Cattle for feed pellet machine

Specialized equipment for processing raw materials such as corn stalks, soybean meal, and forage into pelletized feed. It is divided into household type (daily output ≤ 500 kg) and large-scale production type (daily output ≥ 1 ton) according to production capacity

Pellet diameter: 2mm-12mm (commonly used 6mm, 8mm)

Suitable raw material moisture: 10%-15%

Output: 300kg/h-5t/h (depending on the model)

Power: 7.5kW-75kW

What is a cattle for feed pellet machine

Cattle for feed pellet machine is a mechanical equipment that presses powdery or fibrous feed raw materials into pelletized cattle feed. It is suitable for a variety of raw materials such as corn meal, soybean meal, wheat bran, hay meal, straw, and distiller's grains. Cattle feed has the characteristics of complex nutrients, high crude fiber content, easy moisture absorption and agglomeration, etc. Pellet processing can significantly increase feed density, improve palatability and storage performance, prevent cattle from being picky eaters, and ensure balanced nutritional intake.

The pellet feed pressed by the cattle for feed pellet machine has a dense structure, which is convenient for transportation and long-term storage, and at the same time improves the chewing efficiency and digestion and absorption rate of ruminants. This equipment is widely used in small and medium-sized farms and large feed processing plants. It is an important tool for improving feed utilization and management efficiency in modern cattle breeding production.

What are the raw materials of cattle feed pellets?

It can be applied to a variety of cattle feed formulas, such as: corn meal, soybean meal, wheat bran and other concentrates; hay meal, alfalfa meal; corn stalks, sugarcane bagasse, distiller's grains; microbial fermentation feed, forage powder, etc.

Pellet diameter: common 6mm, 8mm, 10mm, suitable for cattle at different growth stages

Pellet density: pressed full, not loose, conducive to storage and transportation

What are the types of cattle feed pellets

Ring die feed pellet machine: mainly composed of feeding system, mixing system, pelleting system, transmission system, etc. During operation, the material is squeezed out of the die hole of the ring die under the extrusion of the roller and the ring die to form granular feed. Its advantages are high production efficiency, good pellet quality, strong stability, and suitable for large-scale feed processing and production.

Flat die feed pellet machine: Based on the circular motion of the machine, the motor is used as the power to drive the gear to the main shaft and the flat die. Under the action of friction, the pressure wheel rotates, and a high friction temperature is generated between the pressure roller and the template, so that the powdered material is gelatinized at high temperature and the protein is coagulated and denatured, and extruded from the die hole under the extrusion of the pressure wheel. It has a large pressure and has a good molding effect on coarse fiber materials such as sawdust and straw. It is suitable for small and medium-sized farms and individual breeders.

Flat die feed pellet machine: The material is squeezed into granules through two relatively rotating pressure rollers. It has a simple structure and is easy to operate, but the production efficiency is relatively low. It is suitable for small feed processing or experimental research.

Working principle of cattle for feed pellet machine

The cattle for feed pellet machine sends the material into the pressing chamber through a screw conveyor. Under the action of pressure and temperature, the pressure roller presses the feed into the die hole and extrudes it to form dense and regular particles. The particle length can be adjusted by the cutter.

① Raw material pretreatment: After the powdered material is magnetically separated and iron is removed, it is mixed with water vapor, molasses, etc. to make the moisture content reach 15%-19%.

② Pressing and molding: The material enters the pressing chamber and is squeezed by the roller and the ring die (gap 0.1-0.3mm) to form long strips of particles through the die hole.

③ Cutting and discharging: The cutter adjusts the position to control the particle length (usually 3-10mm), and finally produces cylindrical particles.

What are the advantages of cattle for feed pellet machines?

Granulating raw materials and moisture, strong adaptability: the overall structure is relatively simple, the footprint is small, and the installation and operation are relatively convenient. It can adapt to a variety of different materials, such as corn stalks, sawdust, grass powder, etc., and can also be used for low-temperature granulation of biological fertilizers, organic fertilizers, compound fertilizers, etc. Powdered feed and grass powder do not need or only need a little liquid to be added for granulation. The moisture content of pellet feed is basically the moisture content of the material before granulation, which is more conducive to storage.

Dry material processing and convenient storage: powdered feed and grass powder do not need or only need a little liquid to be added for granulation. The moisture content of pelleted feed is basically the moisture content of the material before granulation, which is more conducive to storage and reduces problems such as mold and deterioration caused by moisture.

Multiple aperture molds are available: generally, there are multiple aperture molds with a diameter of 1.5-20mm. According to different materials and breeding needs, the appropriate aperture mold can be selected to adapt to the granulation of different materials to achieve the best effect.

Improve feed quality: The produced feed pellets have high hardness, smooth surface, and internal maturation, which can improve the digestion and absorption capacity of nutrients. The particle formation process can denature the pancreatic enzyme resistance factor in grains and beans, reduce the adverse effects on digestion, and kill various parasite eggs and other pathogenic microorganisms, reducing various worms and digestive system diseases.

Technical parameters of cattle for feed pellet machine

Flat-type cattle for feed pellet machine model parameter table (suitable for small and medium-sized farmers)

|

Model |

main engine power (kW) |

output (kg/h) |

particle diameter (mm) |

die diameter (mm) |

outline dimensions (mm) |

weight (kg) |

|

120 type |

3.0 |

60-100 |

2.5-8 |

120 |

750×320×720 |

100 |

|

150 type |

4.0 |

90-150 |

2.5-8 |

150 |

750×350×75 0 |

120 |

|

200 type |

7.5 |

200-300 |

2.5-8 |

200 |

1000×430×950 |

210 |

|

250 type |

11.0 |

300-500 |

2.5-8 |

250 |

1150×470×970 |

270 |

|

300 type |

15.0 |

500-800 |

2.5-10 |

300 |

1270×520×1020 |

350 |

Annular mode cattle for feed pellet machine model parameter table (suitable for large feed mills or breeding enterprises)

|

Model |

Host power (kW) |

Output (kg/h) |

Particle diameter (mm) |

Number of mold holes |

Dimensions (mm) |

Weight (kg) |

|

320 type |

37 |

1000-1500 |

6-10 |

Porous |

1850×800×1600 |

1200 |

|

350 type |

55 |

1500-2500 |

6-10 |

Porous |

2100×950×1700 |

1800 |

|

420 type |

75 |

3000-4000 |

6-10 |

Porous |

2600×1 100×1900 |

2500 |

|

508 type |

90 |

4000-6000 |

6-12 |

porous |

2800×1300×2000 |

3000 |

|

600 type |

110 |

5000-8000 |

6-12 |

porous |

3100×1400×2200 |

4000 |

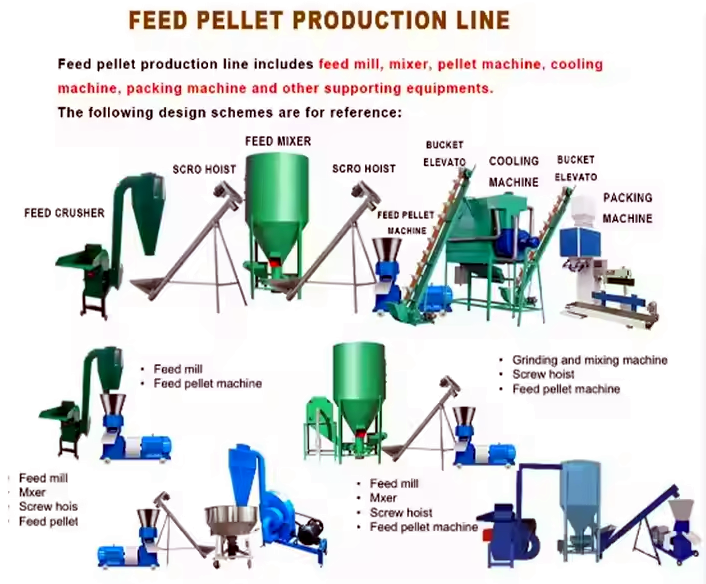

Feed pellet production line

What can the cattle for feed pellet machine be used for

Cattle feed pellet machine is mainly used to process various powdered or crude fiber cattle feed raw materials into regular pellet feed, which is widely used in cattle production.

In fattening cattle farms, pellet feed can be added with corn flour, soybean meal, wheat bran, trace elements, etc. through precise proportions to increase daily weight gain and reduce waste. In dairy farms, pellet machines can press nutrient pellets containing alfalfa meal, cottonseed hulls, minerals and other ingredients to promote the increase of milk volume and dairy product quality. In the free-range farming model of farmer households, pellet machines can mix and compress corn stalks, hay meal and grain by-products to facilitate daily feeding and long-term storage.