Coarse crusher

The processing capacity ranges from 1 ton/hour to 1000 tons/hour to meet the needs of production of different scales

The feed particle size can reach 120-1500mm, and the output particle size can be adjusted from 10-400mm

Applicable to limestone, quartz stone, iron ore, bluestone, river pebbles, granite, basalt and other materials

Sturdy and durable structural design, key components are made of high-strength alloy materials

What is a Coarse crusher?

The Coarse crusher is the first key equipment in the material crushing production line, mainly used for primary crushing of various bulk materials. Our Coarse crusher series is manufactured with advanced crushing technology and high-quality materials, which can efficiently process coarse materials of various hardness, viscosity and shape, and provide ideal material particle size for subsequent processing procedures.

Our Coarse crusher is widely used in metallurgy, mining, chemical industry, cement, construction, refractory materials and ceramics industries, providing customers with efficient coarse crushing solutions

What types of coarse crushers are there?

| Type | Applicable materials | Processing capacity | Main features |

| Jaw Coarse Crusher | Ore, rock, construction waste | 1-1000t/h | Simple structure, easy maintenance, large crushing ratio |

| Cyclone Coarse crusher | Large ore, high hardness material | 500-1200t/h | Large processing capacity, high degree of automation |

| Solid waste treatment Coarse crusher | Domestic garbage, industrial waste | 10-60t/h | High torque, impact resistance, adaptability to complex materials |

| Medicine and food Coarse crusher | Medicine, food raw materials, plastics | 8-5000kg/h | Sanitary design, adjustable particle size |

What are the advantages of coarse crusher?

Powerful crushing capacity: Our coarse crusher adopts advanced crushing technology and is made of high-strength wear-resistant materials to ensure efficient and stable crushing effect.

Strong and durable structure: The equipment structure is reasonably designed, and the key components are optimized and reinforced, which can operate stably for a long time and reduce maintenance costs.

Wide applicability: Our coarse crusher can handle various types of coarse materials to meet the crushing needs of different industries.

Flexible configuration scheme: We provide coarse crushers of various models and specifications, and can be customized according to the actual needs of customers.

How does a coarse crusher work?

Working principle of jaw coarse crusher: It adopts the flexural extreme pressure working mode. The motor drives the pulley and the eccentric shaft to rotate through the V-belt, so that the movable jaw moves along the predetermined trajectory. The movable jaw plate makes periodic reciprocating swings against the fixed jaw plate. When the jaw plates are close, the materials are squeezed, split and bent between the two jaw plates; when the jaw plates leave, the crushed materials fall down by their own weight, and the materials that are not fully crushed move down and wait for the next crushing.

Working principle of gyratory coarse crusher: the crushing cone is driven to oscillate through the eccentric sleeve, so that the surface of the crushing cone is sometimes close to and sometimes away from the inner surface of the fixed cone. The material is crushed by multiple squeezing, bending and shearing in the crushing chamber. Smaller materials are discharged from the discharge port, and larger materials continue to be crushed until they reach the required particle size.

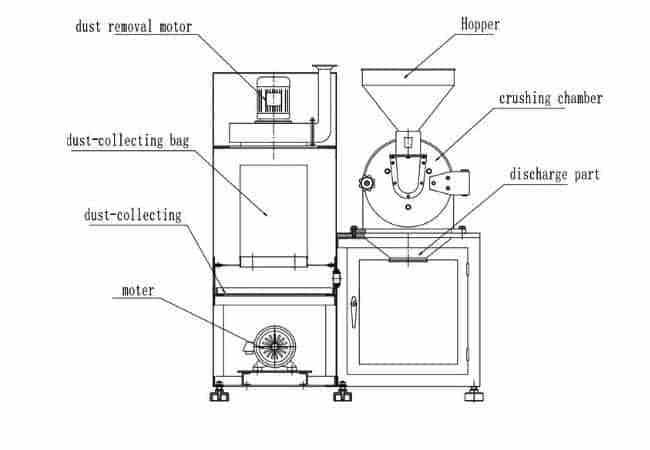

Working principle of vertical coarse crusher: The vertical coarse crusher commonly used in the pharmaceutical and food industry crushes materials through the impact and shearing action between the high-speed rotating blade and the fixed knife. The material enters the crushing chamber from the feed hopper and automatically flows to the outlet under the action of centrifugal force. The particle size of the discharge can be adjusted by replacing the screens of different specifications.

What coarse materials can the coarse crusher crush?

Our coarse crusher has a strong crushing capacity and can efficiently process various types of coarse materials, including but not limited to:

Ore: river pebbles, granite, basalt, limestone, iron ore, copper ore and other types of ore raw materials.

Construction waste: concrete blocks, bricks and tiles, waste asphalt, etc.

Industrial waste: large scraps, plastic blocks, rubber blocks, wood, etc.

Chemical raw materials: partially agglomerated or large-particle chemical raw materials.

Agricultural waste: large straw, branches, etc. (applicable to some models).

No matter what type and hardness of your raw materials, we have the right coarse crusher model to meet your needs. If you have special crushing needs, our professional team can also provide you with customized solutions.

Sugested Products

Related news

Sieving Machine

Conveying equipment

Bucket Elevator

Mixer

Packaging Machine

E-mail:

sale@xxdahan.com

WhatsApp:

+86 15836198876

Add:

Yanjin county forest park gate to the west 1000 meters north road

Micro-crushing machine

Micro-crushing machine