Fully automatic batching packaging machine price

Friday July-04 2025 15:06:42

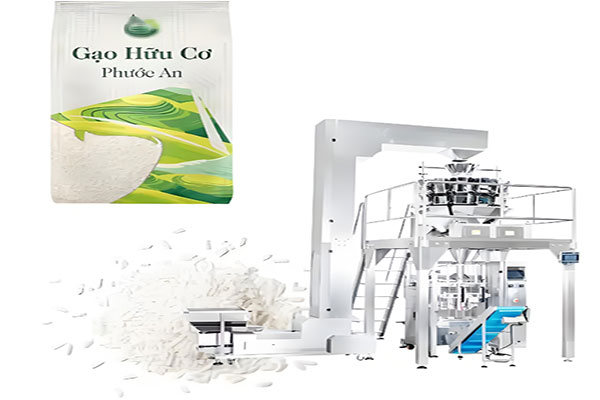

The price of Fully automatic batching packaging machine varies depending on factors such as material type and function. The core functions of the equipment cover the automatic weighing, mixing, conveying and packaging of materials such as granules, powders and liquids. It supports various forms such as bagging, bottling and canning, and is compatible with plastic, paper bags, aluminum foil and other packaging materials. On the technical level, the equipment uses high-precision sensors and PLC control systems, combined with multi-head combination scales or screw metering technology to ensure that the single batching error is controlled within ±0.1%. In addition, the modular design allows users to select dust prevention, automatic cleaning, remote monitoring and other functions according to their needs to adapt to different production scenarios. In terms of output, small and medium-sized equipment (such as vertical packaging machines) can reach a speed of 60-75 bags/minute, and large production lines (such as robot palletizing integrated systems) can exceed 100,000 bags per day. The starting price of basic equipment is about US$5,000, and the customized production line is about US$20,000.

Fully automatic batching packaging machine workflow

The operation process of the fully automatic batching packaging machine is divided into four stages: raw material delivery, batching, automatic packaging, and output:

Raw material delivery: The material is transferred from the storage bin to the metering unit through a Z-type feeder or a vacuum conveying system. The contact part is made of food-grade PP or 304 stainless steel to ensure hygiene and safety.

Precise batching: The multi-head combination scale dynamically distributes the material according to the preset parameters. For example, a 10-head combination scale can handle 10 different materials at the same time, and achieve micron-level mixing through high-speed vibration.

Automatic packaging: The measured material enters the vertical packaging machine to complete bag making, filling, sealing and other actions. Some equipment integrates a manipulator to realize automatic bag taking, bag opening and bagging of pre-made bags, reducing manual intervention.

Finished product output: The packaged products are sent to the palletizing area via a conveyor belt, and the robot completes automatic stacking and winding, and finally forms a standardized pallet.

Fully automatic batching packaging machine core advantages

Fully automatic batching packaging machine has many advantages. It not only has high-precision automatic weighing and batching functions to ensure product consistency and reduce waste, but also greatly saves labor costs through full process automation. Its closed conveying and packaging system meets food-grade or pharmaceutical-grade hygiene standards to ensure production safety. At the same time, the equipment supports high-speed mass production, significantly improving production capacity; it can be connected to the ERP system to realize automatic data recording and remote monitoring; and has good adaptability, can flexibly adjust the formula, suitable for a variety of materials and packaging forms, to meet diversified production needs, and is easy to maintain, with a friendly operation interface, improving the user experience.

Fully automatic batching packaging machine price

The fully automatic batch packaging machine is widely used in food, medicine, chemical, electronics and other industries due to its efficient and accurate packaging capabilities. Different application scenarios have different requirements for equipment performance and packaging speed, and the price also varies.

In the food industry, such as granular candy, seasonings and other packaging, the machine packaging speed is generally 30-100 bags/minute, which is suitable for small and medium-sized production needs, and the price ranges from US$7,000 to US$28,000. The equipment has anti-stick and moisture-proof functions, and users can flexibly choose according to the output.

The pharmaceutical industry has extremely high requirements for hygiene, and the equipment is mostly made of stainless steel. The packaging speed is usually 20-60 bags/minute, which is suitable for high-standard medium-volume production, and the price is about US$14,000 to US$42,000. Accurate metering and traceability are its main features.

The chemical industry packs powder or granules, and the equipment packaging speed is mostly 25-80 bags/minute, which is suitable for batch production, and the price range is US$11,000 to US$35,000. The equipment is corrosion-resistant and multi-bag compatible.

For high-precision packaging scenarios such as electronic components, the packaging speed is lower, generally 15-50 bags/minute, but the accuracy is extremely high, and the price is usually above US$21,000.

Fully automatic batching packaging machine price varies depending on the type of material and function selection. The equipment is widely used in food processing, chemical ingredients and agricultural material packaging. It plays a key role in improving production efficiency, ensuring product quality and reducing operating costs. The equipment can achieve accurate proportioning and high-speed packaging of multiple materials, ensuring efficient and stable production process. For enterprises that require stable output and multi-material proportioning, the fully automatic batching and packaging machine not only improves the level of automation, but also significantly reduces labor and errors, and improves product consistency.