Powder Packaging Machine Price

Friday November-28 2025 11:18:23

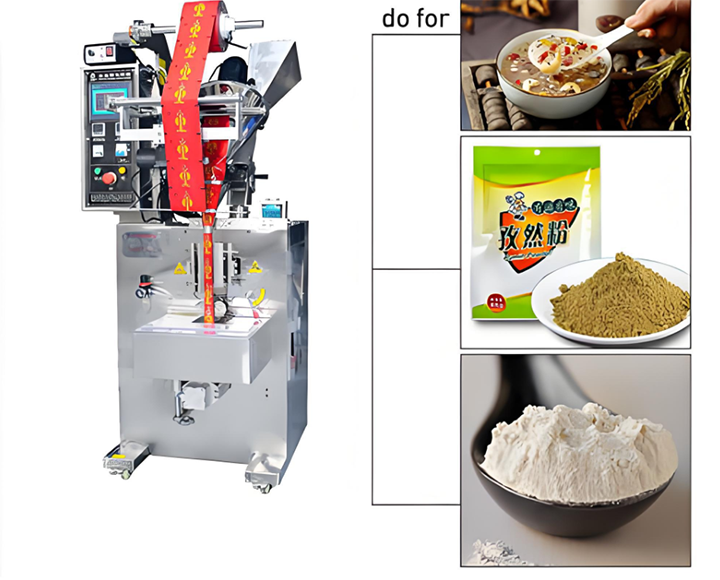

Powder Packaging Machine Price ranges from USD 1,000–9,000.Powder Packaging Machine key functions include automatic metering and filling, heat or seam sealing, coding and inkjet printing.The machine supports packaging ranging from 1g to 500g, with packaging formats including upright bags, pillow bags, and small packaged packaging. For powders that are easily hygroscopic or easily oxidized, the shelf life can be extended by vacuuming or filling with nitrogen.Different powder types require corresponding feeding systems, such as screw, vibratory, and vacuum feeders.

Powder Packaging Machine include models such as MC5000D, WM-FG06, and ZONESUN 2-200g powder filling machine. Different models result in different price options, ranging from approximately $2,000 to $9,000. The production capacity of powder packaging machines varies from small models that can produce 50 bags per hour to high-speed models that can produce more than 5,000 bags per hour.They are suitable for a variety of materials, including milk powder, coffee powder, chemical powder, and pharmaceutical powder.

What are the advantages of Powder Packaging Machine Price?

Economical machines can handle basic packaging processes such as metering, filling, bag making, and sealing, making them suitable for small-batch production, companies with low precision and speed requirements, and limited budgets. Automated models can automatically load bags, fill, weigh, and seal, achieving packaging accuracy of ≤±0.1-0.2%. Leak-proof sealing technology reduces powder leakage, and equipped with an intelligent alarm system for real-time production monitoring and timely detection of potential problems, resulting in reduced overall costs. They can be integrated with elevators, vacuum feeders, checkweighers, and other machines to form automated systems, saving labor and improving production efficiency.

Powder Packaging Machine Parameters

| VFFS -320 | VFFS-420 | VFFS-520 | VFFS-720 | |

|---|---|---|---|---|

| Packing Speed | 5-70bags/min | 5-60bags/min | 5-50bags/min | 5-40bags/min |

| Bag Length | 50-200mm | 80-300mm | 100-400mm | 100-450mm |

| Bag Width | 50-150mm | 50-200mm | 100-250mm | 100-350mm |

| Film Roll Diameter | Max.320mm | Max.320mm | Max.320mm | Max.320mm |

| Filling Range | 50-800ml | 150-1200ml | 200-2000ml | 250-4000ml |

| Film Width | Max. 320mm | Max. 420mm | Max. 520mm | Max. 720mm |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Air Consumption | 0.3m3/min 0.65MPa | 0.3m3/min 0.65MPa | 0.4m3/min 0.65MPa | 0.4m3/min 0.65MPa |

| Voltage | AC220V 50Hz | AC220V 50Hz | AC220V 50Hz | AC220V 50Hz |

| Power | 2.0kw | 2.2kw | 4kw | 4.5kw |

| Machine Dimensions | 117*82*129cm | 132*95*136cm | 149*108*149cm | 172*126*182cm |

| Machine Weight | 350kg | 550kg | 750kg | 850kg |

What are the types of Powder Packaging Machine Price?

Powder Packaging Machine Price is different between different types. There are models suitable for small sachet packaging, high-speed production, dust-proof systems, and specialized materials. In short, you can choose the machine at the right price based on your needs.

There are two common types of powder packaging machines,bag-making type and pre-made bag type. Bag-making type powder packaging machine priced between $1,500 and $6,000, are fully functional and can automatically complete the entire process from roll film making to metering, filling, and sealing, producing 30 to 60 bags per minute. They are suitable for packaging various powders weighing from 1 to 100 grams, such as coffee powder and pharmaceutical powder. Pre-made bag packaging machines, priced between $9,000 and $15,000, use pre-made stand-up pouches and zipper bags, achieving a production rate of 20 to 50 bags per minute through bag picking, opening, metering, and sealing mechanisms. Their advantage lies in their aesthetically pleasing packaging and flexible design changes.

For higher production capacity or specific applications, fully automatic models are the mainstream choice. Fully automatic powder packaging machine priced between $7,000 and $10,000, integrate automatic feeding and PLC control systems, achieving speeds of 50 to 120 bags per minute, suitable for rapid mass production. In addition, for industries with fine powder or strict dust control requirements, specialized snuff packaging machines are equipped with a fast dust removal and sealing system, which can process 40 to 80 bags per minute and cost between $2,000 and $9,000.

How to make purchase based on Powder Packaging Machine Price?

Powder packaging machines not only perform filling and sealing, but also allow for interchangeable feeding devices tailored to powder characteristics, enabling the packaging of a wider range of materials, such as spices, dry spices, coffee, detergent powder, flour, and soy milk powder. When purchasing a powder packaging machine, it's important to determine your needs and then consult the supplier about the powder packaging machine price.For businesses or individuals with small production volumes and limited packaging options, small or semi-automatic powder packaging machines are an economical choice. For medium to large-sized enterprises requiring high efficiency, high automation, and support for multiple powder and packaging formats, mid- to high-end fully automatic equipment is recommended, as it improves production efficiency and product quality consistency.

Powder Packaging Machine Supplier

Consider machinerise, which has over 15 years of experience in equipment manufacturing and can quickly provide a manufacturing solution after understanding your requirements. Our equipment can package various bag types, including three-side seal bags, four-side seal bags, back seal bags, and stand-up pouches. Bag widths range from 50mm to 200mm, and heights from 80mm to 300mm, suitable for small bags from 50g-500g to large packaging bags over 5kg. All our equipment is CE certified. As a direct manufacturer, we offer highly competitive powder packaging machine prices.