Vertical Form Fill Seal Packing Machines Suppliers

Tuesday July-08 2025 18:15:34

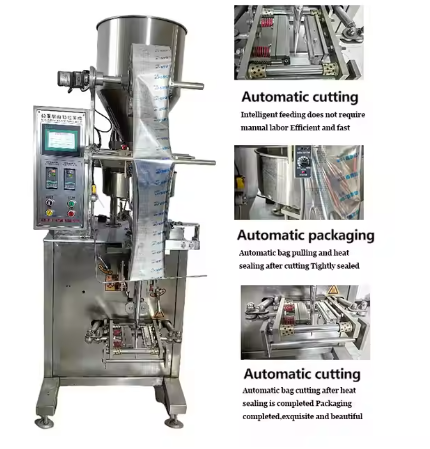

The production speed of Vertical Form Fill Seal Packing Machines generally ranges from dozens to hundreds of bags per minute, and high-end equipment can even reach more than 500 bags per minute. Its main functions include automatic bag making, metering, filling, sealing and cutting, which can achieve fully automated production, greatly improve packaging efficiency and reduce labor costs. Vertical Form Fill Seal Packing Machines Suppliers can be selected based on actual production capacity or material requirements.

From the working principle, the Vertical Form Fill Seal Packing Machines first provides packaging film from the roll film supply device, and the packaging film is formed into a cylinder by the forming device, and then enters the filling area. The equipment automatically fills the material into the bag according to the set metering method (such as weighing, volume, counting, etc.), and then completes the sealing and cutting through the heat sealing device to form a separate packaging bag. The whole process is coherent and fast.

The core function of Vertical Form Fill Seal Packing Machines

The core function of the VFFS packaging machine is to realize automatic metering and convenient packaging of materials. Specifically, the core functions mainly include the following aspects:

Automatic bagging function: The flat packaging film is made into packaging bags of the required shape through mechanical or pneumatic devices to meet the needs of different specifications and sizes.

Precise metering and filling: Combined with a variety of metering systems (such as weighing, volumetric, spiral, etc.), the weight or volume of each bag of materials is accurately consistent to improve the packaging quality.

Quick sealing: Heat sealing technology is used to ensure the sealing of the packaging bag, prevent the material from getting wet or leaking, and extend the shelf life of the product.

Intelligent control: Through PLC and touch screen operation, automatic parameter adjustment, fault alarm and real-time monitoring of production data are realized to improve the intelligence level of the equipment.

Multi-function integration: Some high-end Vertical Form Fill Seal Packing Machines also integrate additional functions such as printing date, coding, inflation, and dust prevention to meet the special needs of different customers.

Selection of Vertical Form Fill Seal Packing Machines Suppliers

Choosing the right Vertical Form Fill Seal Packing Machines Suppliers is the key to ensuring stable and convenient production. Supplier selection should consider technical strength, product quality and after-sales service system. Only by comprehensively considering the above factors and combining the actual production needs and budget can we find the most suitable VFFS packaging machine supplier. Our factory has a wide range of products, which can be customized according to different materials and production capacity requirements. At the same time, we provide free trial machine service with materials and professional selection guidance to help customers achieve convenient and intelligent packaging production. Combine actual needs and budget to choose the most suitable supplier.

Applicable materials of Vertical Form Fill Seal Packing Machines

Vertical Form Fill Seal Packing Machines are applicable to a wide range of materials due to their flexible packaging and various metering methods. Common applicable materials include: granular materials such as rice, beans, nuts, candies, dried fruits, seeds, etc., which are ideal for packaging by weighing or volume measurement; powdered materials such as flour, milk powder, coffee powder, seasoning, chemical powder, etc., which require special powder filling devices to ensure that there is no dust leakage during the packaging process; liquid and paste materials such as sauces, oils, beverages, dairy products, etc., some high-end Vertical Form Fill Seal Packing Machines have liquid filling functions and good sealing performance; sheet and strip materials such as tablets, dried vegetables, instant noodles, etc., which can be automatically metered through special feeding devices; and other special materials such as frozen foods, medical supplies, hardware, etc., which require different packaging films and process adjustments.

As an important equipment for modern automated packaging production lines, Vertical Form Fill Seal Packing Machines have suppliers all over the world, especially in China, the United States, Germany and other places. Its core functions include automatic bagging, precise metering, efficient sealing and intelligent control to ensure high production and high-quality packaging results. The selection of suppliers should take into account technical strength, production capacity, after-sales service and customization capabilities to meet the production needs of enterprises. VFFS packaging machines have a wide range of applications and can handle a variety of material types such as granules, powders, liquids, flakes, etc. They are widely used in food, medicine, chemicals and other industries. Our factory has the characteristics of rich product types, customization, and trial operation with materials, and is committed to the design and manufacture of packaging machines.