Pharmaceutical Vacuum Loader

Pharmaceutical Vacuum Loader uses negative pressure generated by an oil-free vacuum pump to draw pharmaceutical powders, granules, and other materials from storage. After separation of air and material through a medical-grade filtration system, the loader precisely delivers them to equipment such as reactors and tablet presses.

Material: 304 and 316 stainless steel

Support: CIP/SIP cleaning

Voltage: 80V / Customizable

Conveying Capacity: 10 kg - 10 tons/hour

Length:Customizable, 1-100 meters

Conveyed Materials: Granular and powdered materials

Applicable Materials: Antibiotic powder, vitamin powder, protein powder, pharmaceutical powder, granules, and pills

What is a Pharmaceutical Vacuum Loader?

Pharmaceutical Vacuum Loader is a material transfer device specifically developed for the pharmaceutical industry, featuring negative pressure containment conveying. It addresses the challenges of cleanliness, safety, and compliance in the transport of materials such as pharmaceutical powders, sterile granules, and highly active ingredients. This device can be flexibly connected in tandem with multiple formulation machines, mixers, or packaging machines to create automated production lines. It offers high customization, allowing adjustments to materials, capacity, and control systems to meet specific customer needs, adapting to varying cleanliness levels and material characteristics.

What are the advantages of the Pharmaceutical Vacuum Loader?

Constructed of stainless steel, the Pharmaceutical Vacuum Loader uses negative pressure containment to eliminate contamination. Its adjustable length and height, combined with high-precision filtration and automated controls, allows for rapid transfer of APIs and sterile granules, reducing costs, improving efficiency, and ensuring safety.

Compliant with pharmaceutical standards: The Pharmaceutical Vacuum Loader's compliance design far exceeds that of standard equipment. All material-contacting components are constructed of 316L medical-grade stainless steel, eliminating weld dead spots and the risk of material residue. It is also resistant to long-term corrosion from various pharmaceutical excipients, including acids and bases.

Fully Enclosed Conveying: Utilizing the principle of negative pressure enclosed conveying, the entire material process, from intake to conveying to discharge, takes place within enclosed pipes and hoppers, eliminating manual contact and dust leakage.

Dual Aseptic and Explosion-Proof Guarantees: Addressing the diverse safety requirements of the pharmaceutical industry, the equipment features dual protection capabilities. For sterile drug production, it incorporates an integrated online sterilization system, and for conveying flammable and explosive materials, it is equipped with an explosion-proof motor.

PLC Control System: Equipped with a PLC control system and a high-precision weighing module, it enables "quantitative conveying" and precisely matches the required ratios for excipient addition and raw material feeding in pharmaceutical production, preventing unacceptable drug content due to manual weighing errors.

Customized Adaptation: As specialized equipment for pharmaceutical production, it can be customized based on your company's workshop layout and material characteristics. This customized design allows the equipment to seamlessly integrate with existing production lines, eliminating production efficiency impacts caused by equipment compatibility issues.

Pharmaceutical Vacuum Loader Technical Principle

The pharmaceutical vacuum loader uses a vacuum pump to create a negative pressure environment. It utilizes the pressure differential between the inside and outside of the pipeline to draw materials from a storage silo or container into a sealed pipeline and transport them to the target location. Its core process can be divided into three steps.

Starting the vacuum pump: After the vacuum pump is started, the internal pressure of the system rapidly decreases, creating a vacuum environment.

Material Adsorption: Under the action of negative pressure, the material is drawn into the pipeline through the suction nozzle, where it mixes with the airflow to form a gas-solid two-phase flow.

Gas-Solid Separation: After reaching the destination, the material passes through a filter or cyclone separator to separate the gas and solids. The material falls into a storage tank, and the gas is discharged after dust removal.

Pharmaceutical Vacuum Loader Technical Parameters

| Model | Motor Power (KW) | Conveying Capacity (Koh) |

| HCSL - 1 | 1.5 | 400 |

| HCSL - 2 | 2.2 | 600 |

| HCSL - 3 | 3 | 1200 |

| HCSL - 4 | 5.5 | 2500 |

| HCSL - 6 | 5.5 | 3200 |

| HCSL - 7 | 7.5 | 6000 |

| HCSL - 10-6 | 7.5 | 6000 (When the conveying distance is 10 meters) |

| HCSL - 20-5 | 11 | 5000 (When the conveying distance is 20 meters) |

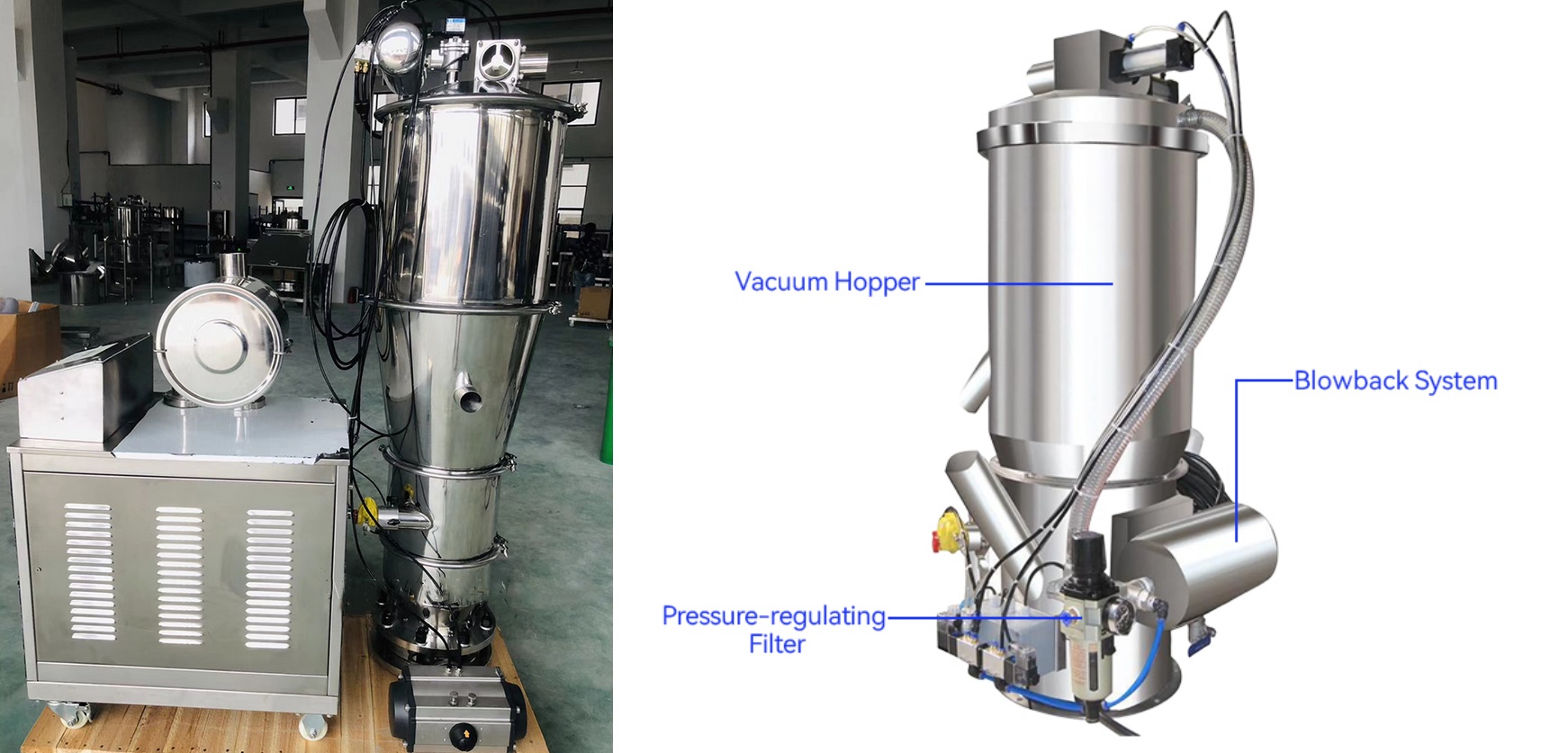

Pharmaceutical Vacuum Loader Components

The Pharmaceutical Vacuum Loader uses negative pressure pneumatic conveying technology to automatically convey powders and granular materials. Its core structure consists of a vacuum pump, filtration system, control system, conveying pipeline, and auxiliary components. These components work together to ensure efficient, clean, and safe material transportation.

The vacuum pump:It is the power source of the pharmaceutical vacuum loader. It extracts air from the system to create a stable negative pressure of 0.4-0.6 bar, providing critical energy for material suction and conveying.

The filtration system:It is critical for ensuring material purity and equipment life. It uses various filter types to achieve precise air-material separation.

The control system:Based on a PLC, it allows preset parameters such as conveying time and backflush frequency, enabling automated equipment operation and significantly reducing manual intervention. Combined with an automatic material level control device, a sensor monitors the material level in the hopper and automatically starts and stops the vacuum pump, enabling unmanned operation.

Conveying Pipes and Auxiliary Components:The conveying pipe is made of wear- and corrosion-resistant stainless steel, connecting the suction nozzle to the target equipment. The suction nozzle can be designed to suit the characteristics of different materials, such as powders and granules. The vacuum hopper can store materials in a sealed manner to prevent contamination. The pneumatic discharge gate device allows precise discharge of materials through pneumatic control once the materials reach the target location.

What types of filters are available for pharmaceutical vacuum loaders?

The filter is a core component in a pharmaceutical vacuum loader, and its choice of filter type directly impacts conveying efficiency, material purity, and equipment life. The pharmaceutical industry's stringent requirements for cleanliness, corrosion resistance, and explosion resistance are crucial.

Membrane-coated bag filters: Utilizing PTFE membrane technology, they intercept fine dust and microorganisms from pharmaceutical raw materials. Their smooth surface resists dust adhesion, supports backflushing or pulse cleaning, and features an anti-static design to eliminate static electricity risks. They are suitable for conveying flammable and explosive materials.

Stainless steel membrane filters: Made of stainless steel, they offer strong acid and alkali corrosion resistance and high temperature tolerance, and can withstand sterilization. They are suitable for conveying chemical-containing materials such as traditional Chinese medicine extracts and biopharmaceutical fermentation broths.

PE-coated bag filters: Made of polyester fiber, they are coated with a high-precision polytetrafluoroethylene microporous membrane, creating a "surface filtration" structure. Their filtration accuracy meets the requirements for intercepting ultrafine dust and microorganisms found in the pharmaceutical and food industries. The smooth surface of the PTFE membrane resists dust adhesion, and combined with pulse backflushing or pneumatic cleaning systems, particles can be quickly removed from the filter surface.

Titanium filters: They offer exceptional corrosion resistance, making them resistant to highly corrosive media such as concentrated hydrochloric acid and aqua regia. They also offer the advantages of being lightweight and biocompatible. These filters are designed for extreme applications, such as preventing radiation degradation in radiopharmaceutical production and combating chemotherapy drug corrosion during the transportation of anticancer drug raw materials, ensuring stable equipment operation and operator safety.

Which filter type is best suited for pharmaceutical vacuum loaders?

Pharmaceutical companies must comprehensively select a filter based on material characteristics, process requirements, and budget. Economical membrane filter bags are preferred for conveying general pharmaceutical powders; stainless steel filters are recommended for chemical raw materials or high-temperature sterilization; membrane filters are suitable for high-precision applications such as sterile preparations and inhalation preparations. Titanium filters are essential for extreme conditions such as those involving strong corrosion and radiation. By precisely matching filter types, companies can optimize production efficiency, product quality, and cost control.

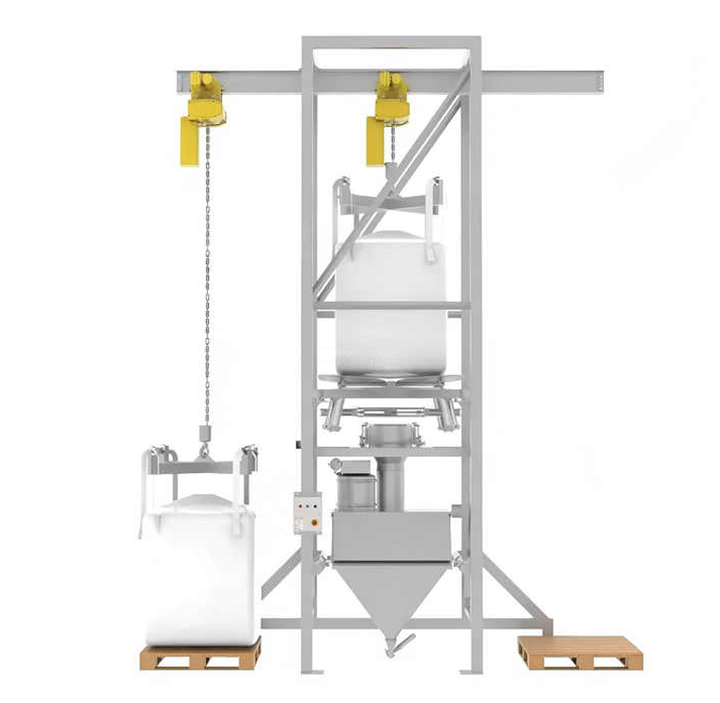

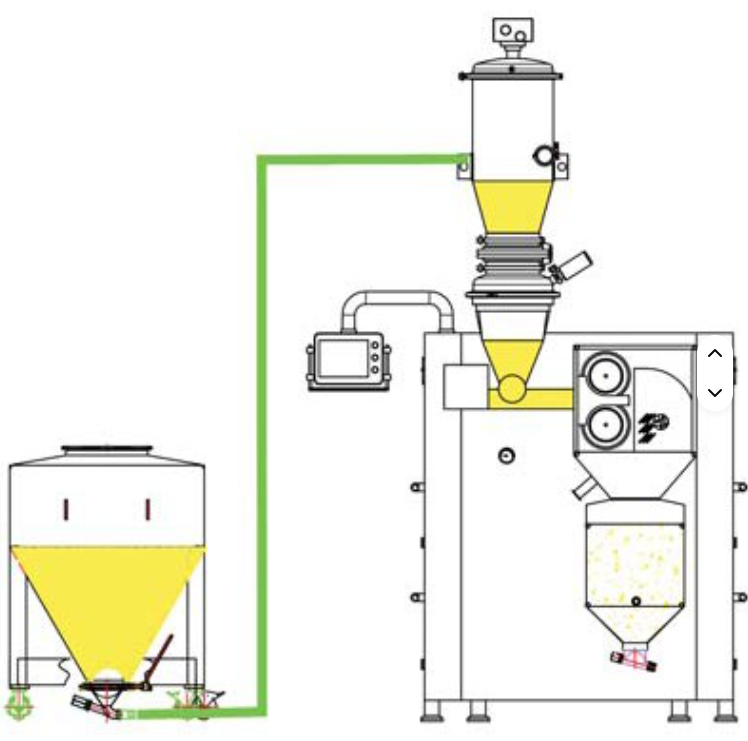

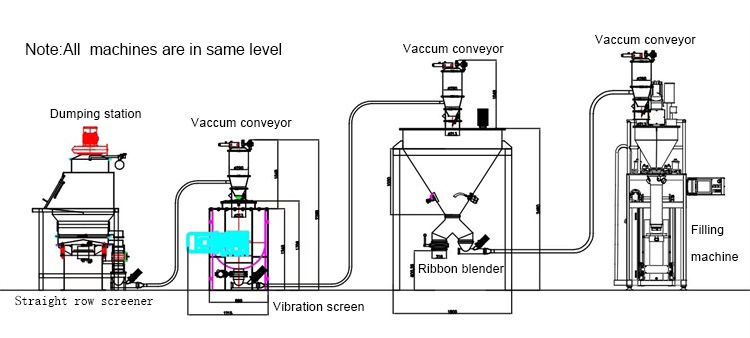

The Pharmaceutical Vacuum Loader can be used in tandem with multiple devices.

In pharmaceutical production, combining a screening machine, mixer, Pharmaceutical Vacuum Loader, and packaging machine in tandem creates an efficient, closed, automated production line, seamlessly integrating the entire process from raw material pretreatment to finished product packaging.

As raw material pretreatment equipment, the screening machine, equipped with a vibrating or rotary screen, removes lumps, impurities, and oversized particles, ensuring uniform particle size for improved subsequent mixing. A sealed hood is also installed to prevent dust leakage. Subsequently, a pharmaceutical vacuum loader provides closed-loop conveying. Made of stainless steel, it automatically starts and stops according to the material level in the mixer, allowing unmanned operation. It transfers the screened material from the screening hopper to the mixer. The mixer is responsible for mixing various raw materials in proportion to ensure uniformity. Depending on the material characteristics, a V-shaped, three-dimensional motion, or double-cone mixer can be selected, equipped with a sealed feed port to connect to the vacuum loader. Another pharmaceutical vacuum loader performs secondary conveying, equipped with a pressure-resistant vacuum pump for long-distance transport, transferring the mixed material from the mixer to the packaging machine hopper. Finally, the packaging machine, which can be an automatic bottling line, bag filling machine, or blister packaging machine, completes the quantitative packaging of the materials and the packaging of the finished products.

Pharmaceutical Vacuum Loader Customization Case Studies

From pharmaceutical companies using 316L stainless steel vacuum loaders for corrosion-resistant antibiotic transportation, to biopharmaceutical companies using separation equipment to prevent cross-contamination, to traditional Chinese medicine companies using custom models to transport extracts, the Pharmaceutical Vacuum Loader is customizable on demand, helping companies improve efficiency, reduce costs, and maintain compliance.

API companies:Transferring antibiotic powder to reactors requires equipment that is corrosion-resistant, meets hygiene standards, and prevents dust contamination. This customized solution utilizes a 316L stainless steel vacuum loader, which is both acid- and alkali-resistant. A 0.22μm membrane filter ensures sterile transportation, while an explosion-proof design eliminates the risk of static electricity.

Biopharmaceutical companies:Transferring highly active anticancer drug raw materials presents the challenge of cross-contamination between batches and requires equipment that supports CIP/SIP cleaning. The customized, separate vacuum loader features a hopper and main unit, allowing for quick disassembly and cleaning. Equipped with a highly corrosion-resistant titanium filter, it can withstand sterilization at temperatures up to 121°C. A pneumatic discharge gate ensures residue-free discharge.

Traditional Chinese medicine companies:Transferring herbal extracts to concentration tanks requires equipment that is resistant to high temperatures, corrosion from herbal ingredients, and meets food-grade hygiene standards. The customized, food-grade stainless steel vacuum loader is constructed from 304 stainless steel, polished to Ra ≤ 0.4μm. It features high-temperature-resistant silicone seals to support transfer temperatures exceeding 100°C, and a new air supply line prevents air bubbles from causing material leakage.

How much does a pharmaceutical vacuum loader cost?

Our pharmaceutical vacuum loader starts at $2,000, but the actual price fluctuates depending on various factors. Regarding material, choosing 316L medical-grade stainless steel increases the cost due to its high corrosion resistance and processing difficulties. Standard 304 stainless steel is more affordable. Equipment specifications and features also influence price. Small, basic models meet simple conveying needs and are affordable. Larger models with CIP (Clean in Place, In-Place In-Place) cleaning and SIP (Stovetop In-Place Sterilization), or those suitable for explosion-proof environments and equipped with precise weighing and automated linkage capabilities, can cost tens of thousands of dollars due to their complex technology and advanced features.

The Pharmaceutical Vacuum Loader, with its superior sterility assurance, flexible multi-device integration capabilities, and high degree of customization, has established itself as an indispensable component in modern pharmaceutical production lines. It is not only a technological benchmark for achieving closed, high-speed, and dust-free conveying, but also a solid foundation for pharmaceutical companies to improve compliance, production efficiency, and intelligent capabilities.