High speed packaging machine

Saturday January-31 2026 16:34:27

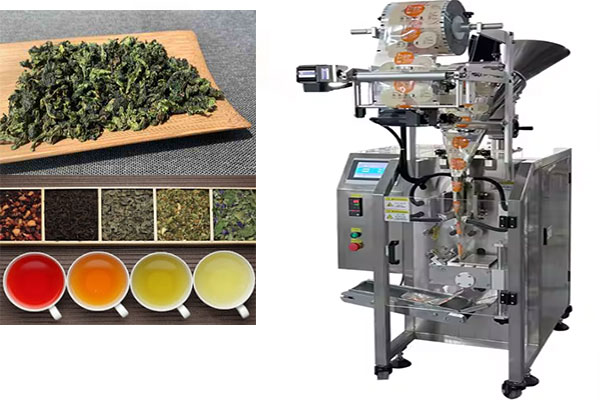

High speed packaging machine is a high-efficiency automated packaging equipment that integrates automatic feeding, metering, bag making, filling, sealing and cutting. It is mainly used to meet the high requirements of packaging speed and precision of large-scale production lines, and is suitable for food, medicine, chemical, daily chemical and other industries. Compared with ordinary packaging equipment, high-speed packaging machine is faster and more stable in performance. It is one of the key equipment to improve production capacity and efficiency in modern smart factories.

Technical parameters of High speed packaging machine

| High Speed Automatic VFFS Packing Machine | ||

| Model: JW-KGS600 | ||

|

spec |

Packing Speed | 300-800 bags/min(depends on the bag and filling material) |

| Filling capacity | ≤20ml | |

| Pouch length | 30-110mm(Length should be spec) | |

| Pouch width | 30-100mm | |

| Sealing type | three sides sealing | |

| Film width | 60-200mm | |

| Max.rolling diameter of film | ¢450mm | |

| Dia of film inner Rolling | ¢75mm | |

| Power | 7kw, three-phase five line, AC380V, 50HZ | |

| Compressed air | 0.4-0.6Mpa, 150NL/Min | |

| Machine dimensions | (L)2100mm x(W)1000mm x(H)2000mm | |

| Machine weight | 1400KG | |

| Remarks: It can be customize for special requirements. | ||

|

Product Application: Various powder and granule flavor, powder pesticides, granule foodstuff, tea, herbal powder and etc. |

||

| Bag Material:Suitable for most complex film packing film in home and abroad, such as PET/AL/PE, PET/PE, NY/AL/PE, NY/PE and so on. | ||

Tips:these parameters can be customized according to user production needs and flexibly adapted to various industrial scenarios.

Working principle of high speed packaging machine

The basic working principle of high speed packaging machine is to coordinate the electronic control system and sensors to drive each working part to realize the continuous packaging process. Taking the roll film automatic forming packaging as an example, the equipment first folds the packaging film into a bag shape through the former, and then seals it by the horizontal and vertical sealing mechanisms. The synchronous metering system accurately puts the material into the bag, and then cuts it through the cutter to realize the output of bags of finished products. The whole process relies on the servo drive system to control the rhythm and achieve high-speed and high-precision operation. High-speed models mostly adopt multi-channel design or parallel conveying mode, which greatly improves the production capacity per unit time.

What are the different types of high speed packaging machine?

High speed packaging machine is mainly divided into the following categories according to the packaging form, material type and application scenario:

Vertical Packaging Machine (VFFS): Suitable for small to medium-sized bag packaging of granules, powders, and liquids, with a production capacity of 40-120 bags per minute. Supports various bag types including three-side seal, back seal, and four-side seal.

Pillow Packaging Machine: Used for continuous packaging of common items such as candy, bread, and masks. High speed, with a production capacity of 200-500 bags per minute. Supports pillow bags and adaptable to various folding packaging methods.

Bag Feeding Packaging Machine: Uses pre-made bags, suitable for various specifications and small batches of products. Production capacity is generally 20-60 bags per minute. Supports various pre-made bag types including back seal, corner pockets, and stand-up pouches.

Heat Shrink Packaging Machine: Suitable for bulk packaging of bottled and boxed products, such as beverages and cosmetics. Production capacity is 10-30 trays per minute. Supports full-size heat shrink film packaging and adaptable to both bulk and single-item packaging.

Vacuum Packaging Machine: Used for food and pharmaceutical preservation, it seals after vacuuming. Production capacity varies from 2 to 20 cycles per minute depending on the model. It supports various vacuum bag types, including flat bags, stand-up pouches, and flexible film/rigid boxes.

Liquid/Paste Packaging Machine: Designed for liquid materials, commonly used in the detergent and seasoning industries. Typical production capacity is 30-80 bags per minute. It supports three-side seal, four-side seal, and stand-up pouches.

Multi-channel High-Speed Packaging Machine: Suitable for small-dose packaging, such as sauce bags and seasoning powders. It boasts high production capacity, reaching 300-1000 bags or more per minute. It supports multi-row back-seal, three-side seal, and other small bag types, suitable for parallel multi-channel packaging.

Each type has its own exclusive application field, and the appropriate model can be selected according to production needs.

High speed packaging machine has become an important equipment for modern production lines to improve packaging capacity with its high efficiency, high precision and high degree of automation. It not only saves labor and improves product consistency, but also can adapt to a variety of bag types and materials. It is a key tool for realizing intelligent packaging in the food, medicine, chemical and other industries. As packaging needs continue to upgrade, high-speed packaging machines will continue to develop in a smarter and more environmentally friendly direction. Reasonable selection and matching use will greatly improve the production efficiency and market competitiveness of enterprises.