The price of the ribbon mixer

Friday May-30 2025 16:38:56

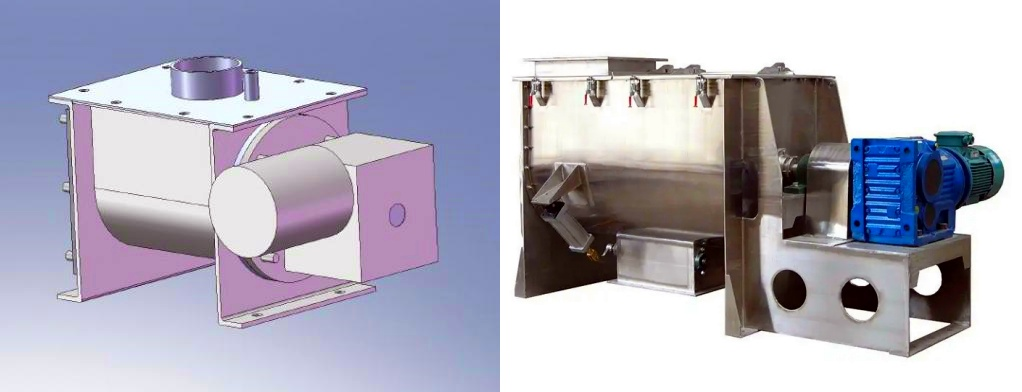

The ribbon mixer is a mixing device that uses spirally arranged ribbons in the barrel to stir materials. Its characteristics are that the relative movement of the inner and outer layers of the ribbons forms convection and shearing to achieve material mixing. The ribbon mixer can mix powdery and granular materials well, especially for occasions with low requirements for mixing uniformity but large output, such as dry mortar, feed, chemical powder, etc.

The mixing effect mainly depends on the structure and speed of the ribbon, which can make the material move axially and radially in the barrel to achieve a certain mixing uniformity. For production scenarios that require high mixing accuracy and small batch differences, the ribbon mixer can complete mixing in a short time and reduce material residues. It is widely used in food, chemical, building materials, medicine, feed and other industries.

The price of the ribbon mixer varies greatly due to its model, material, volume, and functional configuration. The main factors affecting the price include volume size, material selection, configuration requirements, etc.

① The common volume range of the ribbon mixer ranges from 100L to 5000L. The larger the volume, the more materials required for the equipment, the higher the processing cost, and the more expensive the price.

Basic model (laboratory/small-scale production): small capacity (50-500L), mostly made of carbon steel or ordinary stainless steel, suitable for simple mixing of powder and granular materials. Usually between US$100 and US$500.

Mid-range model (industrial general type): stainless steel material (304/316L), strong corrosion resistance; capacity 500~2000L, support customized configuration (such as heating, cooling, vacuum function); applicable industries: food, chemical, building materials, etc. The price is generally between US$500 and US$2000.

High-end/customized models (special needs) (2000~5000L and above): explosion-proof design, special coating or non-standard size customization; capacity 500~2000L, suitable for pharmaceutical, high-viscosity materials (such as putty paste), hazardous materials handling and other industries. The price is usually above US$2,000, and some large and high-configuration equipment may exceed US$50,000.

② The price of the ribbon mixer varies greatly according to the material. The price of the carbon steel ribbon mixer is relatively low and is suitable for occasions with low hygiene requirements. Stainless steel (such as 304, 316L) is corrosion-resistant, clean and hygienic, and has a higher price. It is often used in the food, pharmaceutical and chemical industries. The equipment is lined with anti-corrosion materials or special alloy steel, and the price is higher, which is suitable for corrosive materials.

③ Whether it has a heating/cooling jacket; whether to add a spray device, frequency conversion control system, hydraulic discharge, etc.; the drive motor power, reducer brand, shaft seal structure, etc. will affect the price.

Price reference range of ribbon mixer

| Volume (L) | simple carbon steel machine price (US dollars) | standard 304 stainless steel machine price (US dollars) | high-end customized machine price (US dollars) |

| 100 | 500~800 | 900~1500 | 1500~2000 and above |

| 300 | 700~1000 | 1300~2000 | 2000~30000 |

| 500 | 900~1500 | 1800~2800 | 3000~40 000 |

| 1000 | 1500~2500 | 2500~4000 | 4000~60000 |

| 2000 | 2500~4000 | 4000~7000 | 7000~10000 and above |

| 5000 | 6000~9000 | 9000~1300 | 1300~18000 and above |

Note: The above prices are only for market reference, excluding tax and freight. The specific prices need to be confirmed with the manufacturer according to user needs.

Ribbon mixer is a horizontal mixing equipment commonly used for mixing powders with powders, powders with a small amount of liquid. It is equipped with double-layer or multi-layer spiral ribbon agitators, which can form convection, shear, diffusion and other composite mixing movements in the material cylinder, thereby achieving efficient and uniform mixing effect. The equipment has the characteristics of simple structure, fast mixing speed, high mixing uniformity, large loading coefficient, etc. It is suitable for dry powder and granular materials with good fluidity and similar particle size, such as chemical raw material mixing (such as powder, granules, additives), food industry (such as flour, seasoning, milk powder), pharmaceutical industry (such as powder, granules), building materials (such as dry mortar, putty powder), agricultural fertilizer

| Model | LHY-0.25 | LHY-0.5 | LHY-1 | LHY-1.5 | LHY-2 | LHY-3 | LHY-4 | LHY-6 | LHY-8 | LHY-10 |

| One-time mixing (kg) | 100-150 | 200-300 | 400-600 | 600-900 | 800-1000 | 1200-1800 | 1600-2400 | 2400-3600 | 3200-4800 | 4000-6000 |

| Mixing time (min) | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 | 8-20 |

| Mixing speed (r/min) | 60 | 55 | 45 | 40 | 35 | 25 | 25 | 20 | 15 | 15 |

| Motor power (kw) | 3-5.5 | 4-11 | 7.5-15 | 11-18.5 | 15-22 | 18.5-30 | 22-37 | 37-55 | 37-55 | 45-75 |

| Weight (kg) | 500 | 900 | 1800 | 2500 | 3200 | 4100 | 5100 | 6300 | 7500 |

How to get an accurate quote?

Material characteristics: What material is it? (Powder, granules, viscous materials? Is it corrosive, toxic, flammable and explosive?)

Mixing capacity: How much volume/weight of material needs to be mixed per batch? (Note the bulk density of the material)

Process requirements: Is heating/cooling required? Is vacuum required? Mixing uniformity requirements? Mixing time requirements? Is liquid spraying required? Discharging requirements?

Material requirements: What material must be used for the part in contact with the material? (304, 316L, carbon steel?)

Budget range: (optional, but helpful for suppliers to recommend suitable solutions)

Clarify the physical properties of the mixed materials (particle size, fluidity, flammability and explosion, etc.), determine the batch output and daily production needs, and select the appropriate volume; select the appropriate material according to the hygiene standards and use environment; give priority to models with inverters, which are conducive to controlling the mixing uniformity; compare prices with multiple suppliers and check the prototype or process testing. If you have any questions about our products or want to inquire about prices, you can come to our relevant technicians.