Twin Screw Conveyor Prices

Monday July-28 2025 16:06:08

The price of a Twin Screw Conveyor ranges widely depending on its type, handling capacity, conveying distance, and other customized requirements. The cost of a Twin Screw Conveyor can range from $100 for a basic model to $7,000 for a custom, heavy-duty unit. In addition, the amount of material that the Twin Screw Conveyor can handle (such as tonnage or cubic meters per hour), the required conveying length and lifting height, and the requirements for materials (carbon steel, stainless steel, or other special alloys) are all key factors in its pricing system.

What are the types of Twin Screw Conveyors?

The price of a Twin Screw Conveyor is affected by many factors, among which the structural type is one of the important factors that determine the cost. It can be mainly divided into U-shaped trough type and tube type, which have obvious differences in price.

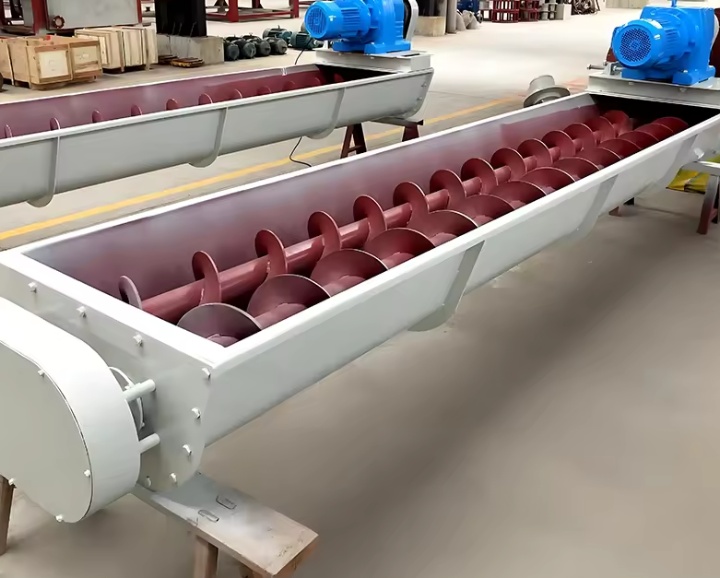

U-shaped trough Twin Screw Conveyor

U-shaped trough Twin Screw Conveyor is a more common and widely used type. Its conveying trough is in the shape of a "U", and the two spiral blades rotate side by side in the trough, pushing the material forward through collaboration.

Features: The structure is relatively simple, open, and easy to observe and clean; it is suitable for conveying various types of bulk materials such as granular, powdery, and small blocks, especially in some occasions where there are no strict sealing requirements.

Price: Generally speaking, the price of the U-groove Twin Screw Conveyor is relatively low and is the basic model on the market. It depends on the length of the conveyor, the diameter of the screw, the material (carbon steel or stainless steel), the motor power, and whether additional customized functions are required (such as linings, cleaning devices, etc.).

Tubular Twin Screw Conveyor

The tubular Twin Screw Conveyor completely encloses the spiral blades in a circular tubular shell. The material is pushed by the spiral in a closed pipe and transported from the feed port to the discharge port.

Features: Its advantage lies in its sealing performance, which can effectively prevent dust from spilling, the material from getting damp, or polluting the external environment; it is suitable for conveying materials that have high hygiene requirements, are prone to dust, are toxic and harmful, are prone to moisture, or need to avoid contact with air. In addition, the tubular structure is more compact and may occupy a smaller area.

Price: Compared with the U-trough type, the price of the tubular Twin Screw Conveyor is usually higher, and the cost difference may be 20% to 50% or even higher. This is because the tubular structure has higher requirements for manufacturing process, welding quality and seals, the materials used may be more complex, and it is relatively less convenient than the U-trough type during maintenance, and may require more precise support and installation.

What are the factors affecting the price of Twin Screw Conveyor?

The price of Twin Screw Conveyor is mainly affected by factors such as equipment type, material, size specifications, drive system and degree of customization. The following are its main influencing factors:

Material selection

The material of the parts of the conveyor that contact the material (such as spiral blades and trough bodies) has a huge impact on the price. Carbon steel is a more economical choice and is suitable for materials that are generally non-corrosive and have no special hygiene requirements. Stainless steel (such as SUS304, SUS316L) is suitable for industries with strict requirements for hygiene and corrosion resistance. The cost of stainless steel is much higher than that of carbon steel, among which 316L is more corrosion-resistant than 304 and has a higher price. For extremely abrasive or corrosive materials, wear-resistant alloy steel or wear/corrosion-resistant lining materials may be required, which will significantly increase manufacturing costs.

Dimensions and Specifications

The physical size and designed conveying capacity of the equipment directly affect the amount of material required and the complexity of manufacturing. The longer the conveyor, the more trough, spiral blades and bracket materials are required, and the higher the manufacturing and installation costs. The larger the spiral diameter, the greater the conveying capacity, and the wider trough and stronger motor are required, which increases the price.

Customization and Additional Features

Any customized requirements beyond the standard configuration will increase the price. Special inlet and outlet design, special-shaped feed hoppers or discharge chutes customized according to the site layout. Heating/cooling function, jackets or coils for controlling material temperature. Anti-blocking and anti-bridging design, structural optimization for specific material characteristics.

Twin Screw Conveyor Prices

| Type | Price |

| Small Twin Screw Conveyor | US$ 700-1200 / Piece |

| Medium-sized Twin Screw Conveyor | US$ 500-3000 / Set |

| Large Twin Screw Conveyor | US$ 3000-35000 / Set |

| Shafted Twin Screw Conveyor | US$ 2000-4000 / Set |

| Shaftless twin screw conveyor | US$ 1300-3800 / Piece |

Choosing a suitable Twin Screw Conveyor ultimately requires matching the specific configuration of the equipment with actual needs. When obtaining a quotation, you should provide the equipment supplier with detailed material parameters (such as density, humidity, viscosity, abrasiveness, etc.), clear conveying task indicators (such as hourly conveying volume, total conveying length, whether inclined or vertical conveying is required), and specific requirements for equipment materials, drive modes, control systems, etc.