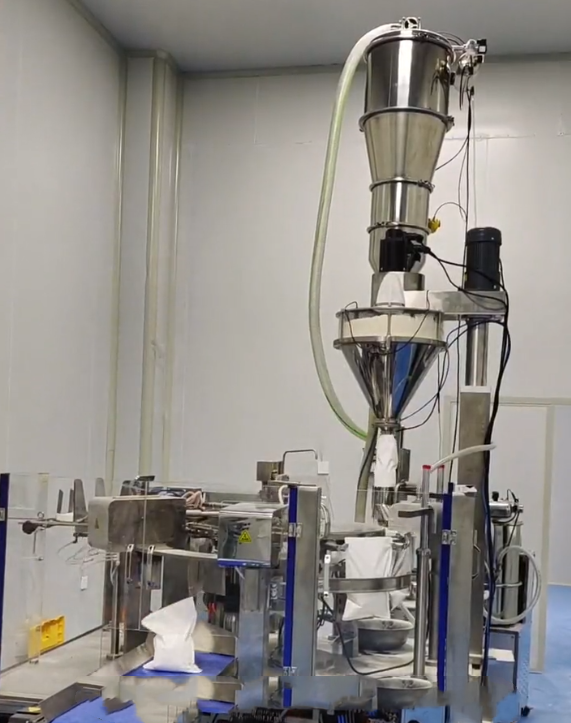

The Powder Vacuum Loading Machine seamlessly integrates with equipment such as screeners, packaging machines, and mixers. It can be integrated with screeners for dust-free grading, integrated with packaging machines for accurate metering, and integrated with mixers for improved batching efficiency. Powder vacuum loaders seamlessly integrate with screening machines, packaging machines, mixers, and other equipment to form efficient automated production lines.

Combined with screening machines: The loaders precisely convey powder to the screening equipment inlet. This fully enclosed conveying method eliminates dust contamination before screening. Intelligent control matches the screening speed to prevent material accumulation or feed breakage, making them particularly suitable for the grading and screening of APIs in the pharmaceutical industry.

Combined with packaging machines: The load rate automatically adjusts according to packaging specifications, enabling continuous feeding from the storage silo to the packaging machine, reducing manual feeding steps.

Combined with mixers: Multiple powder raw materials can be sequentially fed to the mixer according to the recipe ratio. The load rate and mixing time are linked and controlled by a PLC system, improving batching accuracy and mixing uniformity, shortening production cycle times.

Powder Vacuum Loading Machine Customer Solutions

Why choose us as your Powder Vacuum Loading Machine supplier?

Choosing our Powder Vacuum Loading Machine allows us to provide comprehensive services and one-stop customized production solutions to help you solve your powder feeding problems.

Customized Precision Adaptation: In-depth analysis of powder characteristics such as viscosity and density allows for tailored conveying solutions, ensuring stable conveying of both high-viscosity agglomerated powders and low-density, lightweight powders.

High-Quality Core Guarantee: Selected core components are branded to ensure long-term, efficient operation and minimize the risk of failure.

Full-Life Worry-Free Service: From initial solution design and on-site installation and commissioning to regular maintenance and component replacement, we provide one-stop, full-lifecycle support, ensuring worry-free production.

With its outstanding advantages of high speed, energy efficiency, precision, and compatibility, the Powder Vacuum Loading Machine plays an indispensable role in production across various industries, providing a reliable solution for companies to optimize production processes, improve efficiency, and ensure product quality.