Pneumatic Vacuum Loading Machine

Pneumatic Vacuum Loading Machine uses air pressure differentials to transport powders and granular materials. This motor-free, streamlined machine features explosion-proof, oil-free, and cleanroom features, enabling sealed, dust-free conveying. Maintenance is simple, and installation is flexible.

Belt Material: Stainless Steel

Voltage: 380V / Customizable

Frame Material: 304, 316 Stainless Steel / Carbon Steel

Conveying Capacity: 10 kg - 10 tons/hour

Length: Customizable, 1-100 meters

Conveyed Materials: Granular and powdered products

Conveying Method: Pneumatic

Applicable Industries: Widely used in the food, pharmaceutical, chemical, and new energy industries, conveying powders and granular materials. It is particularly well-suited for cleanrooms, explosion-proof environments, and small-batch transfers in laboratories.

What is Pneumatic Vacuum Loading Machine?

Pneumatic Vacuum Loading Machine is a new material conveying equipment driven by compressed air. It is different from traditional electric vacuum pump models. It does not require additional motors, reduces the size and noise of the equipment from the root, adapts to powders, particles and other materials, and has customized options such as explosion-proof and anti-static. The characteristic of no power drive is especially suitable for chemical explosion-proof workshops, temporary work stations without power supply, etc., providing flexible and safe solutions for material transfer on the production line.

What are the advantages of Pneumatic Vacuum Loading Machine?

The pneumatic vacuum feeder is powered by compressed air, does not require a motor, has strong explosion-proofness, simple structure, easy maintenance, and no motor maintenance cost; it is fully airtightly conveyed, meets the clean standards, and can also flexibly deal with temporary stations.

Convenient power: Powered by conventional compressed air in the factory, there is no need to install an additional electric vacuum pump to avoid the problem of motor land occupation and wiring. It is especially suitable for chemical explosion-proof workshops and no temporary power supply stations.

Low noise energy saving: high-frequency noise generated by motor operation, low working noise, and no maintenance needs such as motor wear and lubricant replacement.

Clean and oil-free: The vacuum generator is free of oil and dirty production, and it is matched with stainless steel contact material parts and coated filter element. After the gas material is separated, the air is clean and free of impurities, meeting the food and pharmaceutical industries and other clean standards.

Small size: without motors and large pumps, the volume of the entire machine is 40% smaller than that of the motor model with the same production capacity. It can be installed on wall or brackets, and is suitable for narrow space in the workshop.

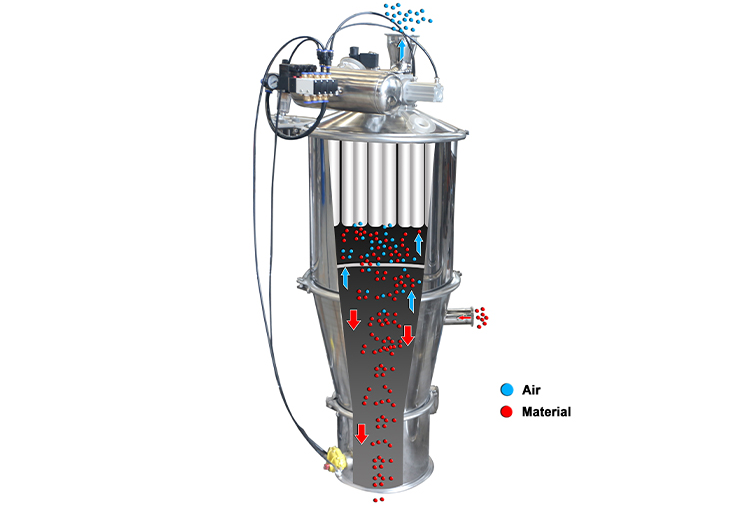

How does Pneumatic Vacuum Loading Machine work?

The core of the pneumatic vacuum feeder uses compressed air as the power source, and the pressure energy of compressed air is converted into negative pressure energy through the vacuum generator: the compressed air enters the nozzle of the vacuum generator and is sprayed at high speed, taking away the air in the generator cavity, so that a stable negative pressure is formed in the connected conveying system. At this time, the external atmospheric pressure forms a pressure difference between the system negative pressure, and the material is sucked into the conveying pipeline from the suction port and enters the separation hopper with the airflow; in the hopper, the gas mixture is filtered through a high-efficiency filter element, and the material falls into the target equipment due to gravity. The filtered clean air merges with the exhaust gas discharged from the vacuum generator and is discharged from the exhaust port.

What are the main structures of Pneumatic Vacuum Loading Machine?

The pneumatic vacuum feeding machine is mainly composed of a vacuum generator, suction component, separation hopper, discharge valve and control system. Each component coordinates to achieve the separation of negative pressure suction and gas.

Power core: Vacuum generator: Using compressed air as the driving source, high-speed air flow is injected through the internal nozzle, the air in the system is discharged to form a stable negative pressure, and is usually directly connected to the compressed air pipeline.

Material conveying assembly: includes suction port and conveying pipeline. The suction port has many sealing rings to ensure sealing; the conveying pipelines are mostly made of stainless steel, and different diameters are selected according to the conveying distance and material characteristics.

Gas material separation unit: separation hopper: As the core for the temporary storage of materials and the separation of gas materials, it is equipped with a high-efficiency filter element inside to intercept materials and allow air to pass through. The bottom of the hopper is usually equipped with unloading.

Control components: consist of a pneumatic control box and sensor. The pneumatic control box adjusts the compressed air pressure and controls the start and stop of the vacuum generator; the pressure sensor monitors the negative pressure of the system, and the material level sensor senses the height of the material in the hopper to ensure the automatic start and stop and circulating operation of the equipment.

Pneumatic Vacuum Loading Machine Parameters

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

What are the prices of different models of Pneumatic Vacuum Loading Machine?

The price of Pneumatic Vacuum Loading Machine varies significantly depending on the model. Small basic model, suitable for experiments or small workshops, low conveying volume, single function, mostly made of ordinary plastic or carbon steel, and the price may be as low as $800 - $1,500. The medium-sized standard model is made of 304 stainless steel, with moderate conveying volume and basic functions such as pulse cleaning. It can meet the needs of general food and chemical industries, and the price is a little higher than that of ordinary ones. Large customized models, if used in high-demand industries such as pharmaceuticals, use 316L stainless steel, equipped with explosion-proof and sterile functions, has a high conveying volume and a long conveying distance, and is priced higher.

What are the application scenarios of Pneumatic Vacuum Loading Machine?

Pneumatic vacuum feeding machines are widely used in food, pharmaceutical, chemical, new energy and other industries. They can transport powders and particulate materials, especially suitable for small batch transportation in clean workshops, explosion-proof scenarios and laboratories.

Food processing industry: adapted to the transportation of powder/particle materials such as flour, milk powder, cocoa powder, sugar, etc., and can be used for automatic feeding of flour mills from silos to mixers, milk powder mills from storage tanks to packaging machines.

Pharmaceutical industry: For pharmaceutical powders and pharmaceutical granules, the equipment can customize 316L stainless steel material and sterile filter element to meet the cleaning requirements. It is often used for material transportation between pharmaceutical factory ingredients to reactors and tablet presses.

Chemical and Plastics Industry: Suitable for plastic masterbatches, resin powders, pigment powders, chemical additives and other materials, it supports explosion-proof design, and can achieve safe transportation from raw material tanks to extruders and injection molding machines in the explosion-proof workshop to prevent the risk of dust explosion.

New energy and building materials industry: used in lithium battery positive electrode materials, negative electrode materials, cement powder, gypsum powder and other materials. The equipment has wear-resistant pipes and dust removal filters, which can adapt to the transportation of high hardness and high specific gravity materials.

Laboratory and small production scenarios: The small pneumatic vacuum feeder is small in size and does not require external power supply. It can be used for small batch material transfer in university laboratories and small health care workshops, and flexibly adapt to the needs of narrow spaces and temporary workstations.

Pneumatic Vacuum Loading Machine vs Electric Vacuum Loading Machine

| Comparison Dimension | Pneumatic Vacuum Feeder | Electric Vacuum Feeder |

| Power Source | Driven by compressed air to power a vacuum generator (no external vacuum pump required) | Driven by a motor to power a roots pump/vortex pump (motor and cooling system required) |

| Working Principle | Uses the Venturi effect to form negative-pressure airflow, achieving conveying through compressed air energy conversion | he motor drives the impeller to rotate at high speed to generate vacuum, directly sucking materials |

| Performance Characteristics | Strong explosion-proof performance, simple structure, relatively high noise, relatively high energy consumption | High vacuum degree, low noise, energy-saving mode, strong particle passing capacity |

| Application Scenarios | Clean workshops in pharmaceutical/food industries, chemical/hazardous chemical fields, ultra-fine powder conveying | High-density particle conveying, long-distance conveying needs, lithium battery material production |

| Maintenance Cost | Simple maintenance: only regular cleaning of Venturi tube carbon deposits is needed (no motor maintenance required), short filter element service life | Long filter element service life: PTFE coated filter element has a service life of up to 3000 hours; modular design enables quick replacement, high motor maintenance cost |

How to judge whether the working pressure of Pneumatic Vacuum Loading Machine is normal?

To determine whether the working pressure of Pneumatic Vacuum Loading Machine is normal, you can use the three steps of "seeing the instrument, observing the operation, and checking the status".

Look at the vacuum pressure gauge value: The vacuum pressure gauge standard equipped with the equipment will display the negative pressure value in real time. You can refer to the equipment manual. If the value is below the lower limit for a long time, it may be that the seal leaks or the filter element is blocked; if it is higher than the upper limit, it may be that the vacuum generator is faulty or the intake pressure is too high, and it needs to be adjusted in time.

Observe the material conveying status: When the pressure is normal, the material is sucked in at a constant speed from the suction port, and there is no obvious blockage or stuttering in the pipeline, and the hopper is discharged smoothly during unloading; if the material is slow to absorb and cannot be suctioned, it is mostly insufficient negative pressure; if the material is violently impacted and the noise becomes large in the pipeline, it may be that the negative pressure is too high, causing the air flow to be too fast.

Check the equipment seal and exhaust: Check whether the suction port seal ring and pipe interface are damaged and leaked, and observe the exhaust port at the same time. In normal times, there is no dust or abnormal airflow sound. If the exhaust gas is loaded with materials or sounds harsh, it may be caused by abnormal pressure to cause the filter element to fail or the air circuit failure.

Pneumatic Vacuum Loading Machine Suppliers

We focus on the research and development and manufacturing of powder and particulate material processing equipment, and have strong technical strength in the field of Pneumatic Vacuum Loading Machine. Able to customize solutions according to customer needs, from design to after-sales service, comprehensive service. The pneumatic vacuum feeding machine it produces by using compressed air to generate negative pressure through the vacuum generator to realize material transportation. It has a streamlined structure, low noise, and no maintenance. It is widely used in pharmaceutical, food and other industries. It is a trustworthy high-quality supplier. It can also provide screening machines, conveyors, packaging machines, and mixers that can be used in combination, and the source manufacturer is at the source, with discounted prices!

Pneumatic Vacuum Loading Machine has irreplaceable value in special operating conditions due to its unique electrical and explosion-proof characteristics. It is especially suitable for chemical industry, military industry, laboratories and other fields where safety and environmental adaptability requirements are extreme. We provide gas consumption measurement and solution verification services to help you accurately match your needs!