Vertical bucket elevator

The price of a vertical bucket elevator varies significantly depending on its type, handling capacity, lifting height, material. Its price ranges from $200 to $5,000.

Power: 750 watts

Dimensions: 2100x730x2350mm/customizable

Width or diameter: 500mm/customizable

Voltage: 220/380V

Bucket volume: 0.15

Lifting height: 1.9 meters

What is Vertical bucket elevator?

vertical bucket elevator is an important bulk material conveying equipment. This type of equipment usually consists of a series of hoppers fixed on a continuous traction member (such as a belt or chain), and a drive system is used to achieve continuous and uninterrupted cyclic lifting. Depending on the application requirements and material characteristics, the construction materials of the Vertical bucket elevator are diverse. For example, carbon steel is common in occasions where general industrial materials are handled, while stainless steel is widely used in areas with high requirements for hygiene or corrosion protection. Its design can adapt to material handling tasks of different sizes, from small conveying of several tons per hour to large conveying of hundreds of tons per hour. In actual applications, the lifting height can range from several meters to tens of meters, providing a practical solution for material transfer in various production environments.

What are the advantages of Vertical bucket elevator?

Vertical bucket elevators play an important role in many industrial applications. They have many significant advantages that make them an ideal choice for vertical conveying of bulk materials. The advantages of vertical bucket elevators are mainly as follows:

Conveying capacity: Bucket elevators can handle large amounts of materials in a fast and continuous manner to achieve material conveying. They can automatically complete the vertical conveying of materials, greatly improving production efficiency.

Space saving: Vertical bucket elevators use vertical conveying, occupy a small area, and can effectively utilize vertical space. This is especially beneficial for facilities with limited plant space, and existing space can be used for equipment layout.

Reduced material loss and contamination: Bucket elevators usually operate in a closed system, which reduces the risk of material spillage, dust flying, and cross contamination. This not only helps to keep the working environment clean and safe, but also effectively protects the quality of materials.

Wide range of applications: Bucket elevators are highly versatile and can convey various types of bulk materials, including grains, powders, granules, block materials, and even some abrasive or corrosive materials. By choosing different types and materials of buckets and belts, different material characteristics and conveying requirements can be adapted.

Gentle handling of materials: For fragile or carefully handled materials, bucket elevators can provide a relatively gentle conveying method to reduce material breakage and degradation during the conveying process.

Durability and low maintenance: Vertical bucket elevators are typically built with durable materials and components that can withstand the rigors of continuous operation. They are typically designed with fewer wearing parts, which reduces maintenance requirements and operating costs, providing a good return on investment.

How does a vertical bucket elevator work?

A vertical bucket elevator is a machine that lifts bulk materials from a low location to a high location using a series of hoppers. First, the material enters the elevator through a feed port at or slightly above the bottom of the elevator and is directed to the hopper area at the bottom of the elevator. Next comes the loading process: the hopper, which is fixed to a continuous traction member (such as a belt or chain), is filled with material as it passes through the material pile. There are two ways to load: dig (centrifugal discharge), that is, the hopper is directly dug from the material pile while running at high speed, and the other is inflow (gravity discharge or continuous bucket), that is, the material flows directly into the hopper as it passes through the feed area at a slower speed. The filled hopper then travels up the vertical channel of the elevator, which is usually composed of an enclosed casing to prevent material spillage and contamination. When the hopper reaches the top, it enters the unloading stage. The unloading method mainly depends on the type of hopper, installation method and running speed: centrifugal unloading is suitable for granular, blocky and easy-to-throw materials, and the hopper throws the materials at high speed; gravity unloading is suitable for powdery, blocky, low-viscosity or fragile materials, and the hopper runs slowly and flips to allow the materials to slide out naturally; while the continuous bucket type (chain bucket type) is through the close arrangement of hoppers, the bottom of the previous hopper acts as the chute of the next hopper, so that the material slides smoothly into the discharge port, which is suitable for larger, heavier or highly abrasive materials. Finally, the hopper that has been unloaded will continue to move downward and return to the bottom to prepare for reloading, thus forming a continuous material lifting cycle.

Parameters of Vertical bucket elevator

| Model | Max feed size(mm) | Capacity(T/H) | Lifting speed(m/s) | Belt width(mm) | Lifting height(m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD600 | 70 | 85-142 | 2 | 700 |

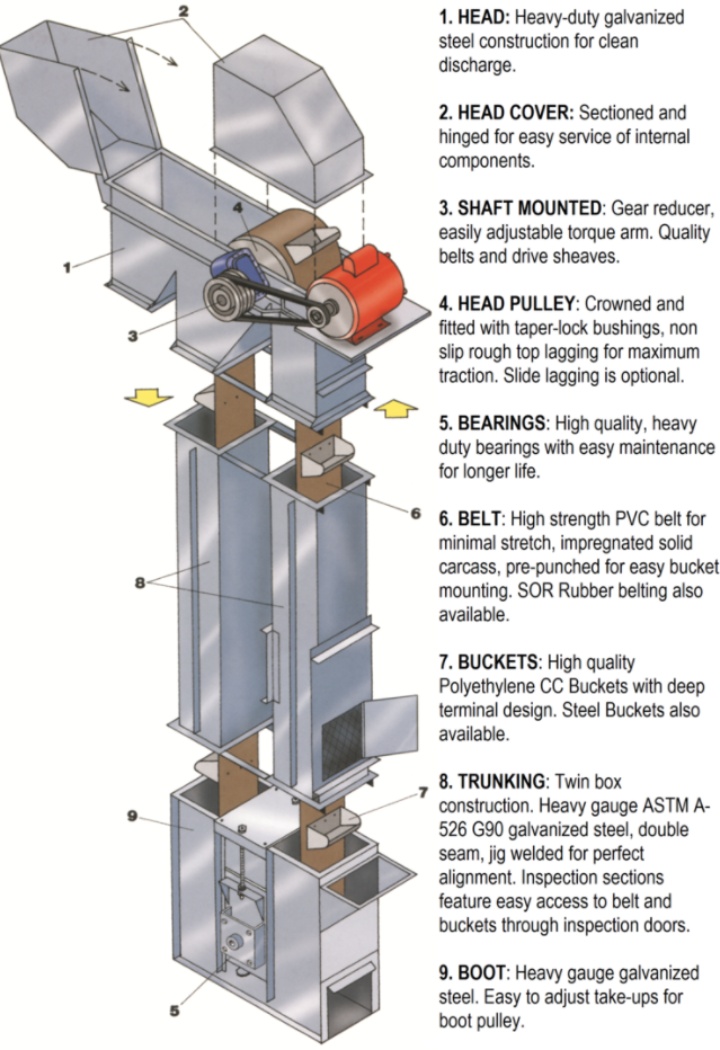

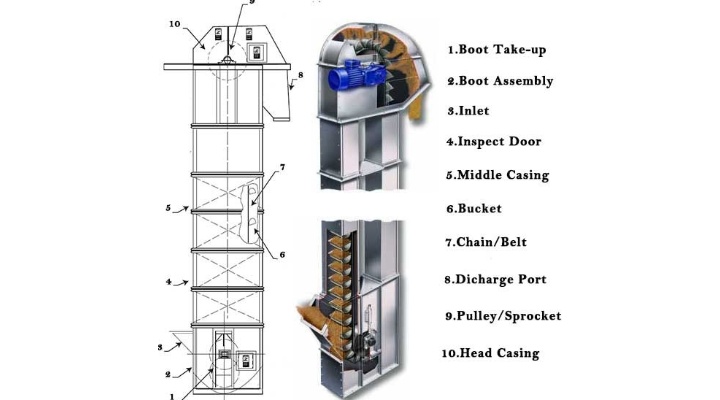

What are the structures of Vertical bucket elevator?

Vertical bucket elevator mainly consists of the following key parts. The first is the casing, which is usually made of metal sheets and is a closed box structure. It not only protects the internal components, but also prevents material leakage. The casing is divided into the bottom base, the middle barrel and the top head. The base includes the feed port, tensioning device and bottom bearing, the head integrates the discharge port, drive device and top bearing, and the barrel is the vertical channel for the hopper and traction member to run, usually composed of multiple sections. The second is the traction member, which is responsible for driving the hopper to move. There are two common types: belts, made of rubber, PVC or other composite materials, suitable for conveying non-abrasive, non-adhesive or irregular materials, characterized by smooth operation and low noise, but with certain requirements for temperature and wear resistance; the other is chains, usually single-chain or double-chain structures, made of high-strength steel, suitable for conveying abrasive, high-temperature, blocky or heavy materials, with large driving force but relatively large noise. The third is the hopper, which is directly fixed on the traction member and is the core component for carrying materials. The hopper is made of various materials, such as carbon steel, stainless steel, plastic, etc., and the selection should be based on the abrasiveness, corrosiveness, food grade requirements and other characteristics of the material. There are also many types of hoppers, including deep/shallow hoppers that affect loading and unloading characteristics, pointed/round hoppers that affect digging and unloading effects, and centrifugal/gravity/continuous hoppers corresponding to different unloading methods. The drive unit is usually located at the top of the elevator, and it includes a motor, a reducer, a coupling, and a drive wheel (or sprocket). The motor provides power, the reducer is responsible for adjusting the speed to meet the required lifting speed, and finally the drive wheel drives the traction member and the hopper to move. Finally, the safety protection device is an indispensable part of the elevator, including an anti-reversal device to prevent the equipment from running in reverse, a deviation switch to monitor whether the belt or chain is deviating and immediately stop the machine, a blocking alarm to monitor whether the discharge port is blocked, a speed monitor to monitor the speed of the traction member, and an explosion-proof device for handling flammable and explosive materials.

What are the applications of Vertical bucket elevator?

Vertical bucket elevator has important applications in many scenarios where bulk materials need to be handled due to its unique vertical conveying method and wide material adaptability. The following are common application scenarios for Vertical bucket elevators:

Vertical connection of production lines: In multi-storey plants or production lines where materials need to be transported to higher processing stages, bucket elevators are ideal for connecting production equipment at different heights. It can smoothly transport materials from one processing unit to the next higher unit to ensure the continuity of the production process.

Filling of high-altitude silos or bins: Many bulk materials need to be stored in tall silos or bins. Bucket elevators can vertically transport large amounts of materials to the top of these high-altitude storage facilities for rapid filling, saving manpower and space.

Recycling and recycling systems: In scenarios where waste materials or recyclable materials need to be transported from the ground to processing equipment (such as crushers, screens or balers), bucket elevators can complete vertical transportation tasks and support automated recycling and recycling processes.

Material transportation in space-constrained environments: Due to its small vertical footprint, bucket elevators are ideal for industrial facilities with limited space. It is an effective solution for material lifting in places where ground space is valuable but vertical space is abundant.

Handling materials of various particle sizes, densities and fluidity: By selecting different types, materials and sizes of buckets (such as deep buckets, shallow buckets, centrifugal buckets, gravity buckets, plastic buckets, steel buckets, etc.), and adjusting the traction components (belts or chains) and operating speeds, bucket elevators can adapt to a variety of bulk materials from fine powders to large pieces, from dry to slightly wet, from free-flowing to less viscous.

Occasions requiring continuous, stable and large-volume transportation: Bucket elevators can operate continuously with high efficiency and handle large amounts of bulk materials, which is essential for processes that require a stable supply or rapid transfer of materials, helping to increase overall production throughput.

Vertical bucket elevator case

Vertical bucket elevators have a wide range of uses, covering the handling of a variety of bulk materials from heavy aggregates to light grains. In the construction and mining industries, vertical bucket elevators are ideal for conveying a variety of aggregates. For example, in concrete mixing plants, they are responsible for lifting raw materials such as sand and gravel from the ground to the storage silo above the mixer to ensure production continuity. In quarries and mines, bucket elevators are used to lift crushed ore or coal vertically to screening equipment or transport vehicles, handling large and often abrasive materials. Their sturdy construction and wear-resistant buckets (usually made of steel) enable them to withstand heavy loads and wear. In agriculture and food processing, bucket elevators are the core equipment of grain handling systems. In grain storage and grain silos, they lift harvested grain from receiving pits to tall silos for storage. In feed mills, bucket elevators are used to transport a variety of grain raw materials for mixing, grinding and pelletizing. Because these materials are often fragile and need to be kept clean, bucket elevators usually use well-designed buckets and closed casings to reduce material breakage and dust pollution, ensuring food safety and product quality. In the cement, building materials and chemical industries, vertical bucket elevators are widely used to transport a variety of powdered materials. For example, in cement plants, they lift raw materials, cement clinker, finished cement, and fly ash from grinders to storage silos or packaging lines. Since these materials are usually fluid and prone to dust, the elevator will be equipped with a more sealed casing to prevent dust from escaping and ensure the effective transportation of materials. In short, the Vertical bucket elevator has become an indispensable logistics link in industrial production with its strong vertical transportation capacity and adaptability to different materials, improving the efficiency and automation level of material handling.

The structural characteristics and operation mode of the Vertical bucket elevator enable it to cope with the vertical transportation requirements of various bulk materials. In the current factory layout and production line, this type of equipment is widely used for inter-layer transfer of materials, high-level storage, and connection between different equipment. When selecting and configuring a Vertical bucket elevator, it is necessary to comprehensively consider factors such as the specific characteristics of the material to be transported, the actual lifting height required, and the space limitations on site.