Fully automatic packaging machine

Saturday January-31 2026 16:35:38

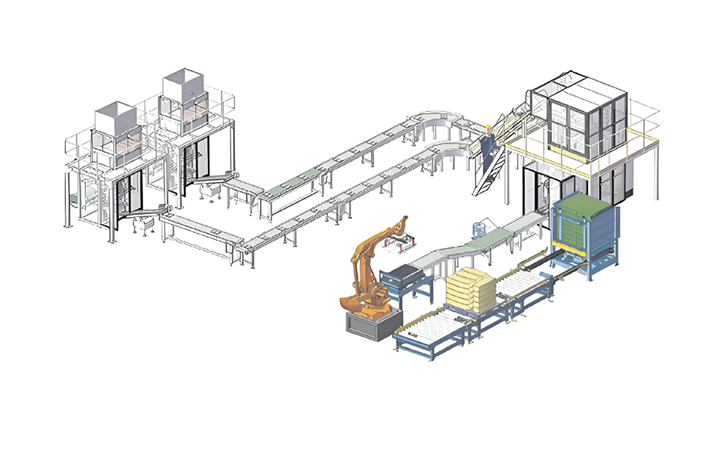

Fully Automatic Packaging Machine automates the entire process of bagging, batching, metering, filling, weighing, sealing, and unloading, eliminating the need for extensive manual labor. It is suitable for a wide range of materials, including powders (flour, milk powder, etc.), granules (cereals, plastic granules, etc.), liquids (edible oils, sauces, etc.), and pastes (creams, ointments, etc.), adapting to the needs of various industries.

The Fully Automatic Packaging Machine offers flexible options for single-head, multi-head, vertical, and horizontal models, depending on production scale and site conditions. The equipment offers stable performance, with a packaging speed of 20-120 bags/minute (depending on material form and machine model), and a packaging capacity ranging from 10g to 50kg, meeting diverse packaging needs, from small-dose samples to large-scale mass production.

Fully Automatic Packaging Machine Process Flow

The Fully Automatic Packaging Machine process flow is as follows: The film roll is pulled into the bag maker via guide rollers to form three-dimensional bags. A metering device then fills the bags with the product. A heat-sealing mechanism heats and seals the bag openings to ensure a tight seal. Finally, a slitting device separates the bags into separate pieces and delivers the finished products.

How does the Fully Automatic Packaging Machine work?

The Fully Automatic Packaging Machine operates by a motor-driven spindle, which, through a transmission mechanism, drives the feeding, metering, forming, filling, sealing, and cutting modules to work in unison. A PLC (Programmable Logic Controller) serves as the core control system, coordinating the actions of each component in real time and working with feedback devices such as photoelectric detectors and sensors to ensure packaging accuracy and consistency. For example, once the packaging film or container is detected, the machine automatically completes the filling and sealing operations, achieving fully automated operation.

The Fully Automatic Packaging Machine primarily involves the following steps

The Fully Automatic Packaging Machine achieves batch and continuous packaging operations through a fully automated process encompassing automatic feeding, precise metering, forming and positioning, filling, sealing and cutting, and finished product conveying.

Automatic Feeding: Materials enter the metering unit via conveying equipment (such as a screw feeder or vibrating hopper);

Precise Measuring: Material weight or volume is automatically measured according to set parameters;

Forming and Positioning: The packaging film is formed into a bag or aligned with the packaging container by a former or positioning system;

Filling: The material is filled into the package at the set amount;

Sealing and Cutting: The package is sealed using heat or cold sealing techniques, and then cut to size or coded;

Finished Product Conveying: After packaging, the package is automatically conveyed to the next process or boxing area.

Fully Automatic Packaging Machine Technical Parameters Reference

| Equipment Configuration | Parameter Value |

| Packaging speed | 20-100 bags/minute |

| Measuring range | 100g to 5000g |

| Measuring accuracy | ±0.2%~±1.0% |

| Applicable bag width | 80mm-220mm |

| Power supply specifications | 220V/380V, power about 2.5kW |

| Air pressure requirement | 0.6MPa, air volume 0.3m³/min |

| Hopper Capacity | about 1500×800×1700mm |

| Applicable materials | granules, powders, flakes and small blocks |

| Control system | PLC+servo drive, touch screen operation |

Fully Automatic Packaging Machine Applications

In the food industry, the Fully Automatic Packaging Machine can weigh, seal, and date snacks, rice, noodles, and frozen foods. For example, it can precisely package potato chips into small bags to prevent contamination from human contact. In the pharmaceutical industry, it can package capsules and tablets in single doses or batches, ensuring the seal and ensuring the expiration date. In the daily necessities industry, it is used for filling and capping liquid products such as laundry detergent and shampoo, ensuring precise dosage. In the building materials industry, it is suitable for quantitative packaging of powdered/granular materials such as cement and paint, reducing dust leakage. Furthermore, in the electronic components and medical device industries, it can also meet the sophisticated packaging needs through customized accessories.

Fully Automatic Packaging Machine Solutions

The Fully Automatic Packaging Machine solution encompasses multiple aspects: First, customized models designed based on the specific characteristics of industries like food and pharmaceuticals, and for material forms such as granules and liquids, ensuring contamination prevention for food and GMP compliance for pharmaceuticals. Second, intelligent integration, with an embedded PLC control system and touch screen, coupled with a weighing and detection module to eliminate defective products, and integrated with the MES system for data traceability. Third, efficient production lines, combining loading, filling, and sealing modules for optimized flow, boast a production capacity of 30-200 bags per minute and accommodate a wide range of packaging formats. Fourth, after-sales support, including installation training, remote maintenance, and genuine spare parts, minimizes downtime losses.

With its high efficiency, precise control, and intelligent capabilities, the Fully Automatic Packaging Machine has become an indispensable key piece of equipment in modern industrial packaging. It not only enhances production automation but also ensures aesthetically pleasing and consistent product packaging. Through flexible technical parameter settings and high-performance PLC system integration, the equipment can adapt to diverse material and packaging requirements.