The difference between powder packaging machine and filling packaging machine

Saturday September-13 2025 17:48:26

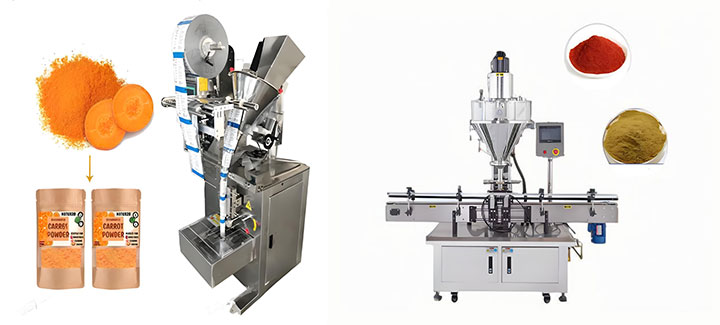

Although both The difference between powder packaging machine and filling packaging machine are used for quantitative packaging of powder materials, the difference between powder packaging machine and filling packaging machine lies in their applicable materials, output, and working principles. Powder packaging machines typically integrate functions such as automatic bag making, metering, filling, sealing, and cutting, and are suitable for small-dose, continuous packaging, such as food, seasonings, and pharmaceuticals. Powder filling packaging machines, on the other hand, are primarily suitable for medium to large-dose prefabricated packaging, such as quantitative filling of powder in containers such as plastic bottles and cans. They are commonly used in industries such as milk powder, chemical powder, and building materials.

In terms of output, powder packaging machines are more suitable for high-efficiency, continuous production lines, while filling packaging machines place greater emphasis on precision and batch stability. In terms of working principle, the former often uses a spiral metering system combined with vibration feeding, while the latter may use a servo-controlled screw feeding system to improve filling accuracy.

The Difference Between Powder Packaging Machine and Filling Packaging Machine

The difference between powder packaging machine and filling packaging machine are explained in terms of material handling, filling mechanism, packaging precision, packaging speed, and capacity range.

Product Handling Method: Powder packaging machines process bulk powder raw materials and typically automatically perform film stretching, bag forming, and sealing. They are suitable for small packages of granular or powdered products. Powder filling packaging machines, on the other hand, focus more on filling powder into prefabricated containers. They require manual or automatic container loading, followed by unloading and sealing. Because filling packaging prioritizes stable container placement, they are often used in conjunction with systems such as bottle unscrambling, capping, and labeling.

Filling Mechanism: Powder packaging machines often use a measuring cup or screw metering method for powder filling, incorporating a vibration device to minimize the impact of air compression on packaging accuracy. Filling packaging machines, on the other hand, often use a high-precision servo motor-driven screw mechanism for quantitative filling, incorporating a weighing system or feedback control to improve metering accuracy.

Precision: Powder filling and packaging machines generally offer superior precision control over powder packaging machines, especially when filling large quantities of powder or for products requiring extremely high precision (such as pharmaceuticals, reagents, and formula powders). Filling machines can achieve an error range of ±0.5%. However, due to the fast pace and continuous packaging process, the accuracy of powder packaging machines is limited by their mechanical structure and packaging speed, typically within ±1-2%.

Packaging Speed: Because powder packaging machines utilize a continuous packaging process, they offer relatively high packaging speeds. A single machine can produce 30 to 60 bags per minute or more, making them suitable for batch production lines. Filling and packaging machines, on the other hand, operate at a relatively slow speed, particularly when involved in bottling, weighing, and capping steps. These machines typically operate at 10 to 30 bottles per minute, prioritizing filling accuracy and stability.

Capacity Range: Powder packaging machines are suitable for small-dose packaging, typically ranging from 10 grams to 500 grams. If the packaging weight exceeds this range, the machine size and energy consumption will increase significantly. The powder filling and packaging machine has a wider capacity adaptability range. Powder materials from tens of grams to several kilograms can be flexibly filled by replacing the screw and adjusting the program.

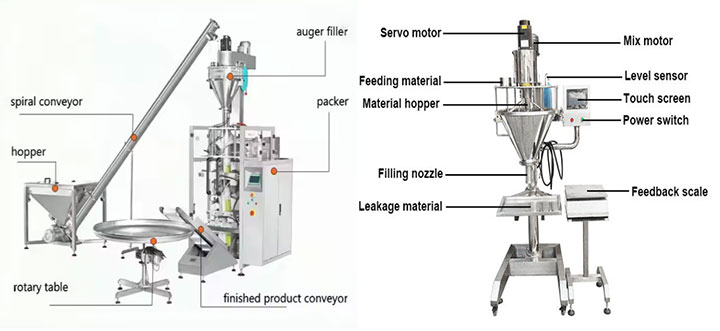

Comparison of Powder Packaging Machine and Filling Packaging Machine Structures

The difference between powder packaging machine and filling packaging machine lies in their structures. The former has a screw conveyor to stir the powder, while the latter has a metering pump to calculate the amount of powder.

powder packaging machine consists of the following main components: a screw conveyor steadily delivers powdered materials to the designated location; a hopper stores raw materials to ensure a stable material supply; a turntable precisely distributes the materials, ensuring an orderly flow into the subsequent process; an auger filler controls the powder quantity to ensure the accuracy of each package; a packaging machine seals the powder within the container; and a finished product conveyor smoothly delivers the finished product for easy processing.

filling packaging machine is driven by a servo motor to ensure stable operation. A feeder conveys the materials to the filling area; a hopper stores raw materials to ensure a continuous supply; a filling nozzle precisely fills the materials to ensure the correct amount; a leak collection device reduces waste; a stirring motor ensures uniform mixing of the materials; a liquid level sensor monitors the volume to prevent overflow; a touch screen facilitates operation; a power switch controls start and stop; and a feedback weighing system ensures filling accuracy.

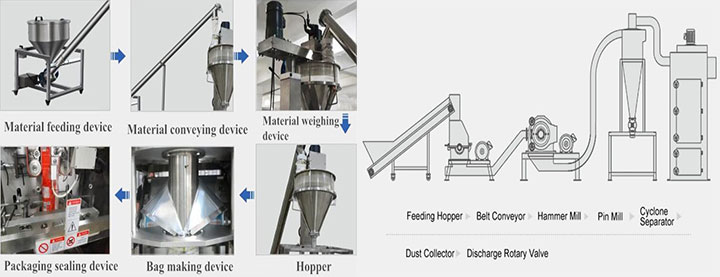

Comparison of Powder Packaging Machine and Filling Packaging Machine Workflows

The difference between powder packaging machine and filling packaging machine is that in the work process, the powder packaging machine focuses on metering and filling the powder, while the filling packaging machine focuses on quantitative filling.The workflow is as follows:

The powder packaging machine workflow includes six steps: material feeding, conveying, weighing, temporary storage, bag making, and sealing. Material is first fed into the feeder, conveyed via a screw conveyor, and then fed into the weighing system. After weighing, it is temporarily stored in the hopper. The bag making unit then forms the packaging film into bags, and the sealing unit completes the automatic packaging.

The filling packaging machine workflow involves material entering through the feed hopper, being conveyed by a belt conveyor to the crushing equipment (hammer mill, pin mill), then passing through a cyclone separator for solid-gas separation. Dust is collected by a dust collector, and the finished product is discharged through a rotary discharge valve.

The difference between powder packaging machine and filling packaging machine give each product its own advantages and applicable scenarios. The decision must be made based on product characteristics, packaging specifications, and production requirements. If the product is a small amount of powder for a single use, such as daily seasonings, health powders, and granules, and a high speed is required, a powder packaging machine is the first choice. If the product is infant formula, building material additives, veterinary drugs, and other products that require quantitative canning and require high precision and product stability, a powder filling and packaging machine is more suitable. The former has a compact structure and high speed, suitable for small packages and continuous production lines, while the latter has high precision, a wide range of capacities, and is suitable for high-quality packaging of bottles and cans.