Food conveyor belt

The price of food conveyor belt varies depending on its conveying length, bandwidth, drive mode, and degree of automation, usually ranging from US$100 to US$7,500.

Material: stainless steel/carbon steel/plastic

Voltage: 220/380V

Power: 2.2 kW

Speed: 20 m/min/adjustable

Belt material: PVC/ PU rubber/ PVC /PP

Size (l×w×h): customized

What is Food conveyor belt?

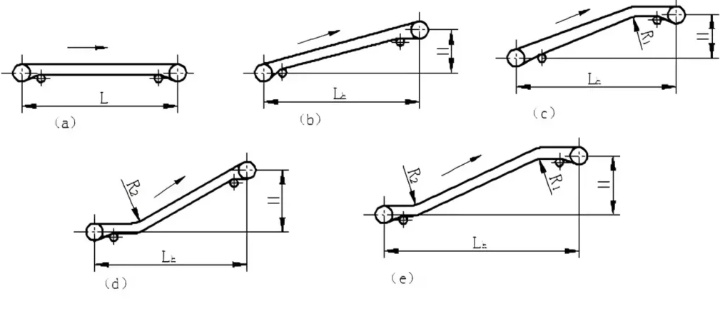

Food conveyor belt are mainly used in food processing, production and packaging. This type of conveyor can be divided into center-driven and trough types according to the drive mode and conveyor belt shape. At the same time, it can be divided into horizontal, inclined and Z-type configurations according to different conveying paths to adapt to different sites and process requirements. In terms of material handling capacity, food conveyor belts can handle hundreds of kilograms to tons of materials per hour. This equipment is an indispensable part of the food production line, supporting the smooth transfer of materials between different processing links.

What are the types of food conveyor belts?

Food conveyor belts can be divided into various types according to their structure and conveying paths. These classifications include horizontal type, large-angle type (including skirts and partitions) based on conveying angle and material holding method, and center-driven type and trough type based on drive mode and conveyor belt shape to adapt to the diverse material conveying needs in food processing.

Horizontal belt conveyor

The conveyor belt of this type of conveyor runs straight and parallel to the ground. They are common types of belt conveyors with relatively simple structures. Mainly used for plane transfer of food products at the same height. It is suitable for all kinds of bulk, granular or packaged food.

High-angle belt conveyor (including skirts and partitions)

This type of conveyor can lift food materials from low to high, and the conveyor belt is inclined at a large angle to the horizontal plane. In order to prevent the material from sliding down or overflowing from both sides during the inclined conveying process, a special structure is usually added to the conveyor belt, such as wavy or upright skirts bonded on both sides of the conveyor belt to form a trough-shaped space, which effectively prevents the material from spilling from the edge of the conveyor belt. Horizontal partitions are fixed at equal intervals on the surface of the conveyor belt. These partitions cooperate with the skirts to separate the surface of the conveyor belt into independent "material grids", ensuring that the material is stably carried and pushed up on the steep slope and is not easy to roll back.

Z-type belt conveyor

The Z-type conveyor combines the characteristics of horizontal and inclined conveying, and its conveying path is in the shape of "Z" or "S". It usually includes a horizontal feeding section, an inclined lifting section, and a horizontal discharging section. Similar to high-angle conveyors, in order to adapt to the conveying of inclined sections, the conveyor belt of Z-type conveyors is usually equipped with skirts and cross-partitions. It is suitable for working conditions where materials need to be fed from a low level, lifted by a large height difference, and then discharged at a high level.

Intermediate drive belt conveyor

The drive device (motor and reducer) of this type of conveyor is not set at the head or tail of the conveyor, but is located somewhere in the middle of the conveyor. This design allows the conveyor to load or unload materials more flexibly at both ends, or provide power in areas with limited space. Intermediate drive conveyors can usually achieve bidirectional conveying, that is, materials can move in both directions. It is suitable for food production lines that require flexible layout, bidirectional conveying functions or are limited in conventional drive positions.

Trough/V-type belt conveyor

Trough conveyors lift the two sides of the flat conveyor belt to form a V-shaped or U-shaped trough. This is usually achieved through special roller sets (such as trough rollers) so that the conveyor belt is grooved in the part carrying the material. It is mainly used for conveying bulk, granular or powdered food materials with good fluidity. The trough design can effectively increase the cross-sectional area of the conveyor belt, thereby increasing the conveying capacity and preventing the material from rolling or spilling from both sides during the conveying process, ensuring the concentrated and stable conveying of the material.

What are the advantages of food conveyor belts?

Food conveyor belts have many advantages in food processing and production, such as reducing cross-contamination, continuous and stable transportation, adapting to diversified products, durability and easy maintenance, making them an indispensable equipment in the industry:

Safety and hygiene: This is the key advantage of food conveyor belts. They are usually made of food-grade materials such as PU or PVC, which are non-toxic, odorless and not easy to react chemically with food. The conveyor belt surface is smooth and non-porous, and it is not easy to retain food debris or breed bacteria, supporting high standards of cleaning and disinfection. Many designs also allow quick disassembly for thorough cleaning.

Reduce cross-contamination: Compared with manual operation, food conveyor belts reduce direct contact between food and human hands or other unsterilized surfaces, thereby reducing the risk of microbial and foreign body contamination. The closed or easy-to-clean design further reduces the impact of dust and debris in the environment on food.

Continuous and stable transportation: Food conveyor belts can provide a continuous and smooth material flow to transfer food products from one processing link to the next, avoiding the efficiency loss caused by intermittent operation. This continuity helps optimize the production process and improve the operation of the overall production line.

Adapt to diverse products: Whether it is bulk granules, block food, or packaged finished products, the food conveyor belt can effectively convey them. By choosing the appropriate conveyor belt surface texture (such as smooth, non-slip), baffles or skirts, and adjusting the conveying speed, it can adapt to different types and forms of food products.

Durable and easy to maintain: The materials used in food conveyor belts usually have good wear resistance, oil resistance, water resistance and corrosion resistance, and can adapt to the harsh conditions commonly found in food processing environments, such as high temperature, low temperature or humid environments. The sturdy structure and easy-to-clean characteristics also make the daily maintenance of the equipment relatively convenient, which helps to extend the service life of the equipment and reduce downtime.

Parameters of food conveyor belt

|

Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 5-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

| 30 | 55-75 | 75-185 | |||

What is the principle of food conveyor belt?

The working principle of food conveyor belt is based on friction drive, which continuously operates by pulling the conveyor belt to achieve smooth and continuous transfer of food materials. Its core design and material selection strictly follow food safety and hygiene standards.

Power transmission: The drive device of the conveyor (usually composed of an electric motor and a reducer) drives the drive roller at one end of the conveyor to rotate.

Driving the conveyor belt: Friction is generated between the driving roller and the endless conveyor belt. This friction causes the conveyor belt to be driven and start a continuous circular motion, bypassing the redirecting roller at the other end to form a closed loop.

Material carrying and movement: Food materials are placed on the surface of the running conveyor belt and will move forward with the conveyor belt. The smooth running characteristics of the conveyor belt ensure that the materials are not piled up, spilled or damaged during the conveying process.

Support and guidance: Under the conveyor belt, rollers or flat support plates provide support to prevent the conveyor belt from sagging and ensure that it remains straight and stable throughout the entire running path.

Material unloading: When the food material reaches the discharge end with the conveyor belt, the conveyor belt bypasses the roller or a specific unloading point, and the material slides off the conveyor belt or is thrown off due to gravity or inertia, and enters the subsequent process or collection container.

Tensioning and deviation correction: The tensioning device is responsible for adjusting the tightness of the conveyor belt to prevent slipping. The deviation correction device (such as the automatic deviation correction roller) ensures that the conveyor belt always stays on the correct track during operation to prevent deviation.

In addition to the above basic principles, the food conveyor belt also incorporates the core requirements of the food industry for hygiene and safety, such as sanitary design. All parts that come into contact with food (such as conveyor belts and racks) are made of food-grade materials and designed to be easy to clean to avoid dead corners and dirt, ensuring that the material is not contaminated during transportation. Cleaning and maintenance, the materials of the conveyor belts and racks can withstand common food-grade detergents and disinfectants, and many designs also support quick disassembly for easy and thorough cleaning to maintain strict hygiene standards. This design enables the food conveyor belt to achieve continuous and automated production processes while ensuring food safety and hygiene.

What are the applications of food conveyor belt?

Food conveyor belt is mainly used in various production and processing links that require safe, hygienic and continuous transfer of bulk or packaged food materials. Its core uses are reflected in:

Material transfer and process connection: between different stations of the production line, it can smoothly transport food raw materials, semi-finished products or finished products from one processing unit to the next unit to realize automated and continuous production processes. For example, convey washed fruits and vegetables to the cutting machine, or convey baked products to the packaging area.

Sorting and grading: Combined with visual recognition systems or other sensors, food conveyor belts can be used to automatically sort food, remove unqualified products or grade them according to characteristics such as size and color to improve product quality and standardization.

Cooling and heating: By using a conveyor belt made of specific temperature-resistant materials, it can provide cooling (such as chocolate solidification, baking product cooling) or heating (such as preheating, drying) environment for food materials during transportation, thereby integrating process steps.

Weighing and metering: The conveyor can be combined with an online weighing system to accurately weigh and meter materials during material movement to ensure the accuracy of product packaging or control the proportion of ingredients.

Pre-packaging processing: Before the food enters the final packaging link, the belt conveyor is often used to sort, arrange or convey the material to the feed port of the automatic packaging machine to ensure the smooth packaging process.

What are the cases of Food conveyor belt?

Food conveyor belt has a wide range of application scenarios in all aspects of the food industry due to its compliance with hygiene standards and stable operation. These applications cover multiple stages from raw material processing to final product packaging. In the early stages of food production, Food conveyor belt is often used for the transportation of bulk raw materials. Such as agricultural product primary selection and cleaning, meat and aquatic product processing, grain and bean transportation, etc. Between the various process steps of food processing, Food conveyor belt plays a key role in connection to ensure the continuity of the production process. For example, after the cooling of baked products, baked foods such as bread and biscuits are taken out of the oven, they are naturally cooled or forced cooled by high-temperature resistant or cooling conveyors. Fried food conveying: fried potato chips, puffed food, etc. are sent to the seasoning or packaging stage through conveyors. In candy and chocolate production, conveyors are used for continuous product delivery in candy molding, cooling, coating and other stages. Before the product enters the final packaging stage, the conveyor plays an important role, such as product sorting and arranging, sorting and aligning the scattered products during the conveying process, so as to facilitate the subsequent automatic boxing and bagging. Conveyor to the packaging machine, accurately convey the processed food products to the feed port of the vertical packaging machine, bag-feeding packaging machine, and cartoning machine. Finished product output and palletizing: the packaged products are conveyed to the palletizing area or shipping area through conveyors. In addition to conventional conveying, the Food Conveyor Belt can also adapt to some special needs, such as cold chain conveying. In cold storage or low-temperature processing environments, low-temperature resistant belts and components are used to ensure the continuous conveying of frozen or refrigerated foods. In clean production areas with extremely high requirements for environmental hygiene, food-grade conveyors with easy-to-clean and no-dead-angle designs are used. Cleaning conveying: some conveyors can be designed to spray or drain during the conveying process, with integrated cleaning functions. In general, food conveyor belt is the basic equipment for the food industry to achieve automation, standardized production, and ensure food safety and hygiene. It is widely used in all links from primary processing to final packaging.

The advantage of food conveyor belt is that it can meet strict hygiene requirements. By selecting food-grade materials and easy-to-clean design, it helps to maintain the cleanliness of the production process. At the same time, this type of conveyor can provide continuous and smooth transfer of materials, supporting the smooth connection of production processes. Its various types and configurations enable it to adapt to different material forms and site restrictions, for example, to cope with the needs of horizontal movement, height difference lifting, or material transfer in confined areas.