Horizontal stainless steel mixer for mixing animal feed

Saturday January-31 2026 16:30:24

Horizontal stainless steel mixer for mixing animal feed is made of food-grade 304/316 stainless steel, equipped with a double-screw mixing system to achieve efficient and uniform mixing, and can be equipped with a liquid addition system and a temperature control jacket, supporting PLC intelligent control to achieve automated production. Suitable for all kinds of feed production, with a capacity of 500-5000L that can be customized, it is an ideal solution for improving feed quality and production efficiency.

Advantages of Horizontal stainless steel mixer for mixing animal feed

The horizontal stainless steel mixer is specially designed for animal feed. The double-screw structure ensures mixing uniformity, no residue, easy to clean, and meets GMP standards.

Hygiene and safety: stainless steel material, easy to clean, in line with FDA and GMP hygiene standards.

Low residue: unique unloading structure, reducing material waste and cross-contamination risk.

Energy-saving and durable: frequency conversion control, low energy consumption, low maintenance cost and long service life.

Flexible adaptation: can be matched with vacuum feeder and automatic weighing system to realize fully automated production.

High mixing uniformity: taking the mixer of 500kg/batch as an example, the mixing can be completed in 5-8 minutes, and the uniformity is more than 95%, which is 30% more efficient than traditional equipment.

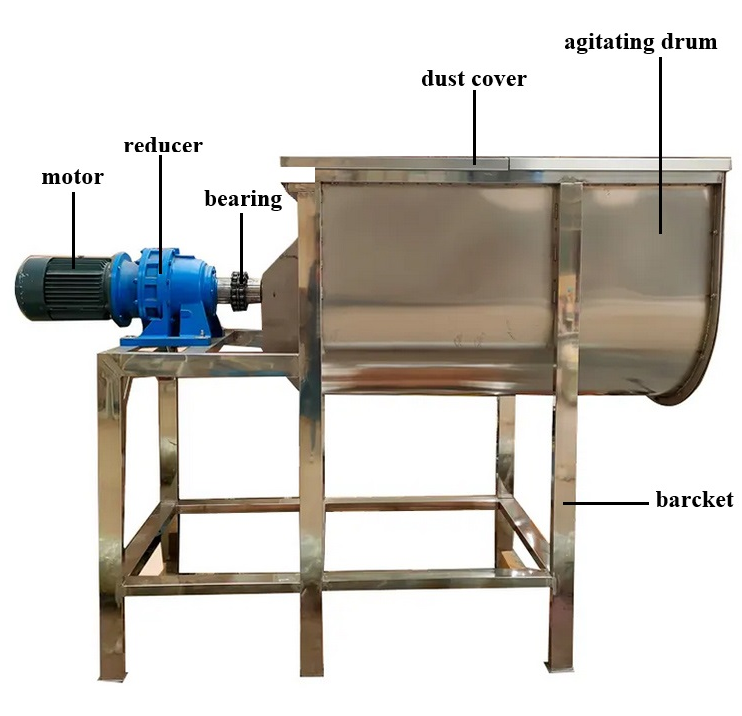

Horizontal stainless steel mixer for mixing animal feed composition structure

Double spiral design + fully sealed 304 stainless steel body, mixing uniformity CV≤5%, its main structure has the following parts.

Stainless steel mixing tank: corrosion-resistant, wear-resistant, in line with food-grade hygiene standards.

Double-axis spiral stirring system: internal and external reverse spiral design to ensure three-dimensional tumbling of materials, mixing uniformity of more than 95%.

Drive device: using variable frequency motor, the mixing speed can be adjusted (10-60rpm) to adapt to different feed formulas.

Discharge door: pneumatic/manual control, fast discharge, low residue (≤0.5%).

Working principle of Horizontal stainless steel mixer for mixing animal feed

When animal feed manufacturers put bulk raw materials such as corn, wheat, soybean meal and additives such as vitamins, amino acids, trace elements, etc. into the U-shaped cylinder of the horizontal stainless steel mixer according to the formula ratio, the mixing system starts. In the early stage of mixing, the axial pushing action of the double spiral belt quickly spreads the material in the cylinder, forming a preliminary circulation convection, so that various materials are fully in contact; as the mixing continues, the shear force generated by the spiral belt breaks the agglomerated materials and promotes mutual friction and dispersion between particles; at the same time, under the combined action of centrifugal force and gravity, the materials continue to roll and diffuse in the radial direction, gradually achieving uniform mixing from local to overall.

Model parameters

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

What types of stirring paddles are there for Horizontal stainless steel mixer for mixing animal feed?

There are various types of stirring paddles for horizontal stainless steel mixers, and different structures are suitable for different material properties and mixing requirements.

Paddle type stirring paddle: The blades are fixed on the shaft by flat or inclined paddles. The blades are mostly straight plates or folded plates, arranged radially or axially, and have a simple structure. It is suitable for simple mixing of granular or powdered materials such as grain feed and premixes.

Ribbon type stirring paddle: It adopts an inner and outer two-layer spiral steel belt structure. The outer layer of the spiral belt pushes the material to one end, and the inner layer of the spiral belt pushes in the opposite direction to form a circulating convection. It is often used for uniform mixing of dry powder or granular materials such as compound feed and additives.

Paddle: It combines the advantages of paddle type and spiral belt type. The outer layer is a spiral belt structure, and the inner layer or the middle is equipped with paddles to enhance the shear and convection effect of the material. It is suitable for materials with high mixing difficulty.

Dispersion disk type stirring paddle: The blade is disc-shaped, with serrated or beveled cuts on the edge, and strong shear force is generated when rotating at high speed. It is mostly used for feed that needs to be refined particles or dispersed liquid addition.

What types of animal feed can be mixed with a horizontal stainless steel mixer for mixing animal feed?

Horizontal stainless steel mixers are widely used in the field of animal feed production due to their efficient mixing performance, corrosion-resistant materials and flexible adjustment functions, and can be adapted to various types of animal feed.

Pig feed: Horizontal stainless steel mixers can evenly mix fine raw materials such as whey powder, fish meal, puffed soybeans, vitamin premixes, etc., to ensure that each feed contains sufficient protein, amino acids and trace elements to meet the needs of rapid growth of piglets.

Egg poultry feed: In order to ensure the egg production rate and egg quality of egg poultry, horizontal stainless steel mixers can evenly mix energy and protein raw materials such as corn, sorghum, rapeseed meal, etc., with calcium carbonate that promotes eggshell quality and premixes that supplement trace elements to ensure that egg poultry intake balanced nutrition.

Meat poultry feed: Meat poultry grows fast and has high requirements for the energy and protein content of feed. The mixer can quickly mix high-energy, high-protein raw materials such as corn, soybean meal, oil, as well as vitamins and antibiotic substitutes that improve immunity.

Cattle feed: For cattle feed, the horizontal stainless steel mixer can fully mix silage, hay, concentrate feed (such as corn, barley, soybean meal) and various additives (such as rumen regulators, mineral lick brick raw materials).

Fish fry feed: Fish fry have strict requirements on the particle size and nutritional content of feed. The horizontal stainless steel mixer can evenly mix high-quality protein raw materials such as fish meal, shrimp meal, wheat protein powder, and vitamins, minerals and attractants that promote the growth of fish fry.

Dog food: Pet dogs have high requirements for the taste, nutrition and safety of feed. The horizontal stainless steel mixer can evenly mix a variety of raw materials such as chicken meal, beef meal, grains, vegetable meal, etc., with functional additives such as hair beautification and intestinal protection.

Optional equipment

This series of horizontal stainless steel mixers is designed for animal feed, and can be equipped with liquid addition system, heating/cooling jacket, PLC intelligent control and metal detection functions.

Liquid addition system: used to evenly add liquid ingredients such as oil and molasses. The system includes a temperature-controlled liquid storage tank (50-500L), a high-precision metering pump (error ±1%) and an atomizing nozzle, which can achieve uniform spraying on the surface of the material.

Temperature control jacket: The heating type (≤200℃) is used for the maturation of fish feed, and the starch gelatinization degree reaches more than 85%; the cooling type (5-15℃) protects heat-sensitive ingredients such as vitamins, and the temperature control accuracy is ±1-2℃.

Intelligent control system: The PLC integrated control system supports formula storage, data traceability and equipment linkage, and has fault self-diagnosis function.

Safety detection device: The metal detector detects ≥0.5mm iron filings, which are automatically removed within 0.5 seconds and installed at the discharge port;

Explosion-proof system: Explosion-proof plate (0.05-0.1MPa), anti-static design (resistance ≤10⁹Ω) and nitrogen protection (oxygen content <12%) to ensure the safety of the dust environment.

Horizontal stainless steel mixer for mixing animal feed manufacturer

Dahan Machinery focuses on the research and development and manufacturing of horizontal stainless steel mixers, strictly following the ISO quality management system to ensure reliable product quality. The equipment is made of 304/316L stainless steel and equipped with a variety of stirring blades. The mixing uniformity exceeds 95%, and the volume covers a variety of specifications, which is suitable for production needs of different scales. The company provides full-process services from pre-sales program planning, installation and commissioning during sales to rapid response after sales. The products are sold well at home and abroad, and have reached long-term cooperation with many well-known feed companies. It can customize production plans for customers based on customer needs.

The horizontal stainless steel mixer has become an indispensable equipment in animal feed production with its powerful mixing ability and wide applicability. Whether it is conventional livestock and poultry feed, or aquatic and special animal feed, it can achieve efficient and uniform mixing through this equipment, providing a solid guarantee for the healthy development of the breeding industry.