Poultry feed mixer

Use screw rotation to mix various feed ingredients (such as corn flour、premix、vitamin additives, etc.) evenly to improve feed utilization

Energy saving\high efficiency\short time

Mixing time: 5-10 minutes

One-time mixing: 100-3000 (kg)

Capacity: 200L-50,000L

Material: carbon steel\304L stainless steel\316L stainless steel

Application: Various processing activities in the food, pharmaceutical, chemical, pigment and coating industries

Promise: free shipping/5-day delivery/30-day return and exchange/customization`

What is a poultry feed mixer?

Poultry feed mixer is a kind of equipment designed for farms to evenly mix poultry feed raw materials (such as corn, soybean meal, fish meal, vitamins, etc.) to meet the nutritional needs of poultry such as chickens, ducks, geese and other poultry at different growth stages. Poultry feed has complex characteristics, including nutritious feed (50-60%), protein feed (20-30%), additional and additives (2-5%), and large differences in particle size, density and humidity, requiring a mixer to efficiently mix uneven nutrition.

The mixer drives the raw materials to turn, spread and shear in the bin through high-speed rotating spiral blades or stirring dragons (300-500 rpm). The vertical attachment is suitable for small farms. The mixing degree is uniform and reaches more than 95%. The direct effect of stirring affects the palatability of feed to ensure the growth efficiency of poultry. High-quality containers can avoid stratification of raw materials, and each portion of feed is nutritionally balanced, reducing picky eating.

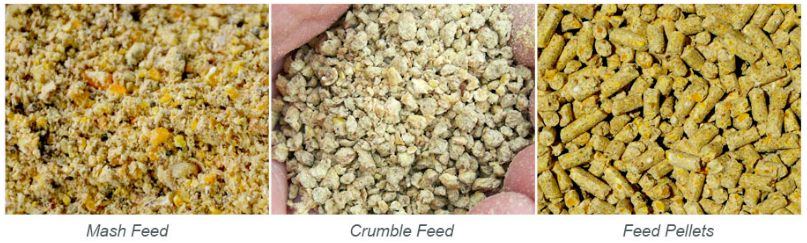

What are the mixtures of poultry feed?

The mixtures of poultry feed are carefully formulated to meet the comprehensive nutrition required for poultry growth and production. They mainly contain energy feeds such as corn, wheat and their processing by-products (rice bran, wheat bran), as well as vegetable oils or animal fats, which provide energy for poultry activities and production.

The second is protein feed, the core of which is soybean meal, but also includes plant proteins such as rapeseed meal and sunflower meal, as well as animal proteins such as fish meal and meat and bone meal, which provide amino acids to support muscle and organ development. In addition, vitamins are added in the form of compound premixes to ensure the normal operation of various physiological metabolisms of poultry. Finally, various feed additives, such as amino acids, enzyme preparations, probiotics, etc., are added to improve feed utilization, promote growth, improve health and product quality. These ingredients are mixed in scientific proportions to form complete feed, ensuring that poultry obtains balanced nutrition and achieves optimal production performance.

Types of poultry feed mixers

1.Vertical mixer

Principle: The feed is lifted upward by the spiral auger at the bottom, and after reaching the top, it is thrown and dropped to the surroundings, and repeatedly mixed under the action of gravity

Scope of application: small and medium-sized farms, family farms, where the mixing requirements are not extremely fine and the budget is limited

Advantages: gentle mixing, little damage to feed particles, and relatively low price

Output: 500-1000 kg/batch

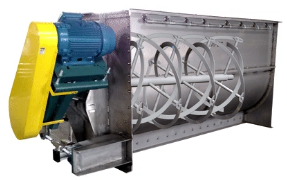

2.Horizontal mixer

Principle: There are two layers of spiral ribbon blades rotating in the inner and outer layers in the barrel, which push the material to do complex convection movement in the horizontal and vertical directions at the same time, and mix quickly

Applicable scenarios: medium and large farms, feed processing plants, occasions with high requirements for mixing uniformity, efficiency and output

Advantages: short mixing time (usually 3-8 minutes/batch), strong adaptability to various forms of raw materials (powder, short fiber, a small amount of liquid)

Output: 500-2000 kg/batch

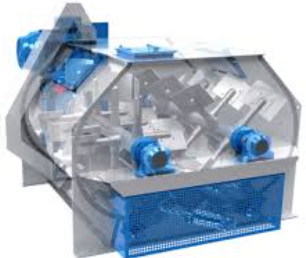

3.Double-shaft mixer

Principle: Multiple sets of blades are installed on two parallel shafts, and the blades rotate at high speed to cut, sprinkle, and convectively mix the materials.

Applicable scenarios: large feed mills, places with extremely high requirements for mixing uniformity and speed and sufficient budget

Advantages: fastest mixing speed (usually 1-3 minutes/batch), extremely high mixing uniformity.

Output: 100-3000 kg/batch

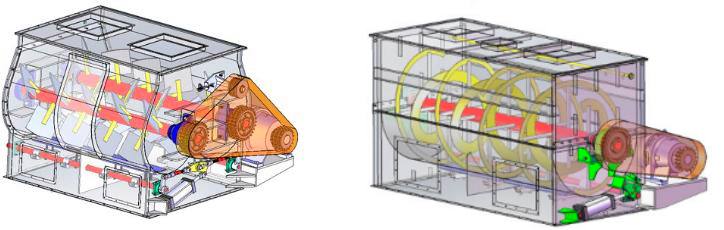

What is the working principle of the poultry feed mixer?

The poultry feed mixer uses mechanical force to achieve uniform mixing of feed, and its core is the motor-driven mixing system.

When working, the motor drives the mixing shaft and blades to rotate through the reducer. The rotation of the blades produces shear, convection and diffusion effects, so that raw materials such as corn, soybean meal, and additives are fully mixed in the mixing chamber. Some models adopt a dual-axis reverse rotation design to form a cross-overlapping weightlessness zone, where the material floats up and circulates continuously in all directions to quickly achieve uniform mixing.

In addition, some mixers also integrate a crushing function, using hammers to crush materials at high speed, and control the particle size through a screen to achieve integrated crushing and mixing. The mixed feed is accurately discharged through the discharging mechanism to ensure balanced nutrition and improve feed quality.

What are the advantages of poultry feed mixers?

Poultry feed mixers are equipment that mixes raw materials such as grains, soybean meal, fish meal, additives, etc. in proportion by mechanical force. Its main function is to fully mix different types of feed raw materials (such as grains, soybean meal, fish meal, premixes, etc.) to ensure that poultry obtains balanced nutrition.

① Even mixing: Mix various powdered and granular raw materials (such as corn, soybean meal, bran, stone powder, premixes, vitamins, minerals, amino acids, etc.) and possible liquid additives (oils, enzymes, water) fully and evenly.

② Improve feed utilization: Even mixing ensures that each portion of feed contains all the nutrients in the formula to avoid picky eating or uneven nutrient intake of poultry.

③ Ensure nutritional balance: For feeds that require the addition of trace ingredients (such as premixes), mixers are the key to ensuring the uniform distribution of these expensive ingredients.

④ Improve feed palatability: Some mixers can also process the feed to a certain extent (such as crushing and rolling) during the mixing process to improve the particle size of the feed, making it more in line with the feeding habits of poultry and improving palatability.

Technical parameters of poultry feed mixer

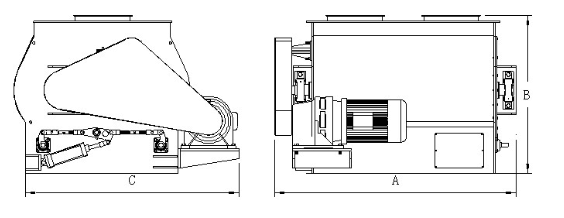

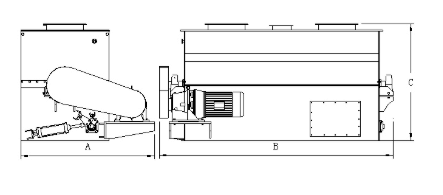

| Model | Mixing method | Capacity (kg/batch) | Motor power (kW) | Mixing time (min) | Dimensions (mm) | Weight (kg) |

| HJJ-100 | Horizontal screw belt mixing | 100 | 1.5 | 8~10 | 1200×600×1000 | 120 |

| HJJ-300 | Horizontal double screw belt | 300 | 3.0 | 10 | 1800×750×1200 | 250 |

| HJ J-500 | Horizontal spiral stirring | 500 | 4.0 | 7~10 | 2200×850×1300 | 350 |

| HJJ-1000 | Horizontal double-shaft paddle | 1000 | 5.5~7.5 | 6~8 | 2800×1000×1500 | 600 |

| HJJ-2000 | Dual-shaft high-efficiency stirring | 2000 | 11 | 6 | 3400×1300×1800 | 950 |

| LJJ-300 | Vertical spiral stirring | 300 | 2 .2 | 10~15 | 1400×900×2100 | 220 |

| LJJ-500 | Vertical spiral stirring | 500 | 3.0 | 12~15 | 1650×1000×2200 | 300 |

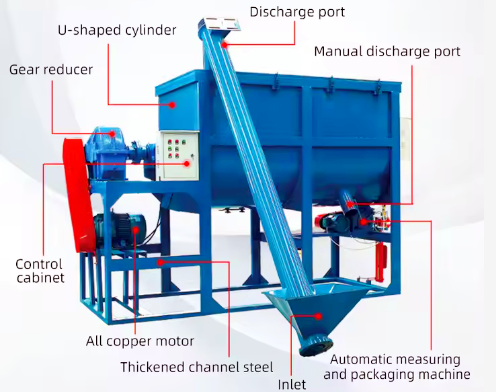

Structure of poultry feed mixer

Feeding port: input corn flour, soybean meal, additives and other raw materials, can be single or multiple ports, some models with automatic batching system

Mixing chamber: main mixing cylinder, raw materials are mixed in this room, generally made of carbon steel or stainless steel, Anti-corrosion and anti-rust

Agitator shaft/agitator blade: key components, common forms include spiral ribbon type, paddle type, double-shaft counter-rotation type, etc., to achieve multi-dimensional directional mixing

Motor and reducer: provide power source, drive the agitator shaft to rotate through sprockets, belts or gears

Discharge port: feed is discharged from here after mixing, in the form of manual door, electric door or pneumatic door

Frame and support structure: support the whole equipment, maintain stable operation, some models are equipped with shock absorbers

What is the purpose of poultry feed mixer?

The main purpose of poultry feed mixer is to accurately and efficiently mix a variety of feed raw materials into uniform complete feed to meet the nutritional needs of poultry at different growth stages.

In large-scale poultry farms, mixers are the core equipment of feed processing lines, used for batch production of broiler feed, laying hen feed, breeder feed, etc. These large mixers can process tons or even tens of tons of materials, ensuring that the huge daily feed demand is met, and strictly controlling the feed quality, which directly affects the production performance and disease resistance of poultry.

For small and medium-sized farmers or family farms, they can purchase basic raw materials according to the breed, age and feeding goals of their own poultry, and use small and medium-sized mixers to mix feed by themselves, thereby reducing feed costs and being able to adjust the formula more flexibly to meet the specific needs of poultry, such as quickly adjusting nutrition or adding specific functional ingredients in specific seasons or when responding to disease challenges.

In addition, feed production companies are the largest users of mixers, and they use a variety of large, highly automated mixers to produce a variety of poultry compound feeds. These companies have extremely high requirements for the mixing uniformity, efficiency and stability of mixers to ensure product quality and market competitiveness.

How to choose a suitable poultry feed mixer?

For the vast majority of small and medium-sized poultry farms: vertical mixers are an economical and practical choice, especially for mixing pellets or sensitive to pellet damage, limited budgets, and single-phase electricity. Pay attention to choosing the right capacity.

For medium-sized and larger farms, there are high requirements for mixing efficiency and uniformity or more liquid needs to be added: horizontal ribbon mixers are a better choice. Although the initial investment is higher, the high efficiency and uniformity of the feed utilization and production efficiency improvement usually cover the cost quickly.

For large-scale breeding enterprises or feed mills, large horizontal ribbon or high-performance twin-shaft paddle mixers can be considered according to specific needs and budgets.

Poultry feed mixer price

Poultry feed mixers are key equipment used to mix feed ingredients in animal husbandry. Their prices vary depending on type, capacity, brand and function.

| Model | Type | Mixing capacity | Power | Reference price |

| 500 type vertical mixer | vertical | 500kg | 3kW | $70 - $5,000 USD |

| 1000 type horizontal mixer | horizontal | 1 ton | 5.5kW | $160 - $30,000 USD |

| Double-shaft 2-ton mixer | Double-shaft horizontal | 2 tons | 11~15kW | $300 - $60,000 USD |